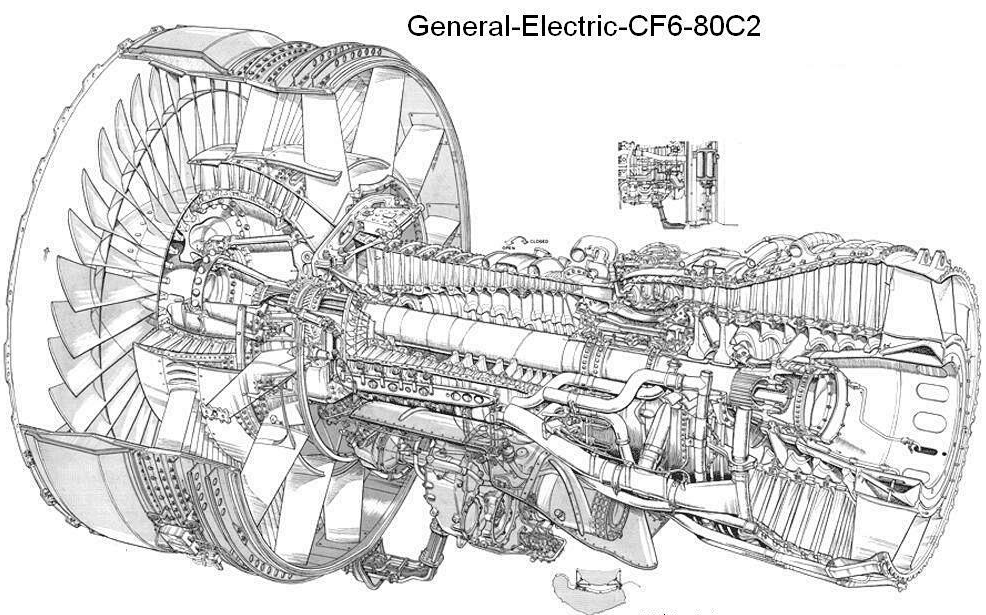

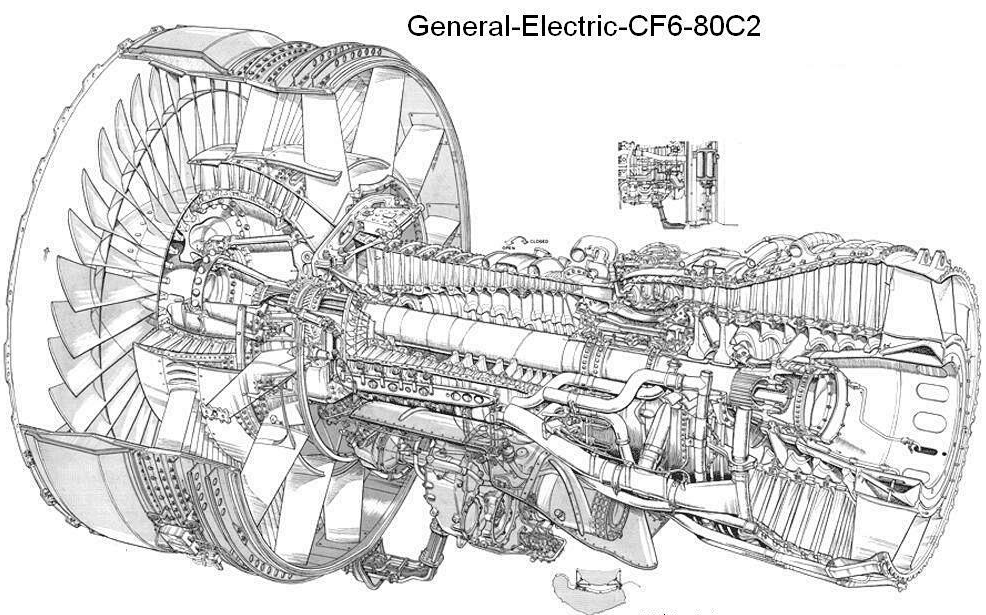

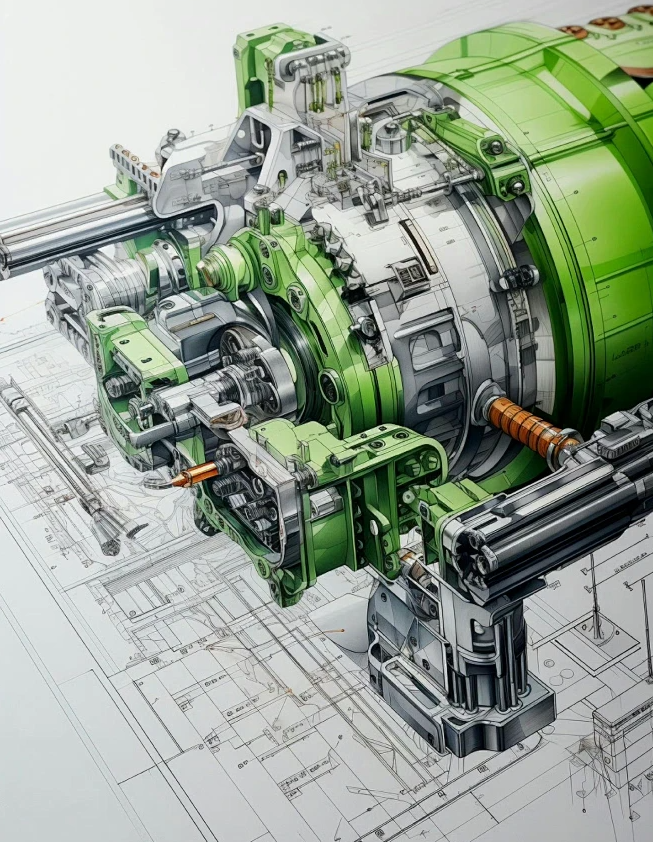

Gas turbines, as highly efficient and flexible power units, are widely used in power generation, marine propulsion, and industrial drive applications. However, to ensure their reliability and performance under various operating conditions, designers must consider a range of complex scenarios. This article will explore the key operating conditions that need to be carefully considered during the design process of gas turbines, including start-up, normal operation, environmental factors, transient conditions, extreme conditions, and fault handling.

1. Start-Up Conditions

- Cold Start: When starting from a completely cold state, thermal stress and thermal expansion become major issues due to temperature differences between components. The sudden introduction of hot gases into a cold turbine can lead to significant thermal gradients, which may cause material fatigue and structural damage. Additionally, low temperatures can increase material brittleness, so special attention must be paid to vibration control during start-up to prevent structural damage. Advanced materials and coatings, as well as gradual heating procedures, are often employed to mitigate these effects.

- Hot Start: If a gas turbine is restarted before it has fully cooled down, rapid heating cycles may impact component life. In this scenario, the design should focus on minimizing the effects of thermal shock on materials and ensuring operational stability. Special considerations include optimizing the cooling systems and using materials with high thermal fatigue resistance. Hot starts require careful management of the turbine’s thermal profile to avoid excessive thermal cycling, which can reduce the lifespan of critical components like blades and vanes.

2. Normal Operating Conditions

- Design Point Condition: This refers to the standard condition where the gas turbine operates at its rated power output. At this point, the emphasis is on improving thermal efficiency, reducing fuel consumption, and maintaining safe operating temperatures for high-temperature components like turbine blades. Designers use advanced computational fluid dynamics (CFD) and finite element analysis (FEA) to optimize the aerodynamic and thermal performance of the turbine. Materials such as nickel-based superalloys and ceramic matrix composites are often used to withstand the extreme temperatures and stresses.

- Part Load Condition: As load varies, the gas turbine may operate below its rated power. Although efficiency decreases, optimizing combustion processes and other system parameters can still achieve better economics. Part-load operation requires careful tuning of the combustion system to maintain stable and efficient combustion, even at lower power outputs. Techniques such as variable guide vanes and bleed air systems are used to manage the airflow and pressure ratios, ensuring optimal performance across a wide range of operating points.

- Full Load Condition: During maximum load operation, all components work under extreme conditions. Maintaining overall system stability and the long-term durability of each part is crucial. At full load, the turbine experiences peak temperatures and pressures, and the design must ensure that all components, especially the hot section, can withstand these conditions without degradation. Advanced cooling techniques, such as film cooling and internal cooling, are essential to protect the turbine blades and vanes.

3. Environmental Conditions

- Inlet Temperature and Humidity: Variations in ambient air temperature and moisture content directly affect the quality of air entering the compressor, which in turn impacts overall performance. In hot or humid environments, specific measures are required to compensate for these adverse effects. For example, inlet air cooling systems can be used to lower the temperature and increase the density of the incoming air, thereby improving the turbine’s performance. Additionally, anti-icing systems may be necessary to prevent ice formation in cold and humid conditions.

- Altitude: As the installation location’s altitude increases, the oxygen content in the air decreases, reducing the engine’s power output. Adjustments are necessary to maintain optimal efficiency at higher altitudes. At high elevations, the reduced air density can significantly impact the compressor’s performance, and the design must account for this by adjusting the blade profiles and compressor stages. Derating the turbine or using intercooling systems can help mitigate the effects of high-altitude operation.

4. Transient Conditions

- Acceleration/Deceleration Conditions: During load changes, such as fluctuations in grid demand, the gas turbine experiences rapid speed adjustments. The additional mechanical stresses require the structure to have sufficient strength; also, attention must be paid to localized overheating. Advanced control systems and robust mechanical designs are essential to manage these transient conditions. The control system must be able to respond quickly and accurately to changes in load, while the mechanical design must be capable of withstanding the resulting stresses and vibrations.

- Load Sudden Changes: In response to sudden increases or decreases in power demand, the control system must be sufficiently sensitive and responsive to ensure smooth transitions without damaging the equipment. Rapid load changes can cause significant thermal and mechanical stresses, and the design must include features such as surge protection, overspeed governors, and fast-acting valves to manage these events. The control system should also be designed to minimize the impact of load changes on the turbine’s overall performance and longevity.

5. Extreme Conditions

- Over-Temperature Conditions: Although modern gas turbines are equipped with advanced cooling technologies, local areas may exceed normal operating temperatures under certain abnormal circumstances (e.g., poor heat dissipation). Prevention and response to such events are critical for safe operation. Over-temperature conditions can lead to material degradation, coating spallation, and even catastrophic failure. Designers must incorporate safety margins and fail-safes, such as temperature sensors and automatic shutdown mechanisms, to protect the turbine in case of over-temperature events.

- Over-Pressure Conditions: Similarly, in cases of unexpected pressure surges, all pressure vessels and related components must be able to withstand such challenges without failure. Over-pressure conditions can result from various factors, including blockages, malfunctions, or external events. The design must include robust pressure relief systems, such as burst discs and relief valves, to safely vent excess pressure and prevent structural damage. Additionally, the materials and structures must be designed to handle the maximum possible pressures, with appropriate safety factors and regular inspections to ensure integrity.

6. Fault Conditions

Emergency Situations Handling: Whether it’s a fuel supply interruption, power failure, or other emergency, the gas turbine must have robust emergency shutdown mechanisms to safely stop the unit within the shortest time possible, preventing further incidents. Emergency shutdown procedures must be carefully designed and tested to ensure they can be executed quickly and reliably. This includes redundant control systems, fail-safe actuators, and clear protocols for operators to follow. Regular training and drills are also essential to ensure that personnel are prepared to handle emergency situations effectively.

In summary, gas turbine design is a multidisciplinary process involving fluid dynamics, thermodynamics, materials science, and more. Only by comprehensively considering these various complex conditions and through precise calculations and experimental validation can high-performance and highly reliable products be developed. The integration of advanced materials, sophisticated control systems, and robust mechanical designs is essential to ensure that gas turbines can operate safely and efficiently under a wide range of operating conditions.

Contact Us

If you have a strong interest in our products, do not hesitate to contact us immediately. Our professional team will be happy to serve you, answer your every question, provide you with detailed product information and personalized solutions.