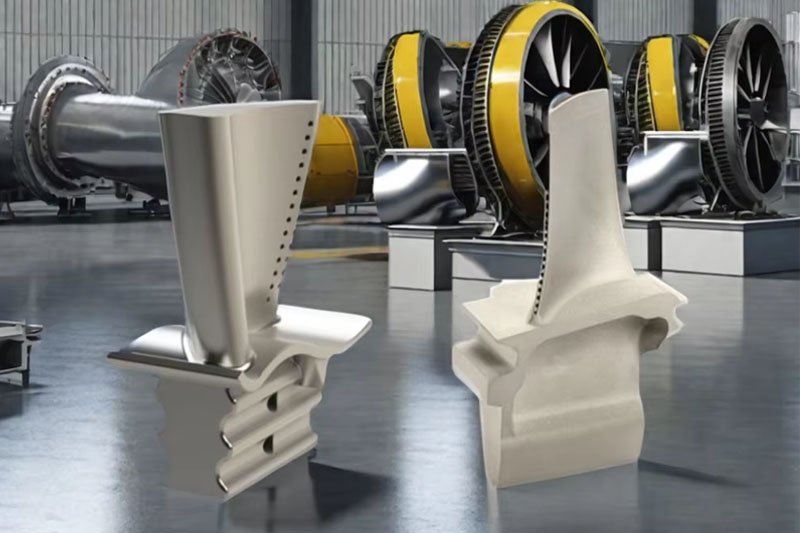

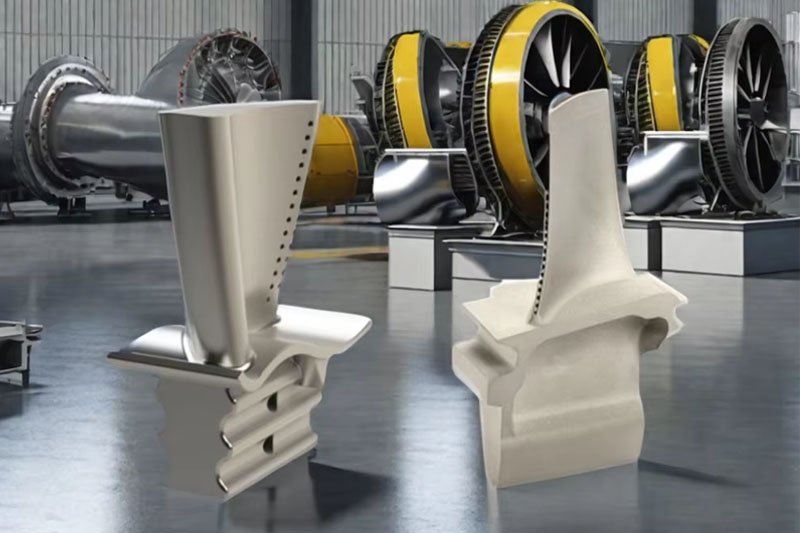

Directional solidification castings have high durability such as high strength, toughness and fatigue resistance, so they are widely used in high-end fields such as aviation, aerospace and energy industries.

Through the directional solidification process, the grain size and shape of the casting can be controlled, thereby improving the precision and surface finish of the casting.

The crystallization direction of the directional solidification casting can be controlled to grow in a certain direction, avoiding defects such as accumulation defects and uneven organization, thereby improving the performance of the casting.

Due to the control of the growth direction of the grains, the grain boundaries of the directional solidification castings can be consistent with the stress direction, thereby improving the high temperature performance of the casting.

Turbine blades made of equiaxed casting are widely used in aircraft engines and gas turbines. These blades have good high temperature strength and corrosion resistance, and are suitable for high temperature and high pressure parts of turbines.

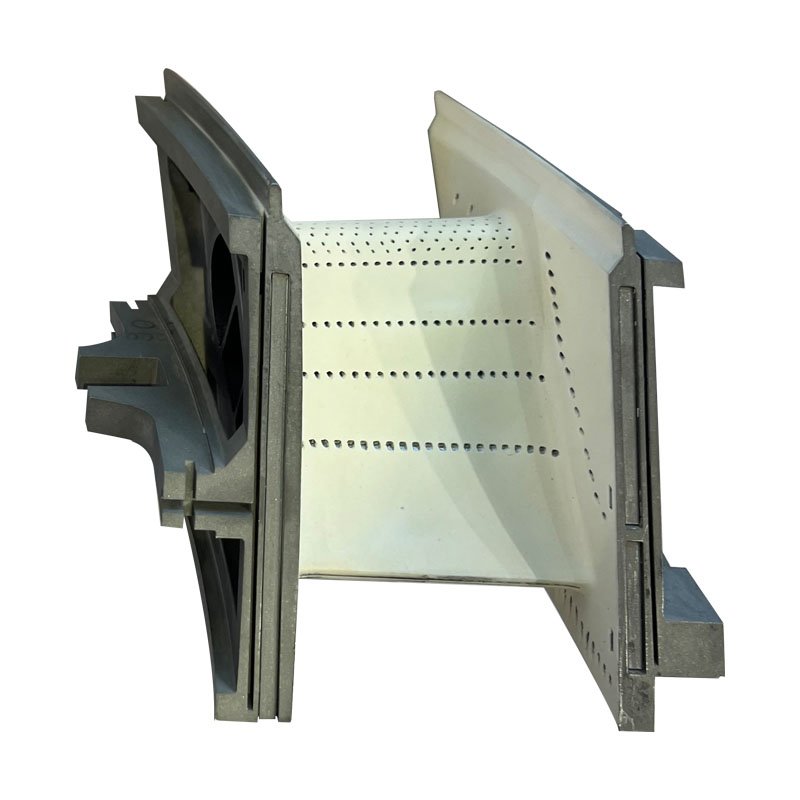

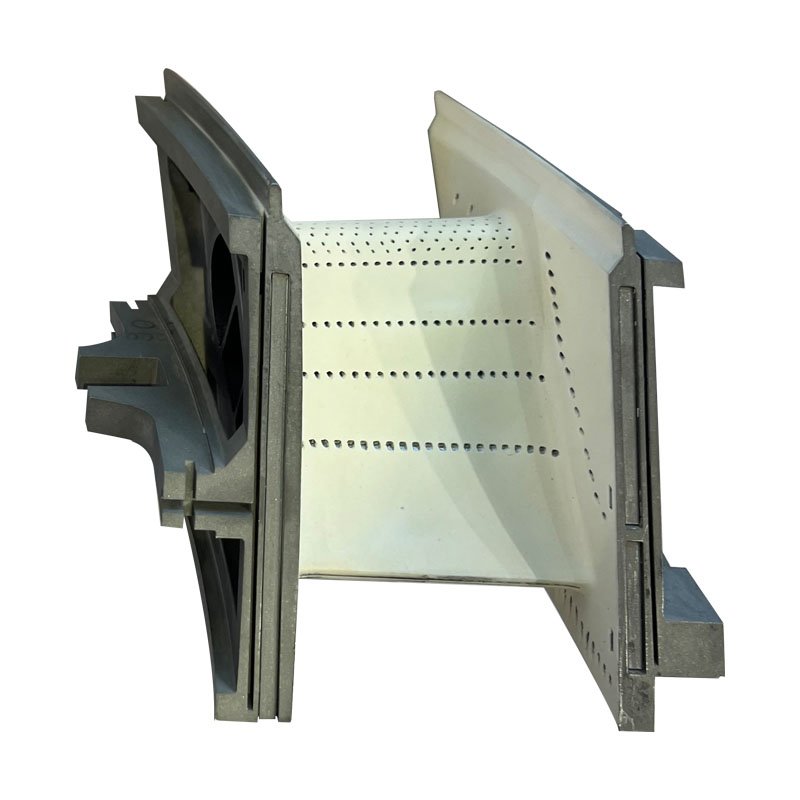

Turbine disks are important components that support turbine blades and transmit power. The equiaxed casting process can produce turbine disks with good mechanical properties and durability, which are suitable for various turbine equipment.

Engine turbine accessories also include several key components, each of which plays a vital role in the high temperature, high pressure and high speed environment of the engine.

Part numbers alone are not sufficient to ensure performance.

To guarantee precision and compatibility, please provide:

Drawings or used samples for reverse engineering.