Turbofan engines are important gas turbine-based engines. They power many aircraft and UAVs (drones). Let’s look at how they work, their efficiency, comparison, and main parts.

Main Components of a Turbine Engine

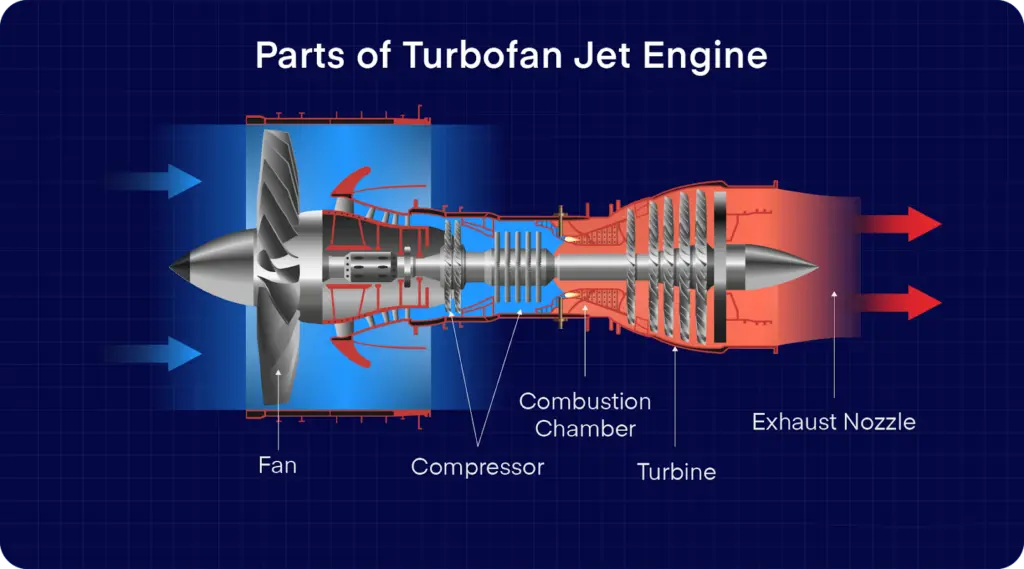

A turbofan engine has several key parts:

- Fan: Helps thrust by speeding up a lot of air.

- Compressor: Raises the pressure and temperature of incoming air.

- Verbrennungskammer: Where air mixes with fuel and ignites.

- Turbine: Takes energy from hot gases to drive the compressor and fan.

- Shaft: Connects rotating parts.

- Nozzle: Speeds up exhaust gases to make thrust.

The fan adds extra thrust. The compressor and turbines keep the engine running. Finally, the nozzle shoots out gases at high speed to move the UAV forward.

How Turbofan Engines Operate

Turbofan engines work much like turboprop engines. Here’s how, step by step:

- Air Intake and Division: A fan pulls air into the engine. The air splits into two paths. One goes into the engine core for burning. The other (bypass air) flows around the core through a duct.

- Compression Process: Air entering the core first goes through a low-pressure compressor (LPC). The LPC raises the air pressure. Then the air moves to a high-pressure compressor (HPC). The HPC compresses the air more, making it very pressurized and hot.

- Combustion and Turbine Action: In the combustor, the compressed air mixes with fuel and ignites on its own. After burning, the high-energy gas flows into the high-pressure turbine (HPT) and then the low-pressure turbine (LPT). These turbines take energy from the gas: some energy drives the compressors and the fan. The rest exits as a fast jet through the exhaust nozzle.

- Thrust Generation: The fast exhaust gases shoot into the air, creating thrust to move the UAV forward. The bypass airflow from the fan joins the exhaust flow, making more thrust overall. The bypass airflow is a bit faster than the free airstream. So, a turbofan gets thrust from both the core and the fan.

Efficiency and Applications of the Turbine Engine

The Efficiency Advantages

Turbofan engines deliver standout efficiency, all thanks to their innovative bypass design. At the heart of this performance is the bypass ratio—the ratio of air that flows around the engine core (bypass air) to the air that enters the core for combustion. Unlike turbojets, which depend entirely on fuel-burning core airflow to generate thrust, turbofans use a large front fan to accelerate massive volumes of bypass air. This bypass air contributes to thrust without consuming extra fuel, meaning turbofans produce more total thrust while using nearly the same amount of fuel as a turbojet’s core.

The efficiency gap widens further with different bypass configurations: high-bypass turbofans (with bypass ratios of 5:1 or higher) come close to matching the fuel efficiency of turboprops, but with the key advantage of operating at much higher subsonic speeds (ideal for commercial flight). Even low-bypass turbofans—designed for military use—outperform traditional turbojets, striking a better balance between thrust output and fuel economy, especially during long cruise phases.

Usage Scenarios

Turbofans’ flexible design makes them indispensable across both civilian and military aviation, with configurations tailored to specific needs. In civil aviation, nearly all commercial airliners (from narrow-body jets like the Boeing 737 to wide-body aircraft like the Airbus A350) rely on high-bypass turbofans. Their combination of fuel efficiency and speed allows airlines to operate long-haul routes economically while keeping flight times competitive.

For military applications, modern fighter jets (such as the F-16 and F-35) use low-bypass turbofans. These engines prioritize compact size and high thrust-to-weight ratios, and crucially, they can integrate afterburners—devices that inject extra fuel into the exhaust to boost speed for dogfights or intercepts. High-bypass turbofans, by contrast, cannot accommodate afterburners due to their large bypass ducts, making low-bypass models the go-to for military fast jets. Beyond fighters, military transport planes also use turbofans, leveraging their efficiency to carry heavy cargo over long distances. This adaptability cements turbofans as the most versatile propulsion choice in modern aviation.

Turbojet vs. Turbofan Engines: A Comparison

- Thrust Generation & Fuel Efficiency: Turbojets rely entirely on compressing, burning, and expelling a small volume of air at supersonic speeds to create thrust—this wastes significant fuel, especially at subsonic speeds. Turbofans, however, use a large front fan to pull in and accelerate a massive amount of “bypass air” around the engine core. This bypass air contributes to thrust without extra fuel, while only a small portion of air enters the core for combustion. The result: turbofans produce more thrust per unit of fuel, with high-bypass models (for airliners) being far more efficient than any turbojet.

- Noise Levels: Turbojets produce intense noise due to their high-velocity exhaust gases. Turbofans are much quieter because the bypass air mixes with and slows the hot core exhaust, reducing turbulence and noise. This is critical for commercial airports, where noise restrictions make turbofans the only viable choice.

- Versatility in Applications: turbojet engines were once used in early fighter jets due to their ability to achieve high speeds, but they are now largely replaced by turbofans in most aircraft. Turbofan engines are widely used in both civil aviation (like commercial airliners) and military aviation (such as modern fighter jets and transport planes).

- Operational Cost: Thanks to better fuel efficiency and lower wear (from reduced core stress), turbofans cut operational costs for airlines and militaries. Turbojets’ high fuel consumption and maintenance needs make them far less economical for regular use.

Conclusion

Turbofan engines dominate aviation today because they are powerful, efficient, and flexible. They use less fuel than turbojets, make less noise, and can be designed for both passenger planes and military jets. This mix of performance and efficiency makes turbofans the best choice for most modern aircraft, and they will likely remain the main type of engine in the skies for years to come.

Take Action Now

Speak to an Expert: peter@turbineblade.net

WhatsApp: +86 135 4409 5201

Why Choose Us

- 20+ years of experience — Over 100,000 blades delivered to 30+ customers worldwide.

- Full capability supply chain – 5-axis CNC, directional solidification furnaces, and industrial CT scanners

- Global Recognition: Working with Siemens, Mitsubish,i and other energy leaders.