Aero-engine is the core of modern aviation industry, and its performance directly affects the speed, maneuverability and range of aircraft. In order to meet the needs of turbine blades under extreme operating conditions, especially high temperature and pressure environments, nickel-based superalloys have been rapidly developed since the late 1930s. In this paper, we will review the development of nickel-based superalloys from Nimonic series to directional solidification and single crystal superalloys, discuss how these materials can gradually improve the temperature resistance and mechanical properties of turbine blades, promote the continuous improvement of aero engine performance, and look into the future development trend.

In order to meet the needs of hot-end components for turbojet engines, nickel-based superalloys have been developed since the late 1930s. In 1939, the British Mond Nickel company developed Nimonic75 alloy, and then developed Nimonic80 alloy by adding Al and Ti elements. In 1942, Nimonic80 was successfully used in turbine blade materials, which was the first application of γ’-Ni3(Al, Ti) phase reinforced materials. After that, a series of alloys such as Nimonic80A, Nimonic90, Nimonic95, Nimonic100 and Nimonic115 were formed by adding B, Zr, Co and other elements to further improve the alloy properties. The development path of superalloys in the United States and the former Soviet Union is similar to that in the United Kingdom.

In the mid-1940s, Halliwell developed K42B alloy for the manufacture of piston aero engines. Subsequently, PW Company, CE company and special metals company developed Waspalloy, M252 and Udimet500 alloys respectively in the 1950s, and on this basis formed Inconel, Mar-M and Udimet series alloys. These alloys are made into parts such as turbine blades by forging, rolling and other processes, and are called deformation superalloys. However, with the development of the aviation industry, the blades need to withstand higher working temperatures and strengths, as well as the increase in structural complexity, resulting in deformation superalloys that cannot meet the demand, which gave birth to casting superalloys.

In the 1950s, the emergence of vacuum melting and investment precision casting technology greatly improved alloy properties and casting quality, opening the “casting era”. Many high performance nickel-based cast alloys such as IN100, B1900, ЖC6, MAR-M200, IN713, MAR-M002 and Rene125 have been introduced. The development of cast nickel-based superalloys can be divided into three stages: in the initial stage, mainly through adjusting the alloy composition to meet the design requirements; Medium alloy composition and casting process jointly determine the material properties. In the later stage, due to the temperature approaching the limit, new processes such as directional solidification and single crystal technology are mainly relied on to improve the performance.

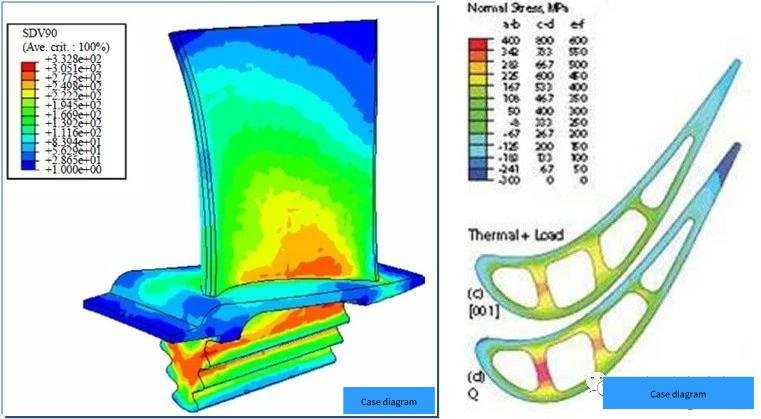

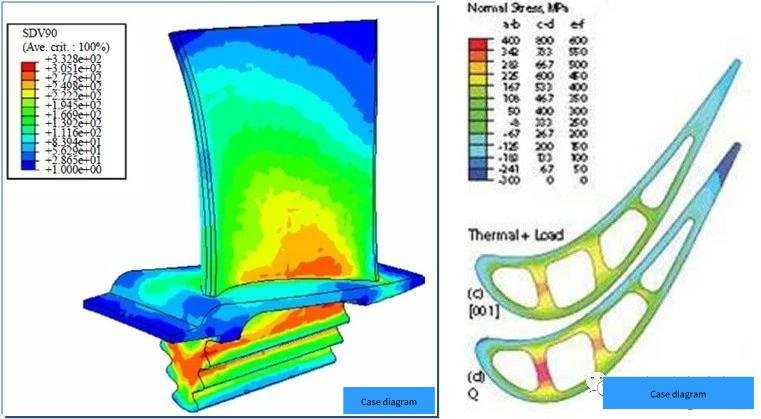

Although the strength of ordinary casting superalloy is improved, due to the existence of multiple grain boundaries in its polycrystalline structure, there are more impurities at the grain boundaries, the atom diffusion is fast and the arrangement is irregular, which becomes a weak link in high temperature service. At higher temperatures, cracks tend to start and propagate at transverse grain boundaries first. It is found that the middle temperature plasticity of Mar-M200 isaxed alloy is very low, and the so-called “plastic trough” problem appears.

In order to overcome the negative effects of transverse grain boundaries and improve the mechanical properties of blades at high temperature, directional solidification technology was developed to avoid the formation of transverse grain boundaries. Based on this technology, directionally solidified superalloys with eliminating transverse grain boundaries and single crystal superalloys without grain boundaries have been developed successively. At present, the directionally solidified superalloy has been developed to the fourth generation, and the temperature bearing capacity of each generation is nearly 30℃ higher than that of the previous generation. Single crystal superalloy has progressed to the sixth generation. The successive emergence and application of generation after generation of single crystal superalloys have significantly improved the performance of aeroengines and gas turbines, and become the most promising advanced materials.

In short, the development of nickel-based superalloys is closely related to the progress of aero engines. From the initial deformation superalloy to the later casting superalloy, and then to directional solidification and single crystal superalloy, this series of technological advances have greatly promoted the performance of aviation engines. In the future, with the development of new materials and technologies, nickel-based superalloys will continue to play an important role in supporting the continued innovation and development of the aviation industry.

Thank you for your interest in our company! If you have any questions, suggestions or cooperation intentions, we are more than happy to help you. Please contact us in the following ways:

- WhatsAPP:+86 135 4409 5201

- E-mail:peter@turbineblade.net

- Address:4E137, 4th Floor, Building 210, Tairan Science Park, Tairan 4th Road, Tian ‘an Community, Shatou Street, Futian District, Shenzhen. China