The purpose of this paper is to discuss the application of Inconel 738 material in the manufacture of aero engine guide vane. Inconel 738 is a high performance nickel-based superalloy known for its excellent high temperature strength, corrosion resistance and good workability. Through a specific case study, we will deeply analyze the technical details of our company’s design and manufacturing process of Inconel 738 material guide vane and the performance advantages this material brings to our products.

1. Inconel 738 material characteristics

Inconel 738 is a nickel-based alloy designed for extreme environments and consists of nickel, chromium, cobalt, molybdenum and other elements. This alloy has the following outstanding characteristics:

- Weldability: Easy to weld, suitable for the manufacture of complex shaped parts.

- High temperature strength: high mechanical strength can be maintained even at temperatures above 650°C.

- Oxidation resistance: can effectively resist oxidation at high temperatures.

- Corrosion resistance: Good corrosion resistance to a variety of chemical media.

2. Guide vane design requirements

As one of the key components of aeroengine, the guide vane not only needs to withstand extremely high temperature, but also needs to have good aerodynamic performance and long life. Therefore, choosing the right material is crucial. The Inconel 738 is ideal for its unique performance.

3. Manufacturing process

3.1 Precision Casting

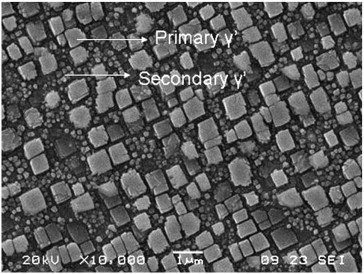

The Inconel 738 guide vane is usually manufactured using a precision casting process. The process can ensure high dimensional accuracy of the parts, good surface quality and dense internal organization. In addition, by controlling the cooling rate during solidification, it is possible to optimize the microstructure of the material and further improve its mechanical properties.

3.2 Heat Treatment

In order to achieve the best physical and mechanical properties, the Inconel 738 guide vane is subjected to a rigorous heat treatment process. This includes solution treatment, aging treatment and other steps to ensure that the material has a uniform microstructure and the required balance of hardness and toughness.

3.3 Surface Treatment

In order to enhance corrosion and wear resistance, the guide vane surface may also be subjected to special coating treatment or surface hardening treatment. These treatments help extend the service life of the guide vane and reduce maintenance costs.

4. Application Cases

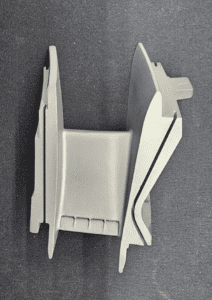

One of our customers is the power plant industry, for which our custom-made high pressure turbine forestage stator blades (i.e. guide blades) are made of inconel 737. Through the precise design and advanced manufacturing technology of our technical department, the guide vane not only meets the requirements of harsh operating conditions, but also enables lightweight applications, effectively improving the overall efficiency and reliability of the engine, and has been recognized by the customer.

5. Conclusion

With its excellent overall performance, the Inconel 738 shows great potential in the manufacture of high-temperature components such as aero-engine guide blades. In the future, with the continuous advancement of materials science and engineering technology, it is expected that Inconel 738 and similar materials will be more widely used in more fields.

Thank you for your interest in our company! As a professional gas turbine parts manufacturing company, we will continue to be committed to technological innovation and service improvement, to provide more high-quality solutions for customers around the world.If you have any questions, suggestions or cooperation intentions, we are more than happy to help you. Please contact us in the following ways:

- WhatsAPP:+86 135 4409 5201

- E-mail:peter@turbineblade.net