Turbine blade casting is an advanced processing technology, which has the advantages of high precision, high quality and high efficiency, and has been widely used in energy plants, aircraft engines, automobile manufacturing and other fields. The technology can improve the strength and durability of turbine blades, while also reducing energy consumption and emissions, thereby bringing additional benefits to society and the environment.

1. Design and Modeling:

- Blade design: According to turbine application environment and performance requirements, blade design, including blade shape, size, material, cooling structure, etc.

- 3D modeling: According to the blade design, the 3D model of the blade is established using computer-aided design (CAD) software for subsequent mold making and analysis.

2. Mold manufacturing:

- All the data obtained from measurement, analysis and analysis are systematically collected and sorted out, and a database is established.

- Using computer aided design (CAD) and other software, the three-dimensional model of the product is established, and the simulation analysis is carried out to verify the technical principle and performance of the inference.

3. Material preparation:

- Material selection: According to the application environment and performance requirements of the blade, select the appropriate high-temperature alloy materials, such as nickel-based alloy, cobalt-based alloy, etc.

- Smelting: The raw material is melted to reach a liquid state, and the composition is controlled to ensure that the properties of the material meet the design requirements.

- Pouring: The molten alloy material is poured into the casting mold, and the appropriate filling and cooling is carried out to make the alloy material solidify in the mold.

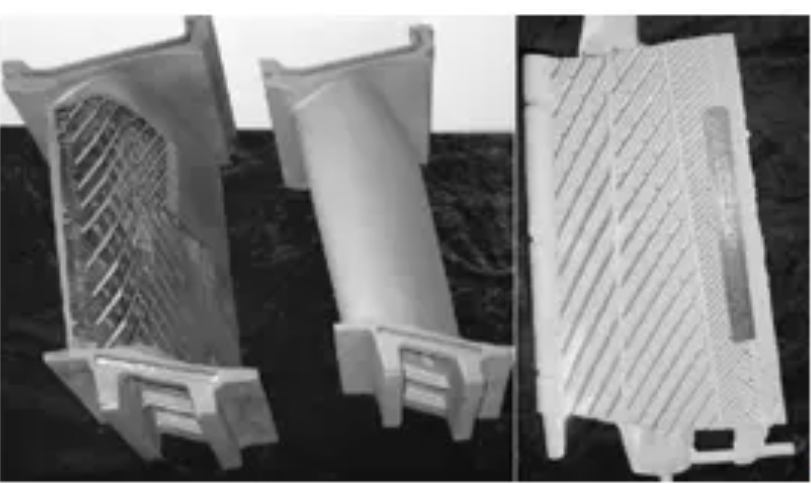

4. Stripping and cleaning:

- Demoulding: After the alloy material solidifies and forms, the casting is removed from the mold.

- Cleaning: The casting is cleaned to remove the residual sand core, burr, oxide, etc., on the surface for subsequent processing.

5. Heat treatment:

- Heat treatment: Heat treatment of castings to eliminate internal stress, refine grains, improve the mechanical properties and service life of castings.

- Aging treatment: aging treatment as needed to improve the hardness, strength and high temperature resistance of the casting.

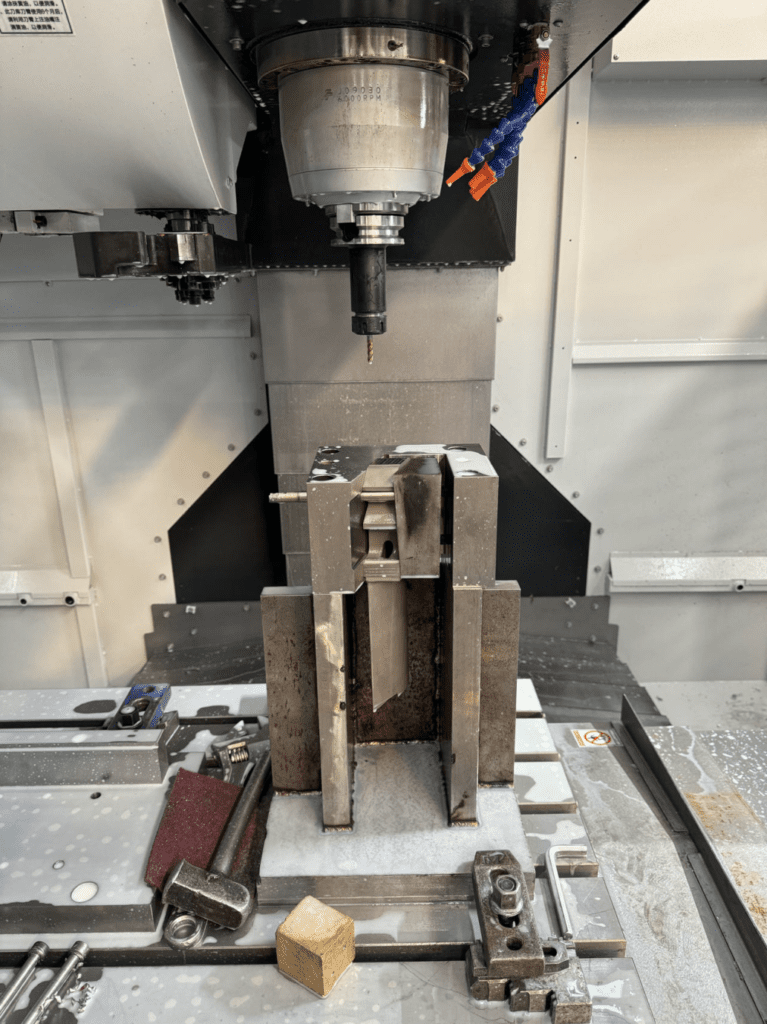

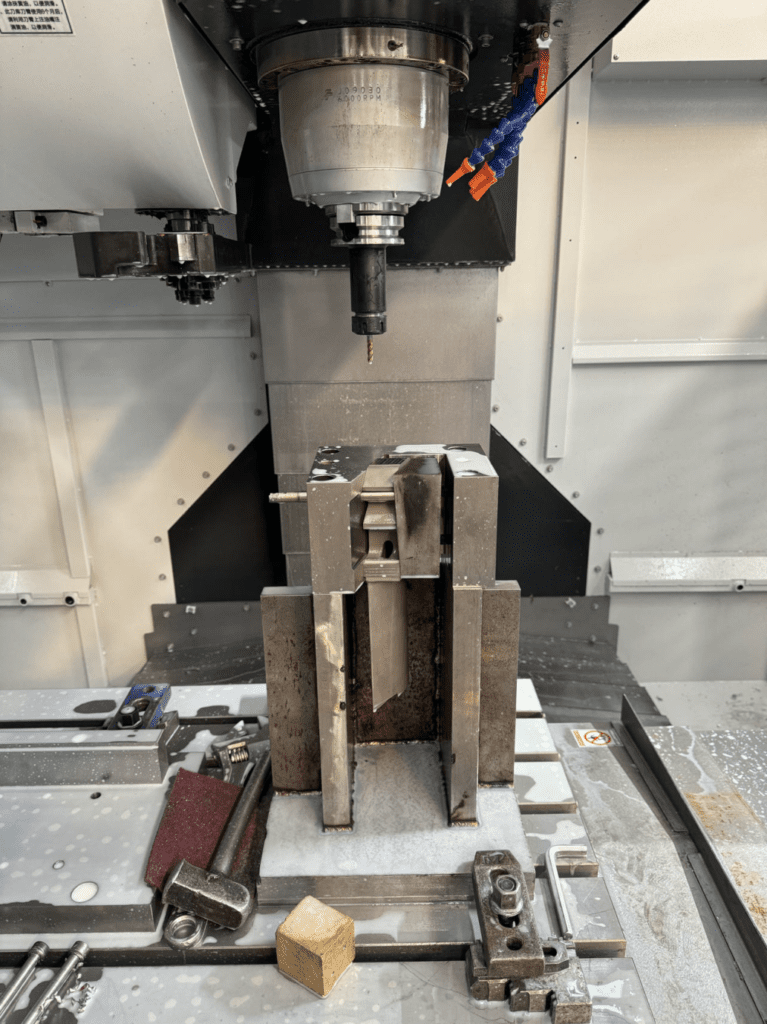

6. Machining:

- Roughing: The casting is roughed, excess material is removed, and dimensional control is carried out to prepare for subsequent finishing.

- Finishing: According to the design requirements of the blade, the casting is finished, such as milling, turning, grinding, etc., in order to achieve the required dimensional accuracy and surface finish.

- Blade root processing: The blade root usually requires special processing processes, such as rolling, spinning, etc., to improve the strength and fatigue properties of the root.

- Blade aerodynamic profile machining: The blade aerodynamic profile needs to be processed using high-precision machine tools and special tools to ensure that the aerodynamic performance of the blade meets the design requirements.

- Blade cooling hole processing: Blade cooling holes need to be processed using specialized processing equipment and processes to ensure that the size, shape and position of the cooling holes meet the design requirements.

7. Surface treatment:

- Shot peening: The blades are treated with shot peening to improve the fatigue strength and corrosion resistance of the blades.

- Coating treatment: According to needs, the blade is coated, such as thermal barrier coating, antioxidant coating, etc., to improve the high temperature resistance and service life of the blade.

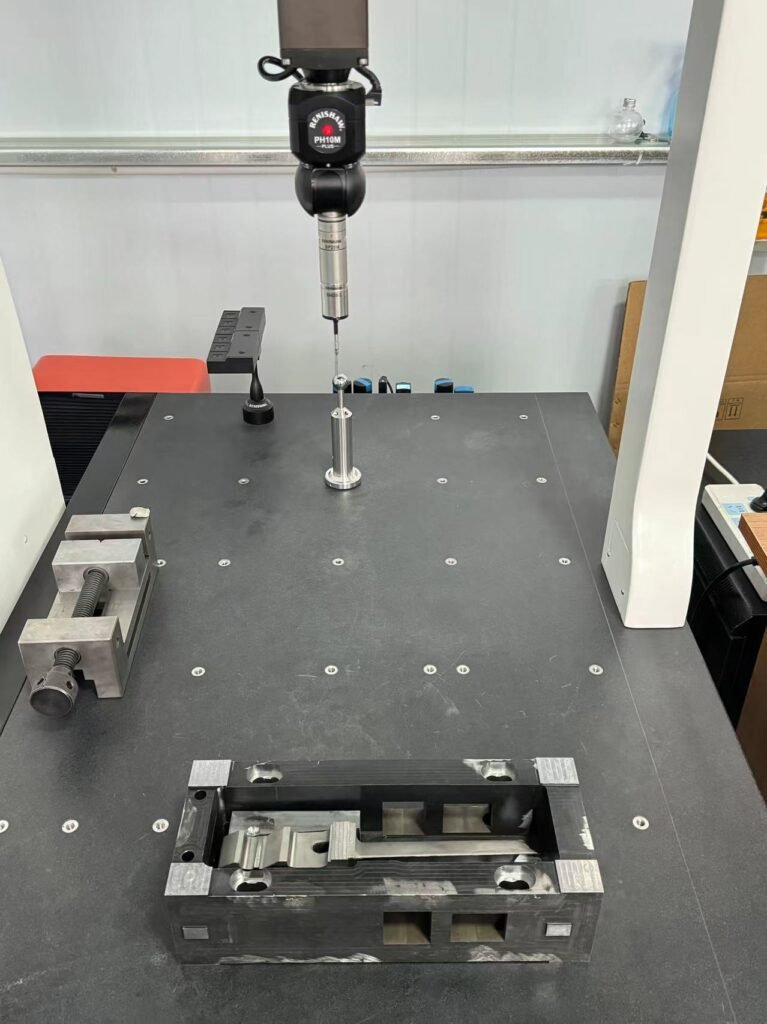

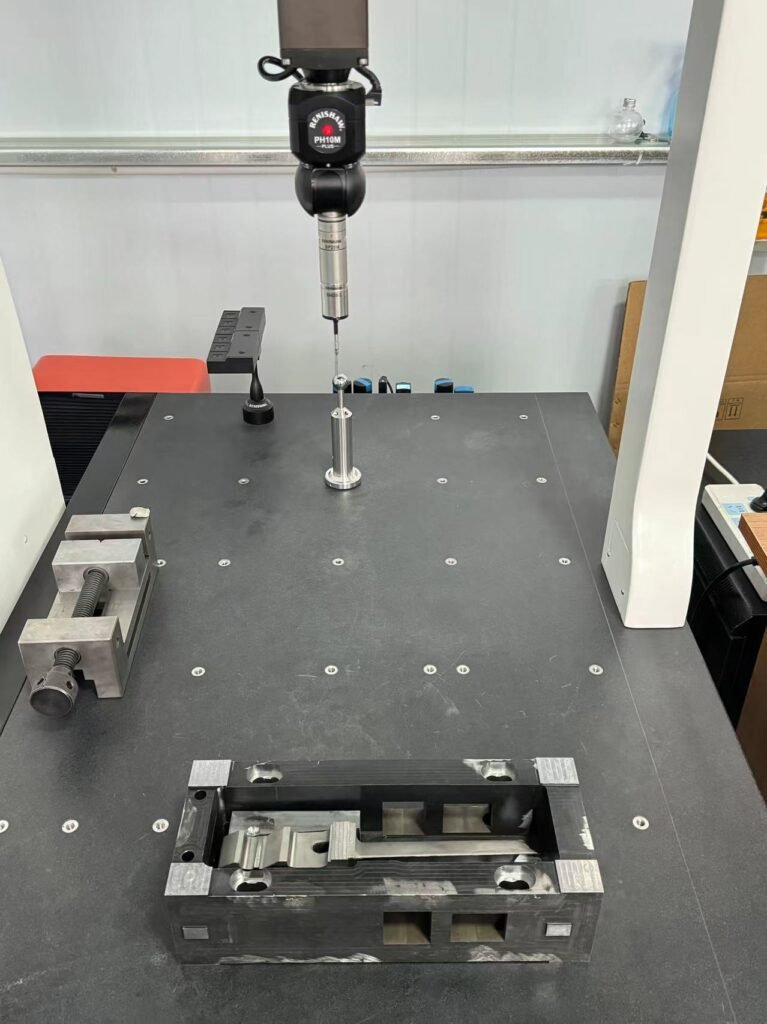

8. Inspection and testing:

- Size inspection: check whether the size of the blade meets the design requirements.

- Appearance inspection: check the surface quality of the blade and check whether there are defects.

- Performance test: test whether the performance of the blade meets the design requirements, such as strength test, hardness test, high temperature fatigue test, high temperature creep test, antioxidant test, aerodynamic performance test, cooling performance test, etc.

Blaze company focuses on the development and manufacture of the core components of aircraft engines, and has advanced superalloy turbine blade casting technology. We use precise molds, rigorous processes and strict quality control to create turbine blades with excellent performance, high temperature resistance and fatigue resistance.