As a foreign trade company focusing on gas turbine parts manufacturing, we are always committed to providing customers with high performance and high reliability products through advanced materials and process technology. Equiaxed crystal casting technology shows significant advantages in turbine blade manufacturing because of its unique material characteristics and precision manufacturing process. This article will describe in detail our application of equiaxed crystal casting technology and its excellent results through a successful case.

1. Case background

Customer background: The Russian customer asked our company to produce a superalloy blade with excellent mechanical properties and longer service life at high temperatures, while reducing maintenance costs and downtime. After communication and discussion of the drawings, we decided with the customer the product direction of forging turbine blades with equiaxial crystals. Because their use scenarios face the challenge of improving the thermal efficiency of the engine and extending the service life, a new type of high-pressure turbine blade is needed, so the requirements for turbine blades are higher.

2. Material selection and process flow

In order to meet the strict requirements of customers, after communicating with customers, we chose high-quality nickel-based alloy as the main material and developed a strict production process.

(1)This alloy has the following characteristics:

- Excellent high temperature strength: can maintain high strength at extreme temperatures to ensure stable operation of the blade in high temperature environment.

- Good oxidation resistance: can resist oxidation corrosion at high temperature, extend the service life of the blade.

- Excellent fatigue resistance: exhibits excellent fatigue resistance under cyclic loads, reducing the risk of failure due to fatigue.

(2)Process flow:

- Material preparation: Select high quality nickel-based alloy raw materials, and carry out strict chemical composition analysis and mechanical properties test to ensure that the material meets the design requirements.

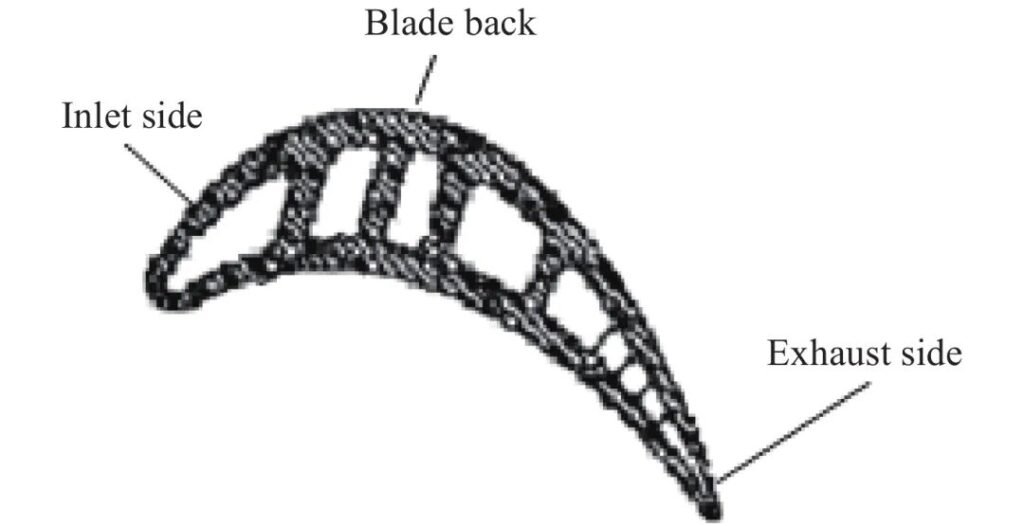

- Casting mold design: According to the detailed design drawings provided by customers, the casting mold is precisely designed by computer aided design (CAD) software. The design of the mold fully considers the cooling rate and temperature gradient to achieve a uniform equiaxed crystal structure.

- Melting and pouring: The alloy is melted in a vacuum induction melting furnace (VIM) to remove impurities and ensure the purity of the material. Then, the directional solidification technology is used to cast, and the cooling rate and temperature gradient are controlled to form a fine and evenly distributed equiaxed grain structure.

- Heat treatment: Through precisely controlled heat treatment process, further optimize the microstructure of the material, improve its mechanical properties and thermal stability.

- Machining and surface treatment: The castings are finished using high precision numerical control machine tools (CNC) to ensure dimensional accuracy and surface finish. Finally, the necessary surface treatment, such as coating or polishing, is carried out to enhance corrosion resistance and aesthetics.

- Quality inspection: Each blade is subjected to rigorous non-destructive testing (NDT), including X-ray inspection, ultrasonic inspection and magnetic particle inspection to ensure that there are no internal defects. In addition, mechanical properties testing and metallographic analysis are performed to verify the properties of the material.

3.Project implementation and customer feedback

- Project implementation: After a series of detailed preparatory work, we started mass production of the new high-pressure turbine blades. The entire production process is carried out in strict accordance with the ISO 9001 quality management system to ensure the quality consistency of each blade.

- Testing and verification: The production blades undergo rigorous bench testing and actual operation verification. The results show that the blades exhibit excellent mechanical properties at high temperatures, with a 30% increase in fatigue life and a 20% increase in thermal stability. In addition, customers’ overall operating costs are significantly reduced due to reduced maintenance frequency and downtime.

- Customer feedback: Customers speak highly of our product quality and technical support. The successful application of the new blade not only improves the thermal efficiency of the engine, but also prolongs the overhaul interval time, bringing significant economic benefits to the customer. Customers say their engines have reached new heights in terms of performance and reliability by adopting our equiaxed crystal casting technology.

conclusion

Through this real case of our customer, we have demonstrated the unique advantages of equiaxed crystal casting technology in turbine blade manufacturing. The combination of high-quality material selection and precision manufacturing processes enables us to provide our customers with high-performance, highly reliable turbine blades.

Thank you for your interest in our company! As a professional gas turbine parts manufacturing company, we will continue to be committed to technological innovation and service improvement, to provide more high-quality solutions for customers around the world.If you have any questions, suggestions or cooperation intentions, we are more than happy to help you. Please contact us in the following ways:

- WhatsAPP:+86 135 4409 5201

- E-mail:peter@turbineblade.net