Turbine blades are the backbone of modern power generation, converting thermal energy into mechanical energy with exceptional efficiency. In a world where performance and reliability are non-negotiable, choosing the right material is crucial. Among the many options, Inconel 625 stands out as an unparalleled choice, offering a unique blend of strength, corrosion resistance, and high-temperature stability that makes it ideal for the most demanding applications.

The Superiority of Inconel 625 in Turbine Blade Construction

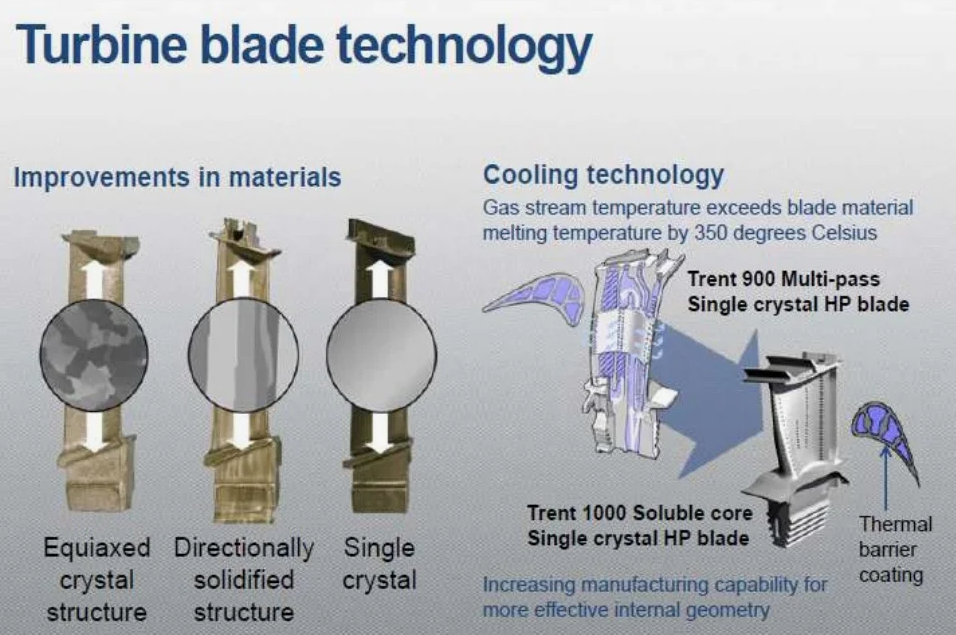

Inconel 625, a nickel-chromium-based superalloy, has established itself as one of the best materials for manufacturing turbine blades due to its remarkable properties. This superalloy retains its strength at extremely high temperatures, making it perfect for environments where conventional materials would fail. Its ability to withstand temperatures up to 1000°C (1832°F) without significant loss of tensile strength or creep resistance is a key factor in its selection for turbine blade fabrication.

Moreover, Inconel 625’s excellent resistance to oxidation and corrosion, even in the presence of seawater and other aggressive chemicals, ensures that turbine blades can operate efficiently over long periods, reducing maintenance costs and downtime. This property is particularly important in marine and offshore wind turbine applications, where exposure to saltwater and harsh weather conditions is inevitable.

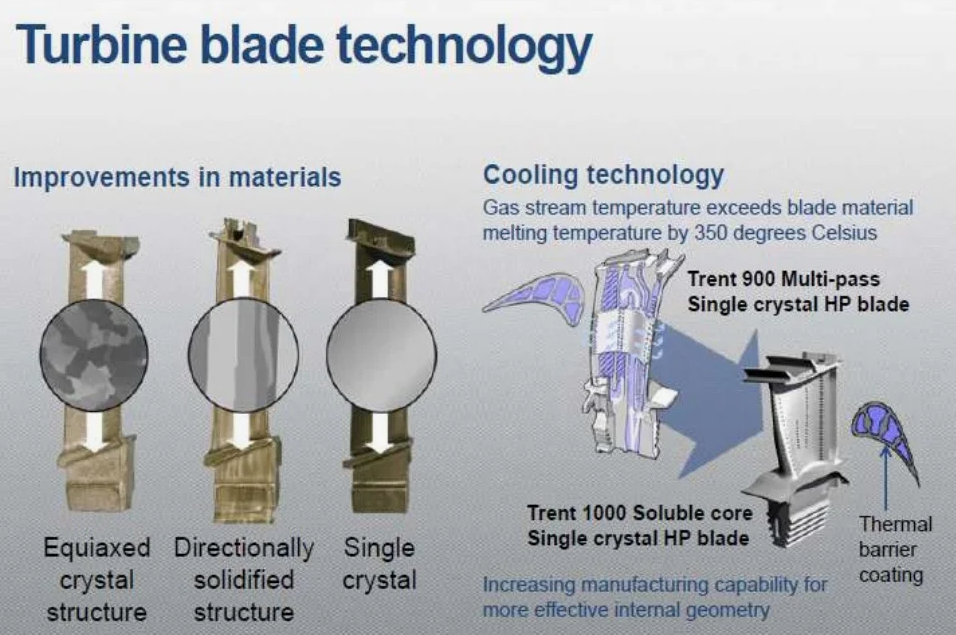

Advanced Manufacturing Techniques for Optimal Performance

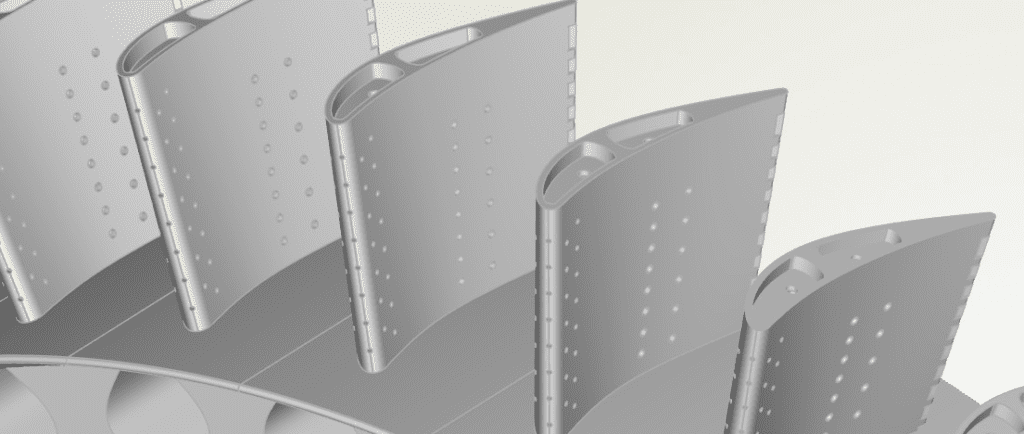

The production of Inconel 625 turbine blades involves cutting-edge manufacturing processes designed to optimize their aerodynamic profile while ensuring structural integrity. Precision casting, advanced machining, and sophisticated heat treatment methods are employed to create blades that not only meet but exceed industry standards. By leveraging state-of-the-art technology, we can produce turbine blades that offer superior performance, enhanced durability, and increased operational lifespan.

Reverse Engineering Capabilities: Tailored Solutions for Every Need

At BLAZE, we understand that every application is unique, and sometimes off-the-shelf solutions are not enough. Our team excels in reverse engineering, allowing us to replicate and improve upon existing designs. Whether you need to replace a specific component, enhance the performance of an existing turbine, or develop a new design, our reverse engineering capabilities ensure that we can provide a tailored solution that meets your exact requirements.

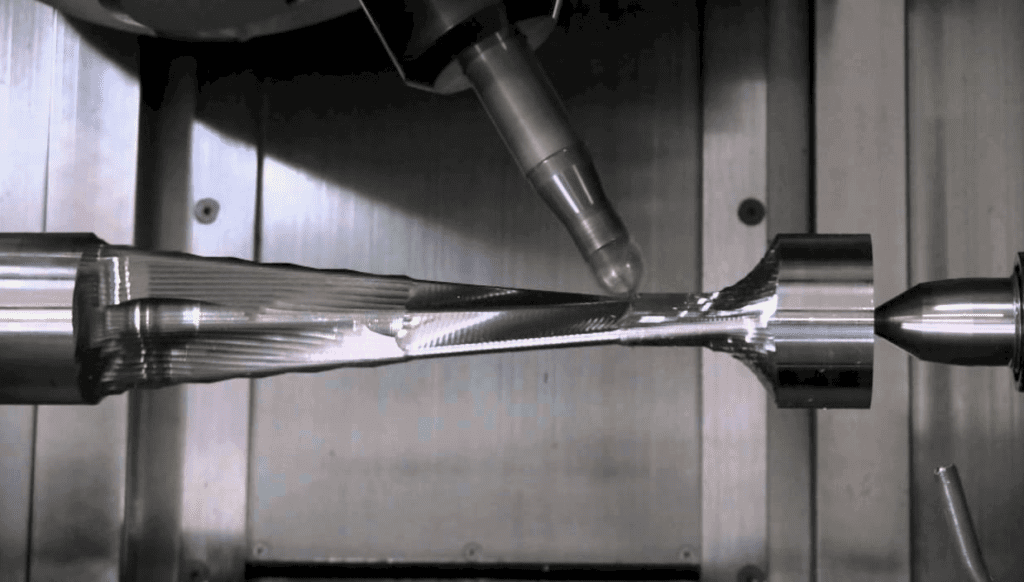

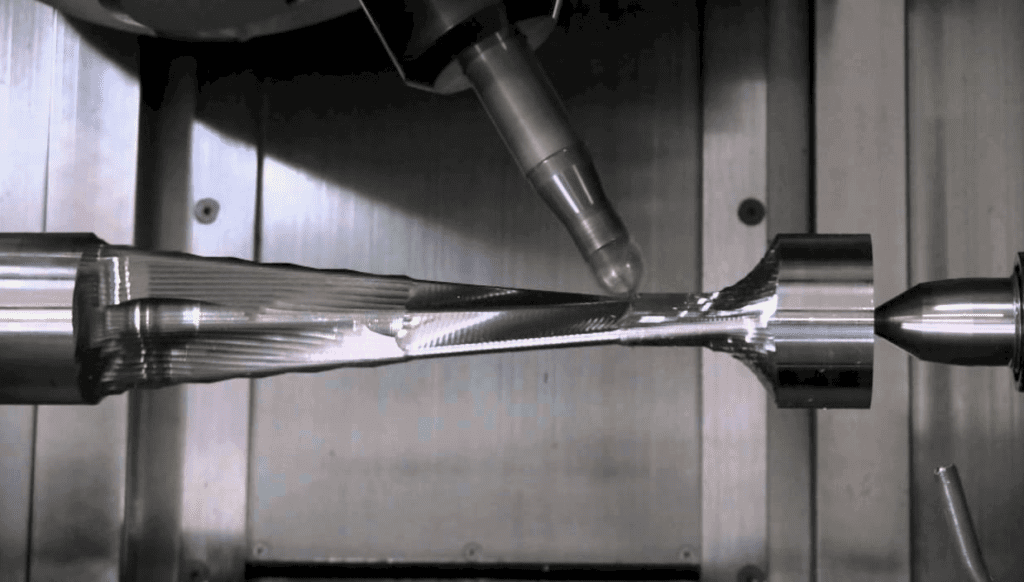

Our reverse engineering process begins with a detailed analysis of the original part, using advanced 3D scanning and measurement techniques. We then use this data to create a digital model, which is meticulously refined to incorporate any desired improvements. This could include optimizing the blade’s aerodynamics, enhancing its material properties, or improving its overall durability. Once the design is finalized, we employ precision manufacturing techniques to produce the new component, ensuring it matches or exceeds the original in terms of quality and performance.

Environmental and Economic Benefits

- By utilizing Inconel 625 for turbine blades, we contribute to more sustainable energy solutions. The longevity and reduced maintenance requirements of these blades translate into lower environmental impact, as fewer resources are needed for repairs and replacements. Additionally, the improved efficiency of turbines equipped with Inconel 625 blades leads to greater energy output, supporting the transition towards cleaner, more reliable power generation systems.

- Economically, the extended lifespan and reduced downtime result in significant cost savings for operators. Inconel 625 blades require less frequent maintenance, which means lower operational costs and higher availability of the turbine. This translates into a better return on investment and a more stable and predictable energy supply. Furthermore, the high performance and reliability of Inconel 625 blades help to reduce the risk of unexpected failures, ensuring that power generation remains consistent and reliable.

Case Studies and Industry Recognition

Our commitment to excellence has been recognized through numerous successful projects and industry awards. For example, in a recent project, we worked with a leading aerospace company to develop a new set of turbine blades for a high-performance jet engine. Through our reverse engineering and optimization process, we were able to increase the blade’s efficiency by 15%, resulting in a 10% reduction in fuel consumption. This not only improved the engine’s performance but also significantly reduced its environmental footprint.

Our Commitment to Excellence

At BLAZE, we are dedicated to providing our clients with the highest quality turbine blades, crafted from Inconel 625. Our team of experts works closely with you to understand your specific needs and deliver custom solutions that enhance the performance of your operations. With a strong focus on innovation, quality, and customer satisfaction, we strive to be your trusted partner in achieving your goals.

Get in Touch Today

Ready to take the next step towards enhancing the efficiency and reliability of your turbine systems? Contact us today to learn more about how our Inconel 625 turbine blades and our reverse engineering capabilities can make a difference. Our knowledgeable staff is here to answer any questions and provide detailed information on our products and services. Together, we can build a future powered by excellence.