In the high performance gas turbine industry, the turbine section is one of the key components, and its performance directly affects the efficiency and reliability of the entire system. Recently, our company received a new project recommended by an existing customer to customize a batch of Rough Forging turbine segments for a high-performance gas turbine. This project not only demonstrates our expertise in the industry, but also further strengthens our market position.

1. Customer demand

- Material requirements: Inconel 718 nickel-based superalloy is used to ensure excellent performance at high temperatures and pressures.

- Geometric accuracy: Strict control of dimensional tolerances ensures seamless integration with existing systems.

- Surface quality: Achieves a high standard of surface finish and reduces friction and wear.

Heat resistance and oxidation resistance: Advanced thermal barrier coatings are applied to improve the heat resistance and oxidation resistance of components.

2. Material selection and process flow

Material selection:

Inconel 718 was selected as the main material for its excellent high temperature strength, creep resistance and good weldability. This material can withstand temperatures up to 650°C and above, making it ideal for use in high-temperature components of gas turbines.

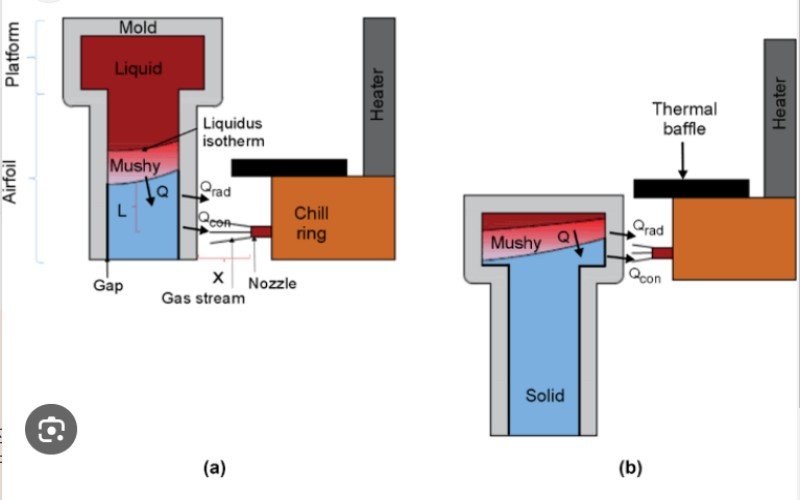

(1) Smelting and casting

Directional solidification (DS): Through directional solidification technology to control the direction of crystal growth, eliminate grain boundaries, improve the high temperature performance of materials.

Vacuum induction melting (VIM): VIM technology is used to ensure that the material is pure and free of impurities.

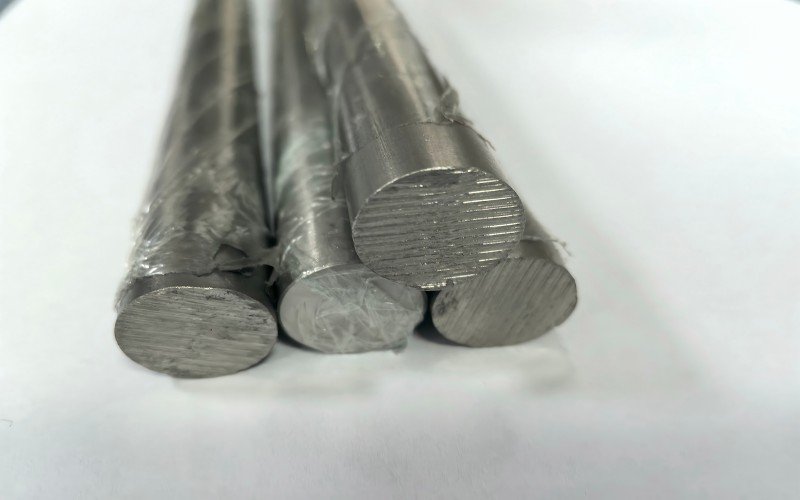

(2) Forging

Finish Forging: Refine the shape further through precision forging to achieve the required geometry and surface finish.

Rough Forging: Use large hydraulic forging equipment for preliminary forging to ensure uniform internal structure of the material and remove internal defects.

(3) Heat treatment

aging treatment: hold heat for a long time at a lower temperature to improve the hardness and strength of the material.

Solution treatment: The forging is heated to a specific temperature and quickly cooled to obtain a uniform microstructure.

(4) Mechanical processing

Grinding: grinding key parts to improve surface quality and dimensional accuracy.

CNC Machining: Precision machining with high-precision CNC machines ensures that each part meets strict dimensional tolerances.

(5) Surface treatment

- Shot Blasting: removes surface oxide and burrs to improve surface roughness.

- Coating: Ceramic thermal barrier coating (TBC) such as yttrium stabilized zirconia (YSZ) is applied to enhance the heat resistance and oxidation resistance of parts.

(6) Quality testing

- Non-destructive testing (NDT): including X-ray inspection, ultrasonic inspection, etc., to ensure that there are no internal defects.

- Dimensional Inspection: Accurate dimensional inspection is carried out using a coordinate measuring machine (CMM) to ensure that all components comply with the design

3. Project results

Through the above rigorous process process, we have successfully provided our customers with high quality Rough Forging turbine segments. These components not only fully met the customer’s technical specifications, but also demonstrated excellent performance in subsequent tests. Specific outcomes include:

- Geometric accuracy: All components meet or exceed customer specified dimensional tolerances.

- Surface quality: Extremely high surface finish is achieved through precision grinding and sandblasting.

- Heat resistance and oxidation resistance: The application of thermal barrier coatings significantly increases the service life of components at high temperatures.

- Overall performance: These turbine segments have demonstrated excellent mechanical properties and reliability in real-world customer tests.

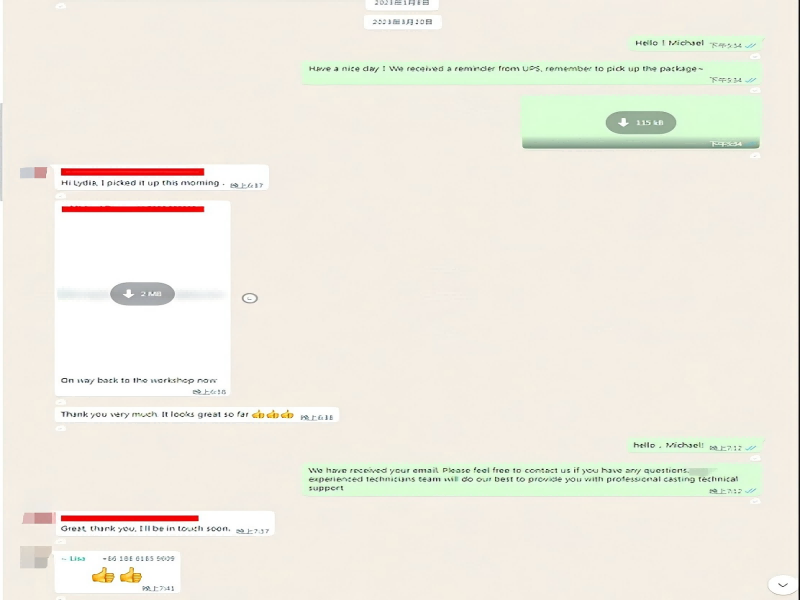

4. Customer feedback

The customer spoke highly of our expertise and the quality of our products and expressed their willingness to continue cooperation in the future. They particularly appreciate our rigorous approach to material selection, process control and quality inspection, as well as our ability to respond quickly and solve problems.

Thank you for your interest in our company! As a professional gas turbine parts manufacturing company, we will continue to be committed to technological innovation and service improvement, to provide more high-quality solutions for customers around the world.If you have any questions, suggestions or cooperation intentions, we are more than happy to help you. Please contact us in the following ways:

- WhatsAPP:+86 135 4409 5201

- E-mail:peter@turbineblade.net