In the industrial field, the aero engine has the title of crown pearl, which can be seen that the importance of aero engine. In the engine, the turbine blade as an extremely important part, its main role is to convert energy, that is, heat energy into mechanical kinetic energy. However, the development of turbines is very difficult, and a lot of manpower, material resources and financial resources need to be invested in the development process. At this stage, with the development and successful production of new engines, production costs will inevitably increase for manufacturers of turbine blades of aero-engines. In order to reduce production costs, relevant enterprises need to reduce the replacement of turbine blades as much as possible. To achieve this goal, they must strengthen the testing and maintenance of turbine blades. Extend the service life of turbine blades. The following article analyzes the relevant detection technologies of turbine blades, hoping to provide reference for relevant enterprises.

1. Cleaning treatment of aero engine turbine blades

During the normal operation of the aircraft engine, a large amount of aviation fuel is burned, and after the combustion of these fuels, a large amount of deposited waste will be formed. These sediments will undergo oxidation reaction due to long-term high temperature, thus producing a certain corrosion effect on the blades. Moreover, these sediments will be attached to the surface of the engine blades. It will increase the thickness and weight of the engine blade, and with the increase of the thickness and weight of the engine blade, it will not only affect the safety performance detection of the blade, but also may lead to engine blockage, resulting in reduced engine operation efficiency. Therefore, before testing the turbine blades of an aeroengine, the blades must be cleaned.

The carbon deposits generated in the normal operation of the aeroengine are very hard because they are affected by high temperature and pressure when they are formed, and because these impurities will be closely combined with the blades. Therefore, at this stage, in order to better clean up carbon impurities, an efficient cleaning agent is being developed, and certain results have been achieved. For example, the non-toxic cleaning technology developed by the United States, the cleaning principle of the cleaning agent is to replace the chlorofluorocarbon solvent in the original cleaning agent with an alkaline solution, practice has proved that the cleaning technology has a good cleaning effect. In our country, it is also the introduction of some cleaning technology and on this basis made a certain innovation, has achieved good innovation effect, good cleaning effect.

2.Engine hole detection

There are visitation holes on the casing of the turbine of an aeroengine, and the function of these visitation holes is to carry out internal visitation. By using these visitation holes, maintenance staff can detect various parts of the turbine engine, so as to timely discover various problems existing in the blades of the turbine engine, so as to carry out maintenance and treatment in time. Ensure the safe operation of the blades of the engine to avoid adverse effects on the normal operation of the engine. In the engine, the viewing holes reserved in each part have different roles . As far as the viewing hole reserved at the top of the blade is concerned, its function is to detect the wear condition and vulcanization degree of the blade; The main function of the viewing hole reserved in the blade body is to detect the corrosion and damage of the thermal barrier coating. The visiting hole reserved at the root of the blade is used to detect the root of the blade. Since the root of the blade of the engine needs to bear greater pressure, there is a high probability of damage in the process of operation. Therefore, the problem can be found in time by using the visiting hole for detection, and then effective measures can be taken to deal with it, so as to ensure the safety of the generator operation.

For engine maintenance, as more and more problems appear, a variety of new detection and maintenance technologies are gradually applied to engine detection and maintenance work. In order to better meet the needs of inspection and maintenance, the perforating technology has also made corresponding innovations. In the past, the perforating technology mainly used optical prism for detection, but at this stage, with the development of science and technology, electron microscope is used for detection. Through the innovation of perforating technology, the detection can be more clearly carried out. Thus, the effectiveness of detection and the safety of flight are greatly improved.

3. Accurately measure the blade

Aero-engine has a very important impact on the safety of aviation flight, so the maintenance of aero-engine has always been an important maintenance content. In order to ensure flight safety, problems must be found and solved in time, so the detection of engine turbine blades must ensure high accuracy. In the traditional blade detection process, due to the backward detection technology, the caliper Angle gauge is mainly used to measure the blade. In this detection, due to the need for manual measurement, the error is also large and the efficiency is not high . Therefore, in the process of continuous development of science and technology, people have gradually applied coordinate measuring machines to the measurement of turbine blade size, thus effectively improving the efficiency and accuracy of measurement, and ensuring the safety of aviation flight.

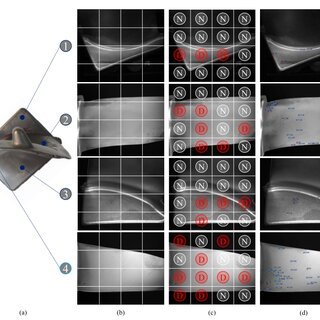

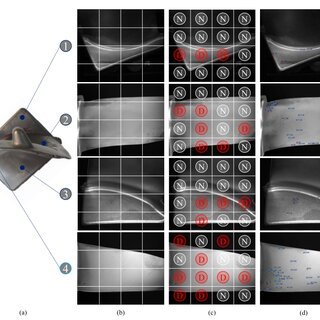

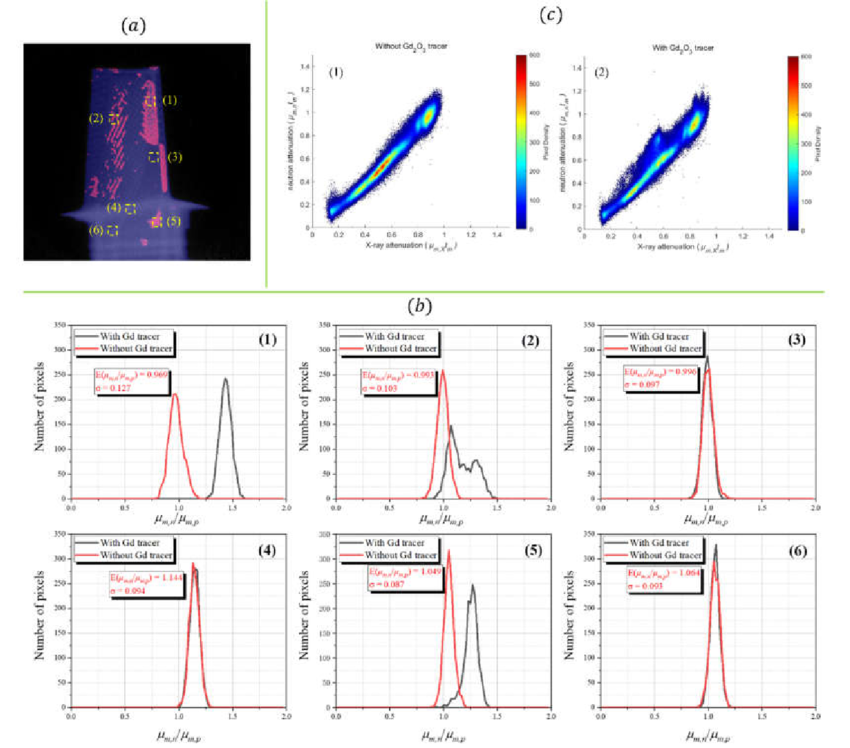

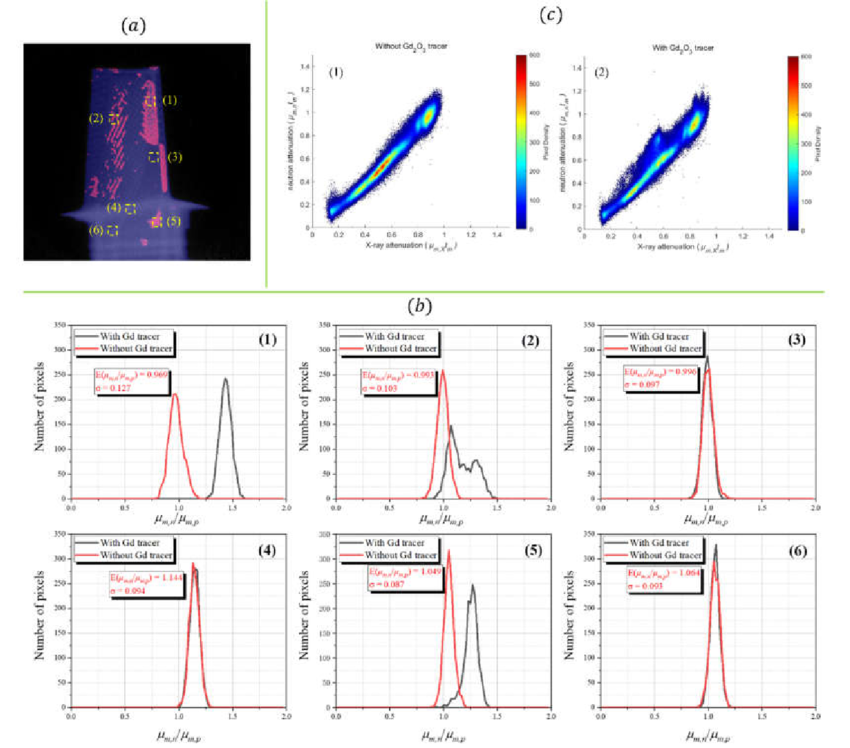

4. Non-destructive testing of turbine blades

For aircraft turbine blades, the main purpose of nondestructive testing is to further test the integrity of the blades. At present, the main methods of non-destructive testing of turbine blades are ultrasonic and CT technology. In the United States, nondestructive testing is the use of ultrasonic equipment for testing, and the detection effect is very good. In the aspect of CT detection technology, it is mainly to detect the cracks and corresponding thickness of turbine blades. In actual operation, the display result is the collected signal source, which shows the complete internal image to people, thus greatly improving the maintenance efficiency . From the point of view of detection technology and means, the current ultrasonic technology and CT technology are the most advanced detection means. Using these two test methods to test turbine blades, the results are more accurate. These two methods have a high degree of automation and are of great significance for the maintenance of turbine blades .

Conclusion

It can be seen from the discussion in this paper that the detection of turbine blades of aero-engines is very important, and the flight safety can be ensured only by ensuring timely discovery and solution of problems. Nowadays, with the continuous development of science and technology, the application of borehole detection technology has been fully realized in the detection process of aero engine turbine blades in our country, but the application of more accurate detection technology is not perfect. Therefore, it is necessary to strengthen the application of advanced detection technology at this stage, so as to better ensure aviation safety.

Thank you for your interest in our company! As a professional gas turbine parts manufacturing company, we will continue to be committed to technological innovation and service improvement, to provide more high-quality solutions for customers around the world.If you have any questions, suggestions or cooperation intentions, we are more than happy to help you. Please contact us in the following ways:

- WhatsAPP:+86 135 4409 5201

- E-mail:peter@turbineblade.net