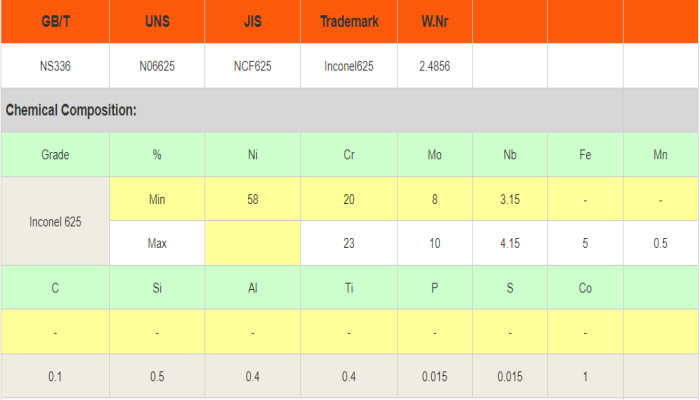

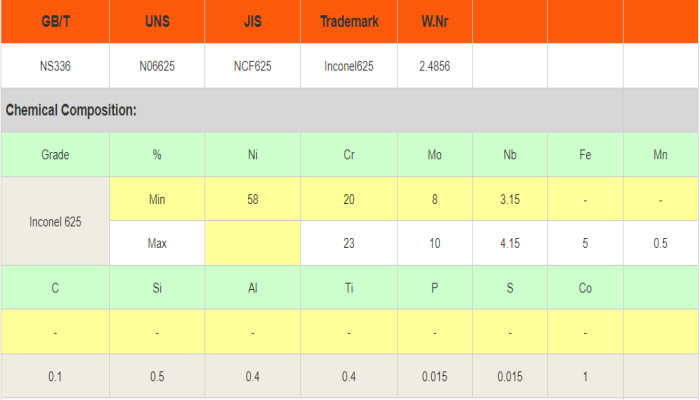

Inconel 625 is an austenitic nickel-chromium-molybdenum-niobium alloy. This material has very strong corrosion resistance and durability. It is widely used in gas turbine accessories and can still maintain a good condition under high temperature and high pressure conditions. This material is widely used in aerospace, energy industry, etc. For example, in gas turbine accessories, which our company is best at, it is often used in turbine blade materials because of its good performance.

1. Our manufacturing capabilities:

- Material preparation: According to customer needs, we selected ionconel625 after screening, and we conducted a comprehensive chemical composition analysis and mechanical property test on the materials we obtained to ensure the reliability of our material quality.

- Precision casting: Vacuum induction melting (VIM) plus electroslag remelting (ESR) or vacuum arc remelting (VAR) process is used to remove other impurities in the material and improve the accuracy of the material. Subsequently, directional solidification technology or single crystal growth method is used for precision casting to obtain a uniform and defect-free microstructure. This process can effectively avoid the common problems of shrinkage holes and bubbles in conventional casting processes, thereby greatly improving the quality of the finished product.

- CNC machining: Use multi-axis linkage high-precision CNC machine tools to perform complex geometric cutting. By programming the equipment, high-precision dimensional control and high surface finish can be achieved. In addition, CNC machining can also meet different design requirements, and can flexibly respond to the personalized use needs of different customers, providing unique products for each customized customer.

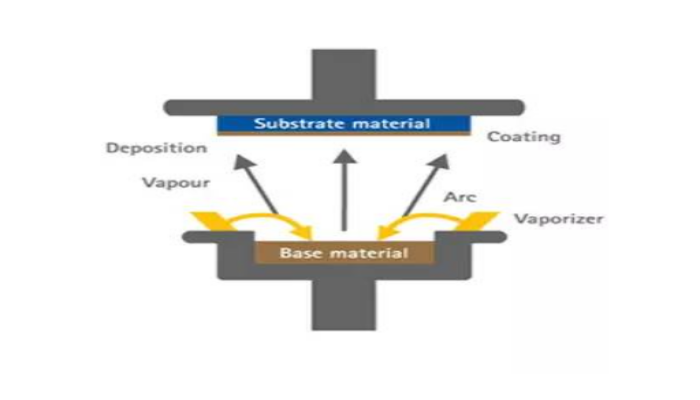

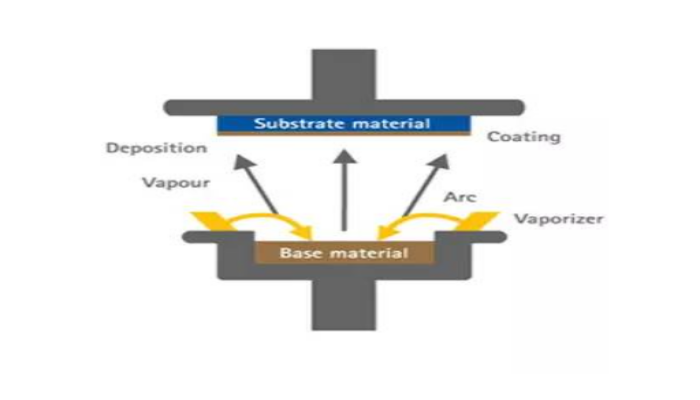

- Laser drilling and surface treatment: For turbine blades that require special cooling channels or other fine features, we use laser drilling technology to perform precise drilling. At the same time, in order to further improve the wear resistance and oxidation resistance of the product, we also use coating technologies such as physical vapor deposition (PVD) and chemical vapor deposition (CVD) to treat the surface.

2. Advanced testing methods

- Mechanical property testing: Strictly perform tensile tests, impact toughness determination and other projects in accordance with international standards to verify that the physical indicators of the material meet the requirements.

- Non-destructive testing: After production, we generally conduct ultrasonic and X-ray testing to check the internal and external organizational structures and comprehensively check whether there are defects.

- Three-dimensional scanning measurement: Use a three-dimensional scanner to perform a comprehensive scan, build a model, and compare the drawings provided by the customer to model and write a program.

3. Customized solutions

We are a company that integrates customization and reverse R&D. We value every customer and know that each customer has different usage requirements and usage scenarios. Therefore, from the initial communication, our technical team and sales team will work closely with customers to confirm their ideas. Whether it is for a specific usage scenario or to optimize product performance based on the original product, we will find the unique points of concern for each customer in the communication with customers, and are committed to creating better quality turbine blades for customers.

Conclusion

With years of accumulated experience and technical strength, we have successfully provided high-quality Inconel 625 turbine blade solutions to many well-known enterprises at home and abroad. In the future, we will continue to increase investment in research and development, explore more innovative applications, and help customers meet the changing technological challenges. If you are looking for a reliable partner to advance turbine technology together, do not hesitate to contact us!

Thank you for your interest in our company! As a professional gas turbine parts manufacturing company, we will continue to be committed to technological innovation and service improvement, to provide more high-quality solutions for customers around the world.If you have any questions, suggestions or cooperation intentions, we are more than happy to help you. Please contact us in the following ways:

- WhatsAPP:+86 135 4409 5201

- E-mail:peter@turbineblade.net