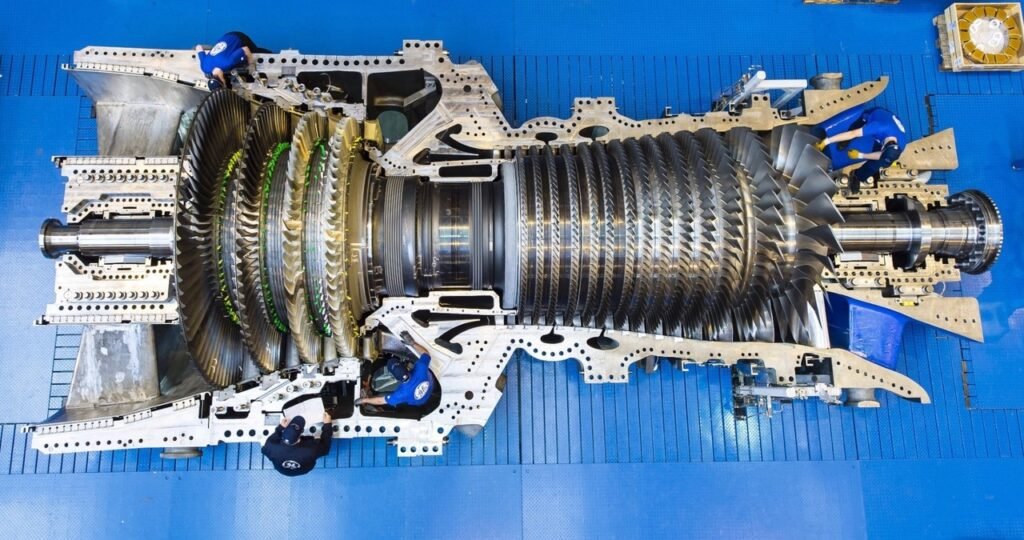

Turbine blades are at the heart of high-performance engines, where they must withstand extreme temperatures, pressures, and mechanical stresses. The choice of material is critical to ensure that these components can operate reliably under such harsh conditions. One of the most advanced materials used in modern turbine blade manufacturing is Inconel 939, a nickel-based superalloy known for its exceptional strength, corrosion resistance, and thermal stability.

The Advantages of Inconel 939 in Turbine Blades

Inconel 939 is specifically designed to meet the demanding requirements of aerospace and power generation applications. Here are some of the key advantages of using this material for turbine blades:

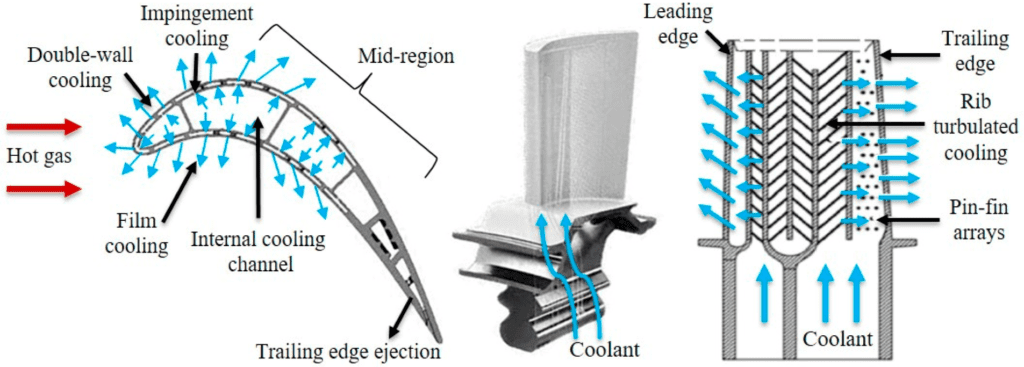

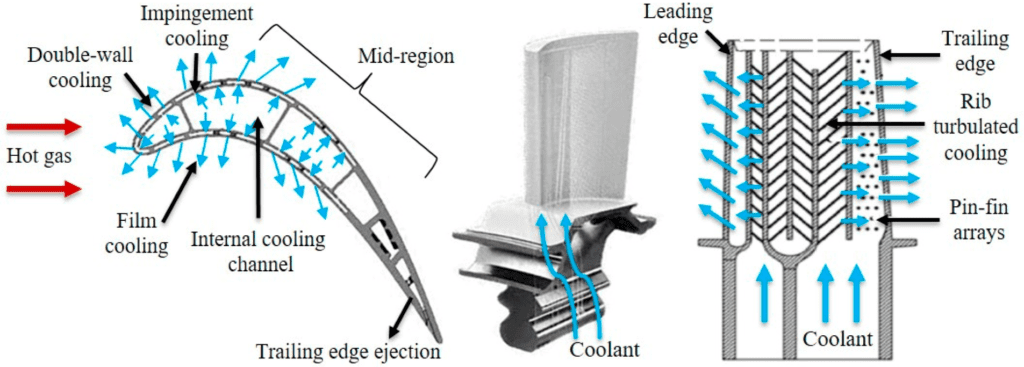

- High Temperature Strength: Inconel 939 retains its strength at elevated temperatures, making it ideal for use in gas turbine engines where operating temperatures can exceed 900°C (1652°F). This high-temperature strength ensures that the blades can maintain their structural integrity even under the most extreme conditions.

- Excellent Creep Resistance: The alloy’s microstructure provides superior resistance to creep, which is the tendency of a material to slowly deform under constant stress over time. This is crucial for ensuring long-term reliability and extending the service life of the turbine blades.

- Corrosion and Oxidation Resistance: Inconel 939 has excellent resistance to both oxidation and hot corrosion, which are common issues in high-temperature environments. This property helps to prevent degradation and prolong the lifespan of the blades.

- Fatigue Resistance: The material’s ability to resist fatigue, especially in cyclic loading conditions, ensures that the blades can endure the repeated stress cycles experienced during engine operation. This is particularly important in aerospace applications where the blades are subjected to frequent takeoffs and landings.

- Weldability and Machinability: Inconel 939 can be welded and machined, allowing for the creation of complex geometries and the repair of existing components. This flexibility in manufacturing processes makes it an ideal choice for both new designs and the refurbishment of existing parts.

The Role of Reverse Engineering in Turbine Blade Development

At BLAZE, we have extensive experience in reverse engineering, which allows us to replicate and improve upon existing designs. This capability is particularly valuable when working with Inconel 939, as it enables us to:

- Analyze and Optimize Existing Designs: By thoroughly examining and testing existing turbine blades, we can identify areas for improvement and enhance their performance. Our team uses advanced tools and techniques to conduct detailed analyses, including finite element analysis (FEA) and computational fluid dynamics (CFD), to simulate and optimize the design.

- Customize Solutions: Our expertise in reverse engineering allows us to tailor our solutions to specific customer needs, whether it’s for a new design or an upgrade to an existing component. We work closely with our clients to understand their requirements and deliver customized solutions that meet their exact specifications.

- Accelerate Development Cycles: By leveraging our knowledge and tools, we can significantly reduce the time and cost associated with developing new turbine blades, bringing products to market faster. Our streamlined processes and efficient project management ensure that we can deliver high-quality results within tight timelines.

Case Study: Enhancing Turbine Blade Performance

One of our recent projects involved the development of a new turbine blade for a commercial jet engine. The original blade, made from a different material, was experiencing premature wear and reduced efficiency. By reverse engineering the design and switching to Inconel 939, we were able to achieve significant improvements:

- Increased Service Life: The new blade showed a 30% increase in service life, reducing maintenance costs and downtime. This extended service life is a direct result of the superior properties of Inconel 939, which can better withstand the harsh operating conditions.

- Enhanced Efficiency: The improved material properties and optimized design resulted in a 10% increase in overall engine efficiency. This not only improves the performance of the engine but also contributes to fuel savings and reduced emissions.

- Reduced Weight: By fine-tuning the geometry and utilizing the superior strength-to-weight ratio of Inconel 939, we achieved a 15% reduction in blade weight. This weight reduction is critical in aerospace applications, as it directly impacts the overall weight of the aircraft and its fuel consumption.

Advanced Manufacturing Techniques

To ensure the highest quality and precision in our turbine blade manufacturing, we employ a range of advanced manufacturing techniques, including:

- Precision Casting: We use investment casting to create highly detailed and accurate turbine blades. This process involves creating a wax pattern, coating it with ceramic, and then melting out the wax to form a mold. The Inconel 939 is then poured into the mold, resulting in a precise and high-strength component.

- Heat Treatment: After casting, the blades undergo a carefully controlled heat treatment process to enhance their mechanical properties. This includes solution annealing, aging, and stress relieving, which help to optimize the material’s microstructure and improve its performance.

- Advanced Machining: Our state-of-the-art machining capabilities allow us to achieve the required tolerances and surface finishes. We use CNC machines and other precision tools to ensure that each blade meets the exact specifications.

- Non-Destructive Testing (NDT): To ensure the integrity of the final product, we perform various NDT methods, such as X-ray inspection, ultrasonic testing, and dye penetrant inspection. These tests help to detect any internal or surface defects and ensure that the blades are free from flaws.

Industry-Specific Applications

- Aerospace: In the aerospace industry, turbine blades made from Inconel 939 are essential for jet engines, where they must withstand the extreme conditions of flight. The material’s high-temperature strength and fatigue resistance make it an ideal choice for these applications.

- Power Generation: For power plants, whether they use gas turbines or steam turbines, the reliability of the turbine blades is critical for continuous and efficient power generation. Inconel 939 provides the necessary durability to ensure long-term performance and minimize maintenance.

- Industrial Machinery: In industries such as oil and gas, chemical processing, and heavy manufacturing, turbine blades are used in various types of equipment. The robustness and consistency provided by Inconel 939 make these components well-suited for these demanding environments.

Our Commitment to Excellence

At BLAZE, we are committed to delivering the highest quality turbine blades using the latest materials and technologies. Our team of experts combines deep industry knowledge with cutting-edge manufacturing techniques to provide solutions that meet and exceed our customers’ expectations. Whether you need custom-designed blades, reverse engineering services, or support for an ongoing project, we have the experience and capabilities to help you succeed.

Contact Us

To learn more about how BLAZE can support your turbine blade manufacturing needs, please contact us today. Our dedicated team is ready to discuss your specific requirements and offer tailored solutions to help you achieve your goals. Connect with us to discover how our expertise in Inconel 939 and reverse engineering can benefit your next project.