Inconel is a high-performance nickel-based alloy. It has excellent high-temperature strength, oxidation resistance and corrosion resistance.

Inconel is often used to manufacture turbine-related parts, such as turbine blades, turbine disks, etc. It can maintain good mechanical properties and stability in high-temperature environments and can withstand extreme temperature and pressure conditions. In aerospace, energy and other fields, Inconel is widely used due to its excellent performance, providing important guarantees for the reliable operation of related equipment.

High temperature resistance: Inconel alloy has excellent high temperature strength and oxidation resistance, and can maintain stable mechanical properties and structural integrity in extreme high temperature environments.

Corrosion resistance: This type of alloy has good resistance to oxidizing and reducing corrosive media, including high-temperature oxidation, sulfide corrosion, hydrogen corrosion, etc.

High strength: After solid solution strengthening and precipitation hardening treatment, Inconel alloy has significant mechanical strength and fatigue resistance, and is suitable for long-term high-stress working environments.

Good machinability: Despite its high strength and hardness, Inconel alloy still has good machinability and can be processed into complex parts through various processes such as forging, heat treatment, and machining.

Aerospace: Used in high-temperature components such as jet engines, turbine blades, combustion chambers, gas turbines, and rocket engines.

Chemical industry: suitable for corrosion-resistant equipment such as various chemical reactors, evaporators, furnace tubes, pipes and heat exchangers.

Energy sector: including nuclear energy, petrochemicals and power plants, used to manufacture nuclear reactor components, high-temperature boiler pipes and gas turbines.

Automotive industry: Used in high-performance engines, exhaust systems and turbochargers to improve high temperature and corrosion resistance.

Composition: Nickel (72%), Chromium (14-17%), Iron (6-10%)

Features: Excellent heat and oxidation resistance, widely used in corrosion-resistant parts in chemical equipment and nuclear reactors.

Composition: Nickel (58%), Chromium (20-23%), Iron (5%), Molybdenum (8-10%), Cast Copper (3.15-4.15%)

Features: Good corrosion resistance and high temperature strength, suitable for corrosion-resistant parts in seawater environment and nuclear industry.

Composition: Nickel (50-55%), Chromium (17-21%), Iron (18.5%), Titanium (2.8-3.3%), Aluminum (0.65-1.15%), Niobium (4.75-5.5%)

Features: High strength, fatigue resistance and corrosion resistance, commonly used in high temperature parts in aerospace and petrochemical fields.

Composition: Nickel (70.0%), Chromium (14-17%), Iron (5-9%), Titanium (2.25-2.75%), Aluminum (0.4-1.0%), Niobium (0.7-1.2%)

Features: Good high temperature resistance and oxidation resistance, suitable for high temperature parts of aircraft engines and gas turbines.

Composition:Nickel (Ni): 30-35%,Chromium (Cr): 19-23%,Iron (Fe): 39.5% Remainder,Aluminum (Al): 0.15-0.6%,Titanium (Ti): 0.15-0.6%

Features:

High strength and oxidation resistance, suitable for use in high temperature environments above 600°C.

Mainly used in petrochemical industry, heat treatment equipment, nuclear industry, etc.

Composition:Nickel (Ni): Balance (~75%),Chromium (Cr): 12-14%,Molybdenum (Mo): 4-6%,

Aluminum (Al): 5.5-6.5%,Titanium (Ti): 0.5-1%,Cobalt (Co): 0.0-2%,Carbon (C): 0.08-0.20%

Vanadium (V): 0.0-1.0%,Silicon (Si): ≤0.5%,Manganese (Mn): ≤0.5%,Boron (B): 0.005-0.020%

,Zirconium (Zr): 0.05-0.15%

Features

High temperature strength: Inconel 713 can still maintain high strength at high temperatures, making it suitable for components working under extreme temperature conditions.

Oxidation and corrosion resistance: This alloy performs well in high temperature oxidation and corrosion environments, suitable for use in harsh environments such as gas turbines.

Creep resistance: Inconel 713 has excellent creep resistance and can remain stable under long-term high-temperature operation.

Composition: Nickel (Ni): Balance (~61%), Chromium (Cr): 15.7-16.3%, Cobalt (Co): 8-9%, Molybdenum (Mo): 1.5-2%, Tungsten (W): 2.4-2.8%, Aluminum (Al): 3.2-3.7%, Titanium (Ti): 3.2-3.7%, Niobium (Nb): 0.7-1.2%, Tantalum (Ta): 1.5-2.1%, Carbon (C): 0.11-0.17%, Zirconium (Zr): 0.03-0.08%, Boron (B): 0.005-0.020%

Features

High temperature strength: Inconel 738 has extremely high strength at high temperatures and is particularly suitable for use in environments above 1200°C.

Creep resistance: When used for a long time at high temperatures, Inconel 738 has excellent creep rupture resistance.

Corrosion resistance: Excellent resistance to high temperature oxidation and hot corrosion, especially in oxygen-rich environments.

Composition: Nickel (Ni): Balance (~60%), Chromium (Cr): 11.7-13.5%, Cobalt (Co): 9-10%, Molybdenum (Mo): 1.7-2.3%, Tungsten (W): 3.8-4.4%, Aluminum (Al): 3.4-4.2%, Titanium (Ti): 3.5-4.3%, Tantalum (Ta): 3.9-4.5%, Carbon (C): 0.10-0.16%, Zirconium (Zr): 0.03-0.10%, Boron (B): 0.015-0.030%

Features

High temperature oxidation resistance: Inconel 792 has excellent oxidation resistance and hot corrosion resistance at high temperatures.

Creep rupture resistance: Suitable for components that need to maintain strength and stability for a long time at high temperatures.

Suitable Coatings: Inconel 792 is suitable for the application of thermal barrier coatings to further enhance its performance at elevated temperatures.

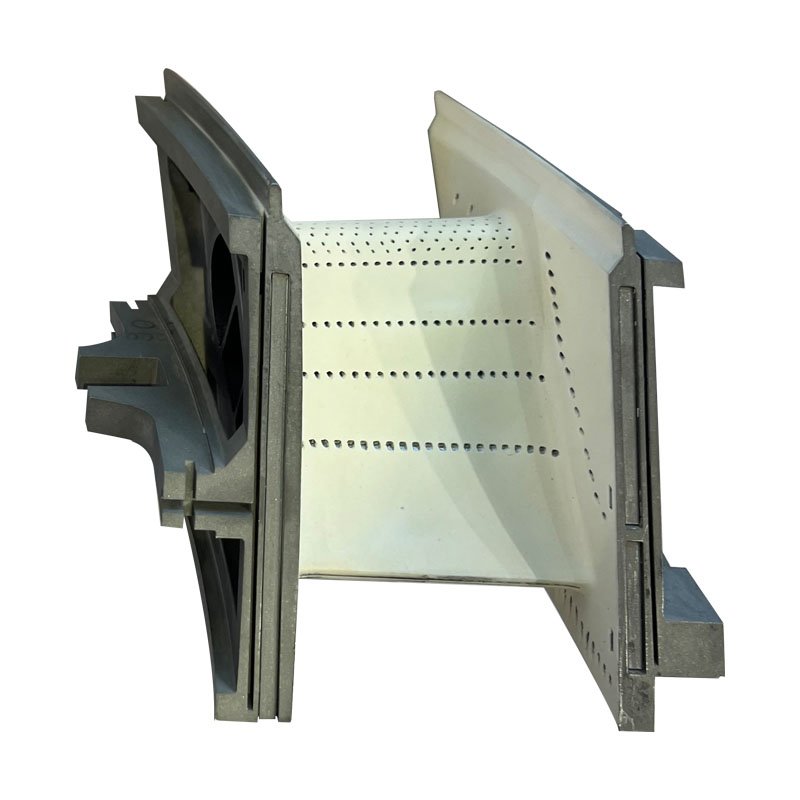

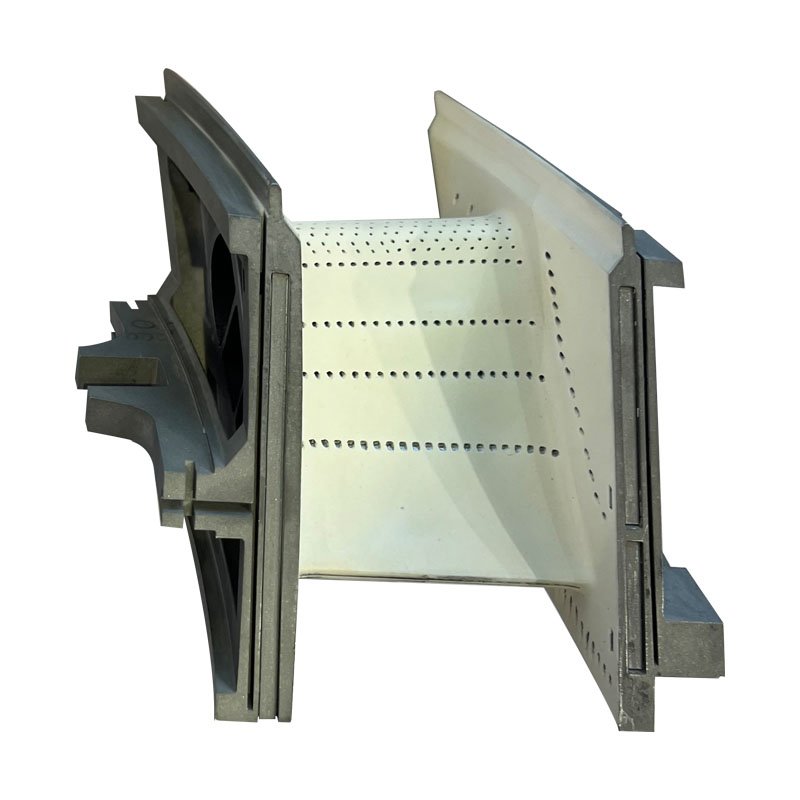

Turbine blades made of equiaxed casting are widely used in aircraft engines and gas turbines. These blades have good high temperature strength and corrosion resistance, and are suitable for high temperature and high pressure parts of turbines.

Turbine disks are important components that support turbine blades and transmit power. The equiaxed casting process can produce turbine disks with good mechanical properties and durability, which are suitable for various turbine equipment.

Combustion chamber liners need to work in high temperature and high pressure environments. The equiaxed casting process can produce liners with high temperature oxidation resistance and corrosion resistance.

Widely used in aircraft engines and gas turbines. This design helps to improve the manufacturing accuracy of blades, reduce stress concentration, and facilitate replacement and maintenance.

Guide vanes are used to adjust the airflow direction and improve the working efficiency of turbines. Equiaxed casting can ensure that these blades have uniform grain structure and good mechanical properties.

Engine turbine accessories also include several key components, each of which plays a vital role in the high temperature, high pressure and high speed environment of the engine.

Part numbers alone are not sufficient to ensure performance.

To guarantee precision and compatibility, please provide:

Drawings or used samples for reverse engineering.