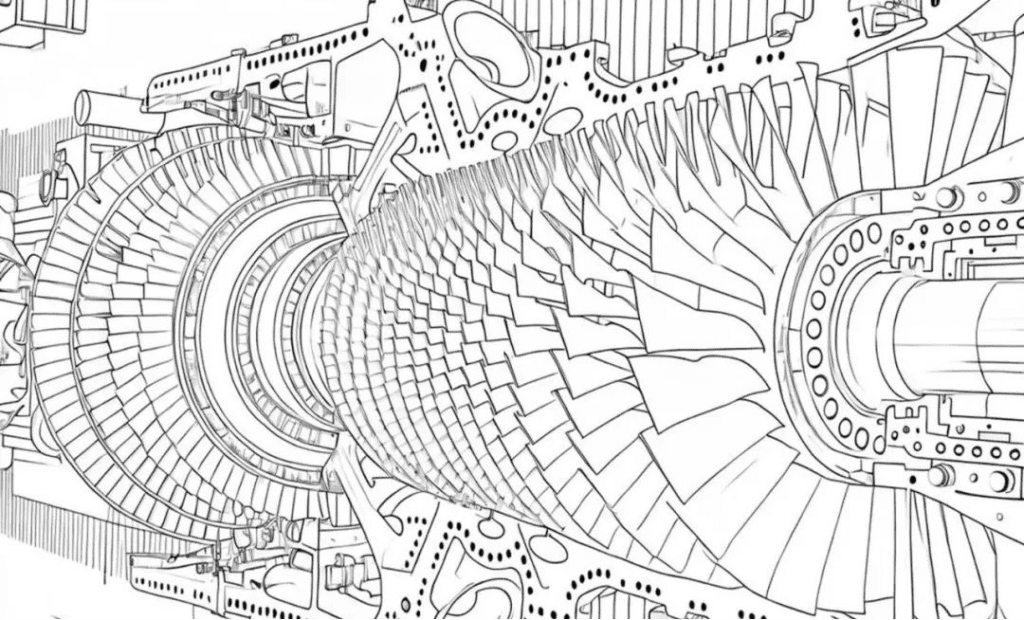

In the demanding world of power generation and industrial applications, gas turbines must operate with unparalleled reliability and efficiency. Ensuring their structural integrity is crucial to achieving long-term performance and minimizing downtime. This article explores the key structural detail design principles that are essential for enhancing the reliability of gas turbines. We will delve into advanced material selection, thermal management, stress analysis, and innovative manufacturing techniques, all of which play a critical role in creating robust and durable turbine designs.

1.Equal Strength Design

Section Size and Stress Variation: Optimize section sizes based on stress distribution to ensure uniform stress distribution and prevent localized high stress, achieving equal strength design.

2.Stability of Supporting Structures

Sufficient Stiffness: Support structures should have enough stiffness to maintain shape and dimensions throughout the operating life, preventing deformation and performance degradation or failure.

3.Stiffness Matching of Connected Parts

- Consistent Stiffness: Coordinate stiffness between connected parts and components to avoid stress concentration caused by stiffness mismatch and part failure.

- Reasonable Force Transmission Path: Ensure reasonable force transmission paths and avoid abrupt changes in local stiffness and stress concentration caused by eccentric loads.

4.Transition Design for Section Abrupt Changes

Transition Zones and Rounded Corners: Design sufficient transition zones and rounded corners in areas where shaft and disk sections change to reduce stress concentration and prevent fatigue crack initiation and propagation.

5.Thermal Deformation Allowance

High-Temperature Structure Design: Structures influenced by high temperatures should have adequate thermal deformation allowance to permit material expansion and prevent cracking or damage caused by impeded thermal expansion.

6.Effective Cooling Design

Uniform Temperature Distribution: Design cooling channels and airflow paths to ensure uniform temperature distribution in components and prevent localized overheating, extending component life.

7.Avoid Composite Stress Concentrations

Multiple Stress Concentrators: Avoid combining multiple stress concentrators such as holes, sharp corners, and discontinuities in the same area, as overlapping stress concentrations can lead to structural failure.

8.Structural Treatment of High-Stress Areas

Avoid Holes and Threads: Minimize holes, threads, or other processing that can induce stress concentration in high-stress areas of components. Utilize reinforcement designs when necessary.

9.Anti-Vibration Design

- Natural Frequency and Exciting Frequency Margin: Ensure that the structural natural frequency is sufficiently far from the operating frequency of the gas turbine to avoid resonance. This can be achieved by adjusting component mass, stiffness, or geometry.

- Vibration Damping Structures: Reduce vibration transmission by adding damping materials or using appropriate support designs.

- Dynamic Load Analysis: Conduct detailed dynamic analysis during the design phase to consider all possible operating conditions and their structural impact, ensuring stable operation under various load changes.

- Vibration Fatigue Assessment: Conduct vibration fatigue assessment to predict fatigue life under prolonged vibration and optimize the design based on the assessment results.

- Vibration Dampers and Isolators: Use vibration dampers, isolators, or other energy absorption devices in critical areas to minimize vibration impact.

- Rotating Part Balance: Ensure balance of rotating components through precise balancing to control force and moment equilibrium, preventing vibration and additional stress caused by imbalance.

10.Fatigue Life Design

Stress Concentration and Fatigue Assessment: Consider the working cycle and load variations of the gas turbine. Avoid stress concentrations and utilize low-cycle and high-cycle fatigue life assessment methods to ensure reliable operation within the expected service life.

11.Surface Quality Control

Eliminate Surface Defects: Ensure deburring and rounding of sharp edges on component surfaces and achieve appropriate surface roughness requirements to reduce stress concentration and fatigue crack risk, particularly in high-stress areas.

12.Creep Resistance of Materials

High-Temperature Material Selection: Due to prolonged operation at high temperatures, gas turbine materials must have excellent creep resistance. Commonly used alloys are high-temperature and creep-resistant.

13.Fail-Safe Design

Error Prevention Mechanisms: Incorporate fail-safe mechanisms in the design, such as unique mating and installation methods for components, to ensure minimal errors during assembly or maintenance, enhancing system reliability and maintainability.

This detailed list of principles, with a focus on key aspects like stress management, thermal considerations, and vibration control, will contribute to a more robust and reliable gas turbine design.

Contact Us

If you have a strong interest in our products, do not hesitate to contact us immediately. Our professional team will be happy to serve you, answer your every question, provide you with detailed product information and personalized solutions.