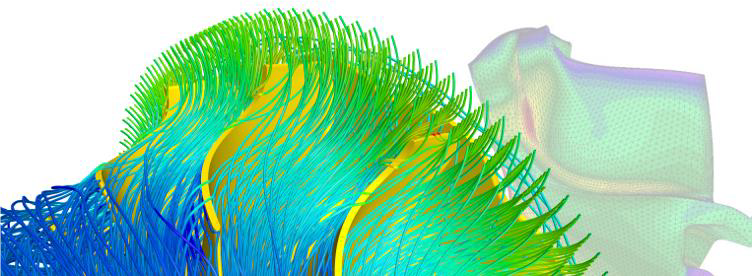

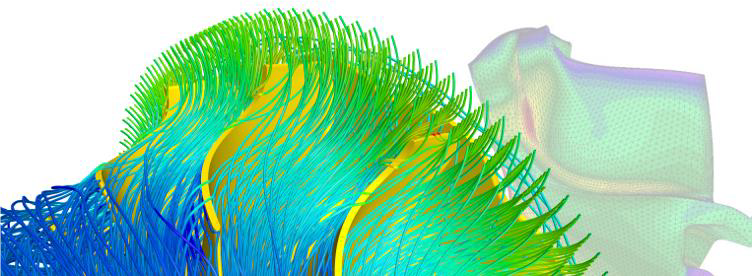

CAESES is a flexible and powerful platform for the design of turbomachinery blades, including advanced endwall optimization methods. All parameterized blade models can be closely linked to meshing and simulation tools to run automated CFD simulation analysis and optimization design. Application cases include turbochargers, steam turbines, fans and pumps – including axial flow, centrifugal or mixed flow.

Internationally renowned companies such as Siemens, Toyota, MTU, KSB, Spencer Turbine and IHI are using CAESES to design turbomachinery components.

Why CAESES?

- Flexible and stable parametric model;

- High degree of customization, open to all details and fully integrated into existing workflows;

- Comprehensive consideration of geometrical/manufacturing constraints in model setup;

- Intelligent reduction of the number of parameters;

- Provides the possibility to adjust model details comprehensively, e.g. to better control local flow phenomena such as cavitation or vortices;

- One-time pre-processing for all design variants;

- Everything is automated for efficient shape optimization;

- Super-fast technical support from the CAESES support team.

Blade design – efficient and flexible

The blade model in CAESES can be created quickly manually or automatically. Create single blades or separate blade models, using existing templates or customizing them, for example:

- Create arbitrary parametric 2D profiles, including automated fitting based on existing blades;

- Based on arbitrary meridian profiles (imported data, created parametric curves), 2D blade sections can be mapped onto 3D flow surfaces;

- Define arbitrary leading and trailing edge shapes, including circular, elliptical, blunt, curved;

- Any mid-arc definition method, based on beta or theta angles, i.e. blade airflow angle or blade profile wrap angle, etc.;

- Any thickness distribution definition (imported data, parametric curves, mathematical formula definition);

- Rounded corner control based on radius (constant, variable) and taking into account stress and structural constraints;

- Advanced 3D surface generation technology can generate high-quality shapes and determine feasible design solutions.

Parametric geometry model

For automated CFD analysis of new designs, CAESES can provide automatically processed parametric geometry, such as periodic fluid domains, which can be adjusted to the blade shape and automatically generate the mesh without manual work.

Fully automated CFD and stress analysis in one cycle

CAESES’s advanced and robust CAD capabilities allow you to easily create parameterized periodic solid area models, including special star structures, etc. Thus, in one cycle, stress analysis and CFD analysis can be performed simultaneously. Using the models provided by CAESES, a large part of the manual work can be saved by combining these two processes in one automated cycle.