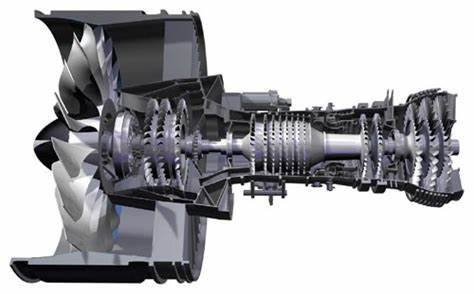

Guide vanes, those often overlooked yet vital components within gas turbines, play a crucial role in directing and controlling the flow of scorching hot, high-pressure gases, ensuring optimal efficiency, performance, and longevity for these powerhouses. They are the unseen architects of energy transformation, orchestrating the intricate dance of heat and pressure to produce usable power. At BLAZE, we specialize in crafting high-performance guide vanes from Inconel X-750, a superalloy renowned for its exceptional strength, heat resistance, and fatigue resistance. Beyond manufacturing, we offer expert reverse engineering capabilities, allowing us to reproduce and optimize even the most intricate guide vane designs, no matter the challenge. We are more than just manufacturers; we are problem solvers, committed to providing our clients with the most advanced and reliable guide vane solutions.

Inconel X-750: A Superalloy Tailored for Demanding Environments

Inconel X-750, a nickel-chromium-based superalloy, is a testament to the advancements in materials science, engineered to withstand the most demanding conditions. It is not merely a material; it is a testament to the relentless pursuit of innovation in the face of extreme environments. Its exceptional properties make it the ideal choice for guide vanes operating within the unforgiving environments of gas turbines, offering unparalleled performance and longevity:

- Exceptional Strength and Durability: Inconel X-750 boasts remarkable strength and durability, even at extreme temperatures, allowing it to withstand the immense forces generated within gas turbines. This exceptional strength ensures that the guide vanes can handle the high-pressure gas flow without bending, buckling, or failing, ensuring their continued performance and longevity.

- Exceptional Heat Resistance: Inconel X-750 exhibits exceptional thermal stability, maintaining its strength and integrity even at extreme temperatures exceeding 1000°C. This remarkable resistance to high temperatures is crucial for guide vanes, ensuring their reliable performance in the fiery heart of gas turbines. It allows them to withstand the intense heat generated during combustion without compromising their structural integrity, ensuring continued operational efficiency and minimizing downtime.

- Exceptional Fatigue Resistance: Inconel X-750 exhibits outstanding resistance to fatigue, a phenomenon where materials weaken and fracture under repeated stress cycles. This resistance is crucial in gas turbines, where the guide vanes experience constant stress from the high-pressure, high-temperature gas flow. By resisting fatigue, Inconel X-750 ensures the guide vanes maintain their structural integrity and function over extended periods, minimizing downtime and maintenance costs.

Reverse Engineering: Unveiling the Secrets of Design

We understand that not every guide vane is readily available, and that’s where our expert reverse engineering capabilities come into play. We go beyond traditional manufacturing, offering bespoke solutions to meet unique client needs, ensuring that no matter the challenge, we have a solution. This process involves:

- Detailed Analysis: Utilizing advanced 3D scanning and metrology techniques, we create precise digital models of existing guide vanes, capturing every intricate detail. This meticulous process allows us to recreate the exact geometry and dimensions of the original guide vane, ensuring that the new design replicates the performance of the original. This process provides us with a comprehensive understanding of the guide vane’s design, allowing us to identify key features and optimize its performance.

- Design Optimization: Our experienced engineers leverage these models to analyze the existing design, identifying areas for improvement and opportunities to optimize performance, efficiency, and durability. This approach allows us to refine existing designs or even create entirely new, bespoke solutions that are tailored to specific needs and operating conditions. We can leverage our knowledge to improve the flow dynamics of the guide vane, enhance its resistance to wear and tear, or even increase its overall efficiency.

- Precision Manufacturing: Utilizing state-of-the-art CNC machining, we ensure the precise fabrication of guide vanes with exceptional dimensional accuracy and surface finish, meeting the highest standards of quality and performance. This advanced manufacturing process guarantees that the finished product adheres to the stringent specifications required for optimal performance in gas turbines. We take meticulous care in every step of the manufacturing process, ensuring that the guide vanes we produce meet the highest standards of quality and precision.

Partner with BLAZE for Unmatched Guide Vane Excellence

At BLAZE, we combine the exceptional properties of Inconel X-750 with our expert reverse engineering capabilities, ensuring that our guide vanes meet the highest standards of performance, reliability, and longevity. We are your trusted partner for high-performance guide vane solutions, committed to delivering exceptional products and services. We believe that every client deserves a solution tailored to their unique needs and challenges. Contact us today to discuss your guide vane requirements and discover how we can help you achieve peak performance for your gas turbine operations.

[Contact information: Email, Phone, Website]

Let us help you power your operations with superior guide vane solutions!

For inquiries and collaborations, please reach out to us at:

[Peter@turbineblade.net]

[13544095201]

[https://turbineblade.net]

We look forward to partnering with you to ensure optimal performance for your gas turbine operations!