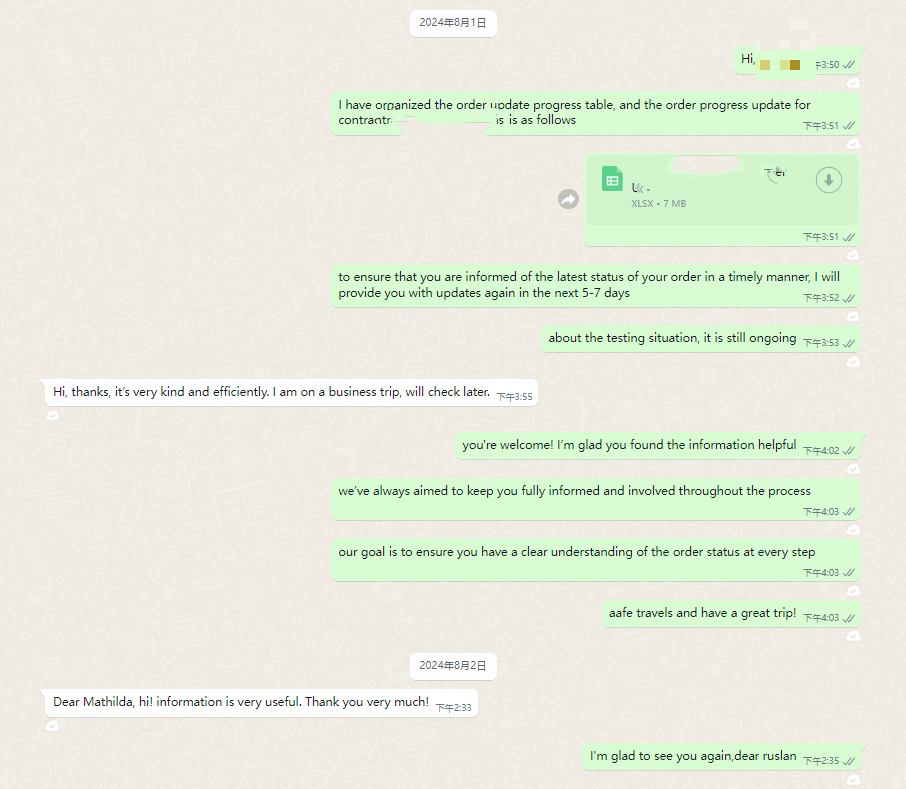

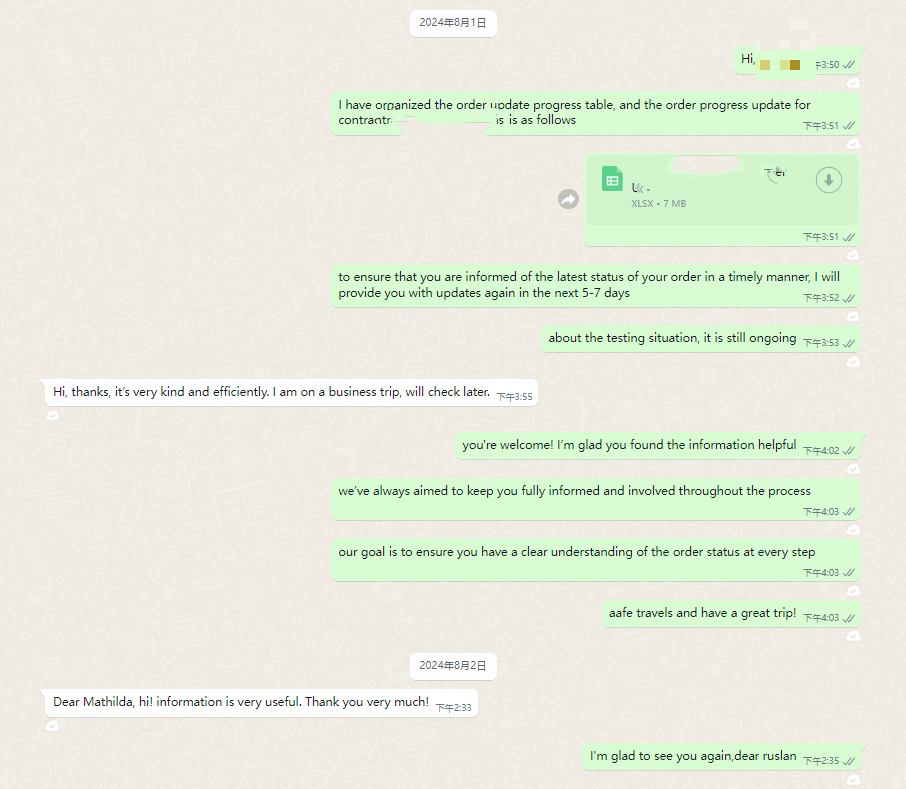

In the gas turbine industry, key components for performance excellence and reliability are at the heart of customer concern. As a company focused on the export of high-quality gas turbine components, we understand the importance of innovative technologies and quality materials to meet these needs. Recently, we worked with a Russian energy company to successfully supply them with segment products produced using the Equiaxed Crystal Casting process. This success story not only demonstrates our professionalism in the manufacturing process, but also demonstrates our choice and application of high-quality materials.

1.Project background

Our partner is a world-renowned energy solutions provider dedicated to the manufacture of power generation equipment with high efficiency and low emissions. As market demand and technology have advanced, they have been looking for key component suppliers that can enhance the performance of their latest generation gas turbines. It is in this context that the two sides have begun in-depth cooperation and exchanges.

2.Material selection

In order to meet the requirements of high temperature and high pressure working environment inside the gas turbine, we choose nickel-based superalloy as the raw material. These alloys are known for their excellent high temperature strength, creep resistance and good resistance to oxidative corrosion. Strict quality control processes ensure that each batch of raw materials meets the highest standards, thus laying a solid foundation for subsequent manufacturing processes.

3. Production process

(1) Smelting preparation:

- Raw material screening: High purity nickel-based superalloy raw materials are selected and detailed chemical composition analysis is carried out to ensure that they comply with specific technical specifications.

- Pretreatment: Clean raw materials to remove surface impurities and oxide layers to ensure purity before melting.

- Smelting: The raw material is melted using a vacuum induction melting furnace (VIM) or an electric arc melting furnace (VAR). The gas inclusion can be effectively removed under vacuum environment to ensure the purity and uniformity of the alloy.

(2) Directional solidification:

- Mold preparation: Design and prepare a mold specially used for equiaxed crystal casting, and the cavity shape of the mold needs to accurately correspond to the geometry of the final product.

- Pouring: Molten metal is poured into a preheated mold, and the bottom of the mold remains cool, creating a temperature gradient from top to bottom.

- Controlled temperature cooling: By precisely controlling the cooling rate, the liquid metal gradually solidifies from the bottom. In this process, the metal crystallizes into fine and randomly oriented equiaxed grains, avoiding the formation of columnar or dendrite structures.

- Completion of solidification: When the whole casting is completely solidified, appropriate heat preservation treatment is carried out to release the internal stress and prevent cracks.

(3) Heat treatment:

- Solution treatment: The initially formed segment is heated to a certain temperature and held for a period of time, so that the second phase of the alloy is dissolved in the matrix, and then quickly cooled to obtain a uniform supersaturated solid solution.

- Age hardening: After solid solution treatment, the segment is insulated for a long time at a lower temperature, which promotes the precipitation of the strengthened phase and further improves the strength and toughness of the material.

(4) Machining and surface treatment:

- Roughing: The use of CNC machine tools for preliminary cutting of castings to remove excess rough edges and uneven parts.

- Finishing: The segment is finely processed by precision grinding machines, milling machines and other equipment to ensure that each dimension and shape tolerance meet the design requirements.

- surface treatment: Polished, sandblasted or other surface strengthening treatments, such as coating or nitriding, are applied to the finished surface as needed to improve wear and corrosion resistance.

(5) Quality inspection:

- Non-destructive testing: X-ray testing, ultrasonic testing, magnetic particle testing and other non-destructive testing means are used to check whether there are pores, cracks and other defects inside the casting.

- Dimensional accuracy testing: Using the coordinate measuring machine (CMM) and other precision measuring tools, the size of each segment is measured in detail to ensure that it meets the requirements of the drawing.

- Mechanical properties test: Take samples for tensile test, hardness test, etc., to verify whether the mechanical properties of the material are up to standard.

- Final inspection: A comprehensive visual inspection and functional test is carried out to confirm that all finished products meet the specific requirements of the customer and industry standards.

4.Presentation

These segments produced by equiaxed crystal casting process were installed in the customer’s new gas turbine and have been verified in practical operation for a long time. The results show that these components not only meet the expected technical specifications, but also perform well under extreme operating conditions, significantly improving the efficiency and reliability of the entire system. In addition, due to the superior performance of the material, the maintenance frequency is reduced, the service life is extended, and considerable economic benefits are brought to the customer.

Thank you for your interest in our company! As a professional gas turbine parts manufacturing company, we will continue to be committed to technological innovation and service improvement, to provide more high-quality solutions for customers around the world.If you have any questions, suggestions or cooperation intentions, we are more than happy to help you. Please contact us in the following ways:

- WhatsAPP:+86 135 4409 5201

- E-mail:peter@turbineblade.net