As a company specializing in the foreign trade of gas turbine parts, we recently received a customized request from a power plant in Turkey to produce a batch of rough forged short turbine blades for their new gas turbine. These blades need to have extremely high heat resistance, strength and precision, and the customer has clear requirements for delivery times. Through the careful selection of materials, the use of advanced forging and machining technology, and the strict quality inspection process, we successfully delivered high-quality products on time and won high recognition from our customers.

1.material selection and precision forging

Forging process: After ensuring that the material is evenly heated to the appropriate temperature, multi-pass die forging is performed using a high-precision press. Throughout the process, the operator adjusts temperature and pressure in strict accordance with preset parameters to reduce internal defects and ensure blade consistency.

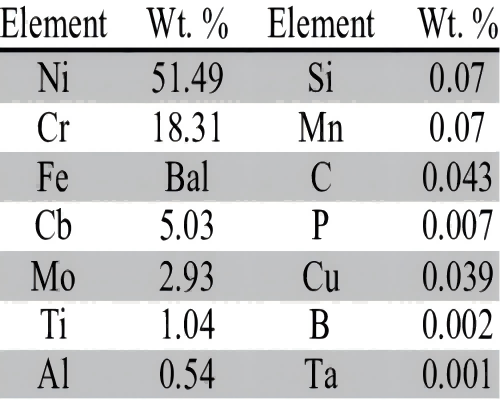

Material selection: After many communications with the customer and technical evaluation, Inconel 718 is finally selected as the main material of the blade. This nickel-based superalloy has good fatigue resistance and excellent mechanical strength.

2.efficient processing

Surface treatment: After the preliminary processing, the surface oxide layer is removed by sand blasting, and then finely polished to ensure the finished product has good appearance quality.

CNC programming optimization: The technical team uses advanced CAM software to develop an efficient machining path that not only increases efficiency but also reduces waste generation.

five axis machining: Using the latest five axis CNC machine tool for complex surface machining, to ensure that every detail is in accordance with the requirements of the design drawings.

3. strict quality control

Functional testing: Select samples and send them to the laboratory for a series of performance tests under simulated real working conditions, including but not limited to durability and vibration characteristics analysis.

Non-destructive testing: All semi-finished products are subject to X-ray inspection to confirm that there are no cracks or other defects before they go to the next process.

Dimensional verification: Complete measurement of key dimensions using a coordinate measuring instrument (CMM) to ensure that the margin of error is within permissible limits.

4. Deliver on time

- Logistics arrangements: Considering the uncertainties that international transport may face, a variety of alternatives are planned in advance to cope with unexpected situations.

- Packing protection: Each blade is carefully packed with shock-proof materials to prevent accidental damage during long-distance transportation.

- Customer acceptance: After the goods arrive in Turkey, local technicians carry out on-site unpacking inspection to confirm that the products are in good condition and then officially sign for receipt.

Customer feedback

The turbine blades were successfully installed in the generator set and put into operation, showing excellent stability and reliability. The customer spoke highly of this collaboration, believing that it not only improved the overall performance of the equipment, but also increased their confidence in future projects.

Thank you for your interest in our company! As a professional gas turbine parts manufacturing company, we will continue to be committed to technological innovation and service improvement, to provide more high-quality solutions for customers around the world.If you have any questions, suggestions or cooperation intentions, we are more than happy to help you. Please contact us in the following ways:

- WhatsAPP:+86 135 4409 5201

- E-mail:peter@turbineblade.net