The development process of gas turbine includes three main stages: demand analysis and conceptual design, detailed design and simulation, and prototype manufacturing and testing. First, the preliminary design and technical specifications are determined through market demand and technical feasibility studies. Then, detailed engineering design and simulation analysis are carried out to optimize the performance of each component. Finally, the prototype is manufactured and strictly tested to ensure that it meets the design requirements and practical application conditions.

1. Market demand analysis and project start-up

- Demand identification: Through market research, customer feedback or policy requirements, determine the target application scenarios (e.g. power generation, Marine, etc.) of the new gas turbine.

- Performance goal setting: Define the core performance metrics of the gas turbine (power, efficiency, life, emission standards, etc.) and set design goals in conjunction with industry trends.

- Project planning: Establish a project team, define the time node, resource allocation, budget, etc., and start the formal development project.

2. Conceptual design and technical feasibility study

- Thermal cycle design: Based on engineering thermodynamics, determine the thermal cycle scheme of the gas turbine (Brayton cycle, etc.) and estimate the overall efficiency and power output.

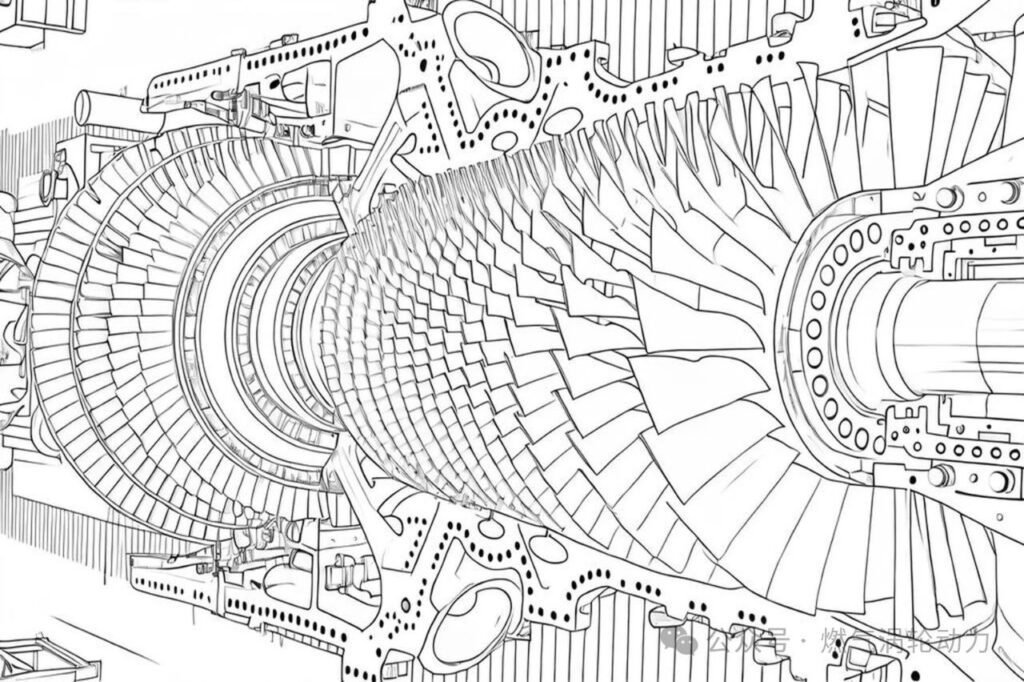

- Aerodynamic design and preliminary CFD simulation: Preliminary aerodynamic design of compressor, combustion chamber, turbine and other key components, and simulation analysis using CFD (computational fluid dynamics) tools to optimize airflow path and performance.

- l Preliminary assessment of materials and manufacturing processes: Select suitable high temperature materials (such as nickel-based superalloys) and manufacturing processes, and conduct a preliminary cost assessment.

- Feasibility study: Multi-dimensional evaluation of the feasibility of the design, including cost, manufacturing process, technical risk, etc.

3. Detailed design phase

(1) Detailed pneumatic design:

- Blade design: Optimise the shape of compressor and turbine blades to ensure optimal hydrodynamic performance.

- Combustion chamber design: Design the combustion chamber structure to ensure efficient combustion of fuel and to meet emission standards.

(2) Structural design and Finite Element Analysis (FEA)

- Stress, vibration and thermal load analysis of critical structures with finite element analysis tools to ensure structural integrity and reliability under extreme conditions.

- Perform dynamic calculation and analysis of rotating components such as rotors and impellers.

(3) Air flow path and cooling design:

- Design cooling channels and thermal protection systems for high-temperature components, such as turbine blades, to optimize cooling and extend component life.

- Material selection and testing: determine the specific composition and heat treatment process of superalloy materials or composite materials to ensure the fatigue and corrosion resistance of materials under high temperature and high stress conditions.

- Carry out material strength, thermal fatigue, creep and other related tests.

4. Prototype manufacturing and test verification

- Prototype manufacture: According to the detailed design scheme, manufacture the prototype of the gas turbine (including core components such as compressor, combustor and turbine). Ensure the accuracy and consistency of each component.

- Bench test: test the thermal efficiency, power output, emission, temperature distribution and other performance of the gas turbine under ignition and load conditions.

- Failure Mode Analysis (FMEA) : Failure mode and effect analysis based on bench test data to identify potential design defects and make improvements.

- Design iteration and optimization: design optimization is carried out based on test data, such as adjusting blade geometry, cooling channel layout, material heat treatment process, etc.

5. Engineering verification and product stereotyping

- Engineering verification tests: Long run tests are conducted in an environment closer to the actual application scenario to verify the stability and reliability of the gas turbine.

- Durability tests: Perform accelerated life tests that simulate long-term operating conditions to assess the durability of gas turbine components.

- Noise and emission testing: Final verification of noise, vibration, emissions (such as NOx, CO) control performance to ensure compliance with relevant regulations and environmental requirements.

- Technical review: According to the test results, carry out multiple rounds of design review to ensure that all performance indicators meet the design requirements and complete the design finalize.

6. Production preparation and mass production

- Production process design: Formulate the manufacturing process for mass production, including precision casting, welding, heat treatment, assembly process, etc., to ensure product consistency and quality stability during mass production.

- Quality control and testing: Establish a strict quality control system, and carry out non-destructive testing, mechanical performance testing and assembly accuracy testing for each gas turbine produced.

- Import automated manufacturing and assembly technology to improve production efficiency and accuracy.

- Supply chain Management: Optimize the supply chain to ensure that materials and components arrive on time and avoid production delays.

7. Maintenance and after-sales support

- Spare parts supply and technical support: Provides long-term spare parts supply, technical upgrade, operation and maintenance support.

- Remote monitoring and fault diagnosis: Through the remote monitoring system, the gas turbine operating status is monitored in real time, and fault diagnosis and preventive maintenance suggestions are provided.

Thank you for your interest in our company! As a professional gas turbine parts manufacturing company, we will continue to be committed to technological innovation and service improvement, to provide more high-quality solutions for customers around the world.If you have any questions, suggestions or cooperation intentions, we are more than happy to help you. Please contact us in the following ways:

- WhatsAPP:+86 135 4409 5201

- E-mail:peter@turbineblade.net