Turbine blades are critical components in power generation, aviation, and other industries, demanding high performance and durability. Reverse engineering these complex components offers a powerful pathway to improve existing designs, develop new technologies, and enhance overall system efficiency.

Customers send samples for product data analysis

- The customer sends samples to confirm the material, grain and internal structure, which are equiaxial wafers

- Material analysis

- Coating analysis, issue surface coating analysis report and make coating plan

- Perform CMM scan to determine the basic size

- Conduct CT scan, material analysis and determination, accurate measurement of internal channel size and outline size, and internal track discussion with customers

- Establish the data model of the blade, and make 3D drawings and 2D drawings

Carry out mold making

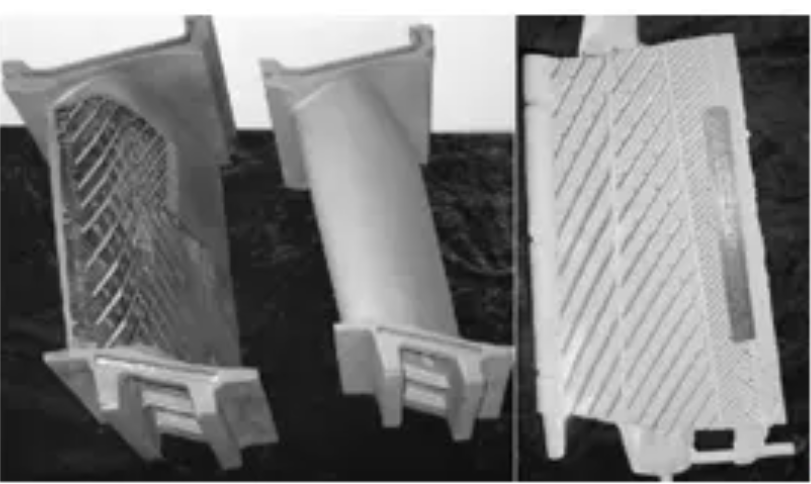

Ceramic core mold makin

- Hand molding: For simple shapes, cores can be manually formed using molds and pressing techniques.

- Investment casting: A wax pattern is created, coated with ceramic slurry, and then the wax is melted out, leaving a ceramic core.

- 3D Printing: Advanced techniques like 3D printing allow for intricate and complex core designs.

Metal mold making

- Hand molding: For simple shapes, cores can be manually formed using molds and pressing techniques.

- Investment casting: A wax pattern is created, coated with ceramic slurry, and then the wax is melted out, leaving a ceramic core.

- 3D Printing: Advanced techniques like 3D printing allow for intricate and complex core designs.

Wax molding

- Mold making: Molds are made according to wax mold design, usually using metal or resin materials. The precision and finish of the mold directly affect the quality of the wax mold.

- Wax injection: molten wax material is injected into the mold and cooled to form a wax mold. The wax injection process needs to control parameters such as temperature, pressure and speed to ensure the integrity and accuracy of the wax mold.

- Stripping: Remove the wax mold from the mold. Care should be taken to avoid damaging the wax mold during the release process.

Casting link

Sand shell mold: Sand shell mold, also known as sand mold, is one of the most commonly used mold types in the casting process. It uses mixed sand as a mold material and is made by modeling, core making, drying and other steps.

Vacuum casting

- High quality casting: Because the gas is removed, the casting surface is smooth, the internal structure is dense, and the dimensional accuracy is high.

- Good surface finish: The casting surface is smooth and does not require additional machining.

- Complex shapes: Vacuum casting can produce a variety of complex shapes, including thin-walled, slender and internal cavities.

- Improve metal utilization: vacuum casting can reduce the production of waste and improve metal utilization.

There are many methods of blank production, and the common ones are as follows:

- casting: Molten metal is poured into the mold, cooled and solidified to form the casting blank.

- forging: The use of mechanical pressure to shape metal materials to obtain forging blanks.

- stamping: The use of punching press to press sheet metal forming, stamping parts blank.

- extrusion: The use of mechanical pressure to extrude metal materials to form, to obtain extruded blank.

- cutting: The use of tools to cut metal materials, to obtain cutting parts blank.

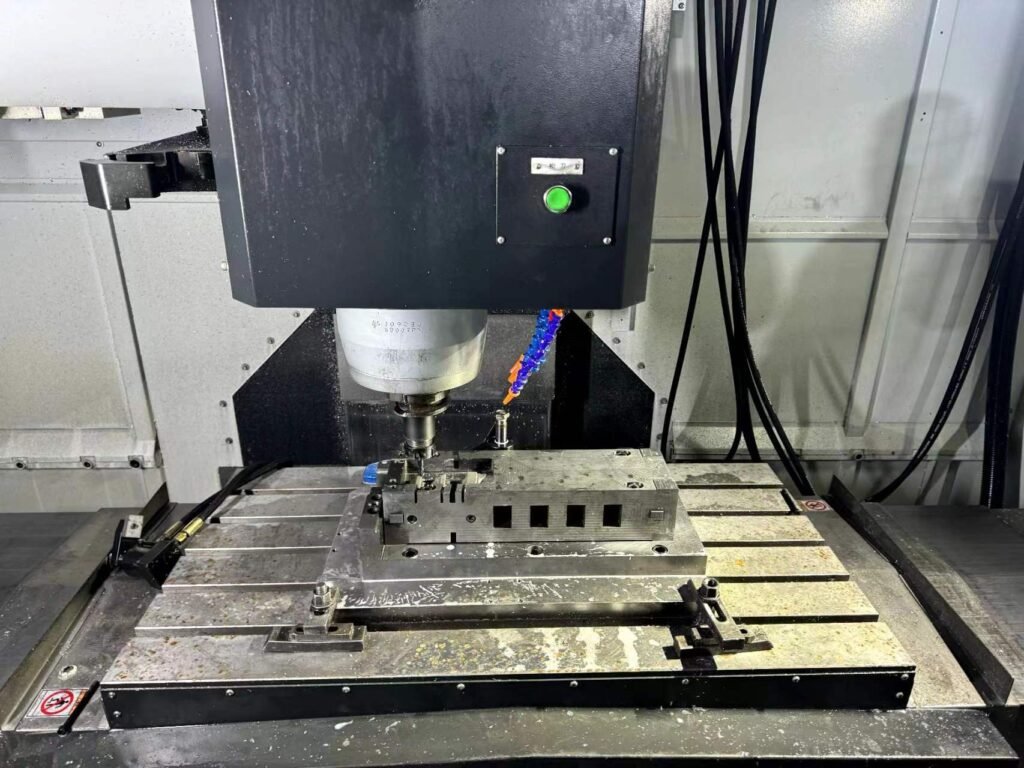

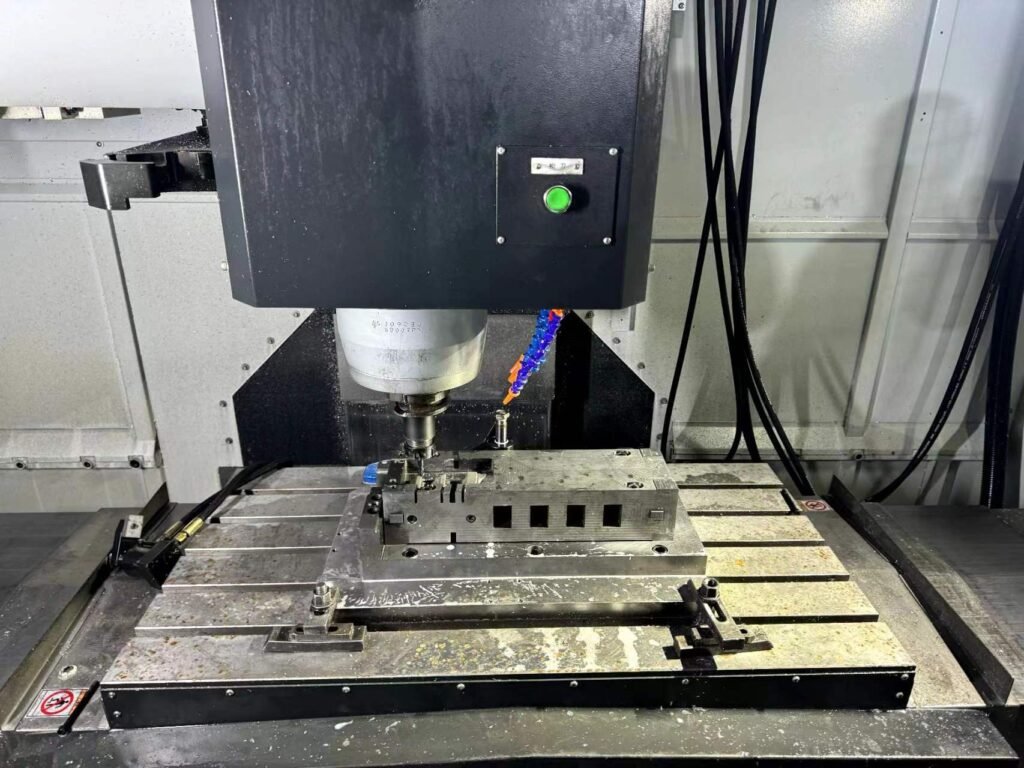

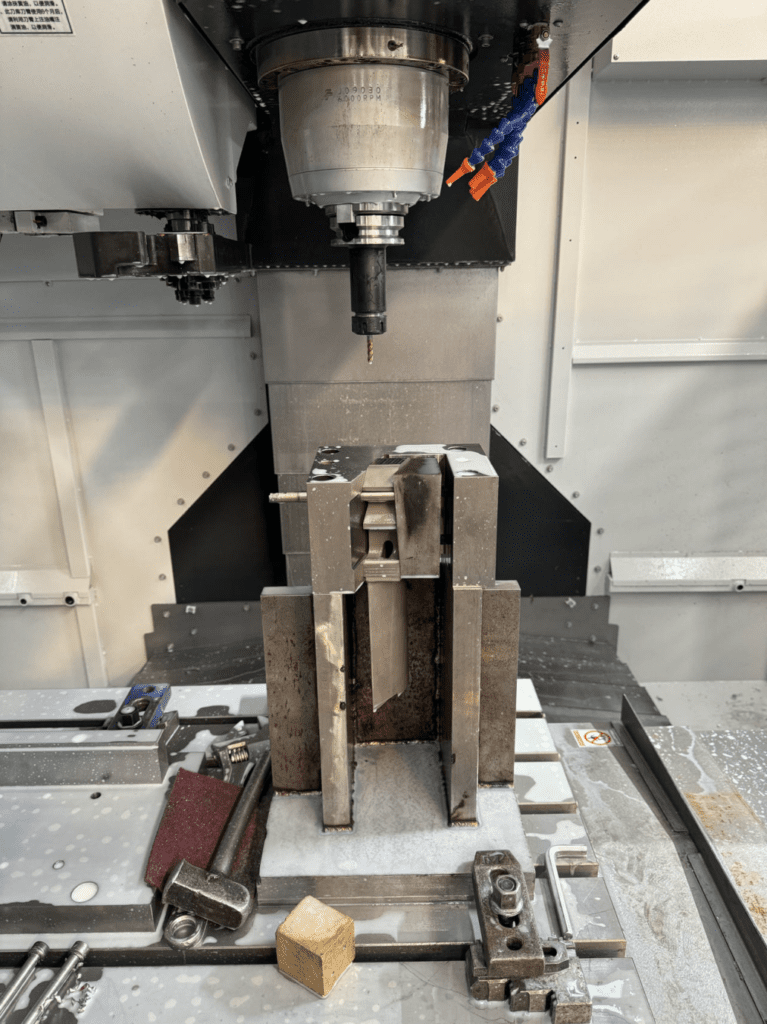

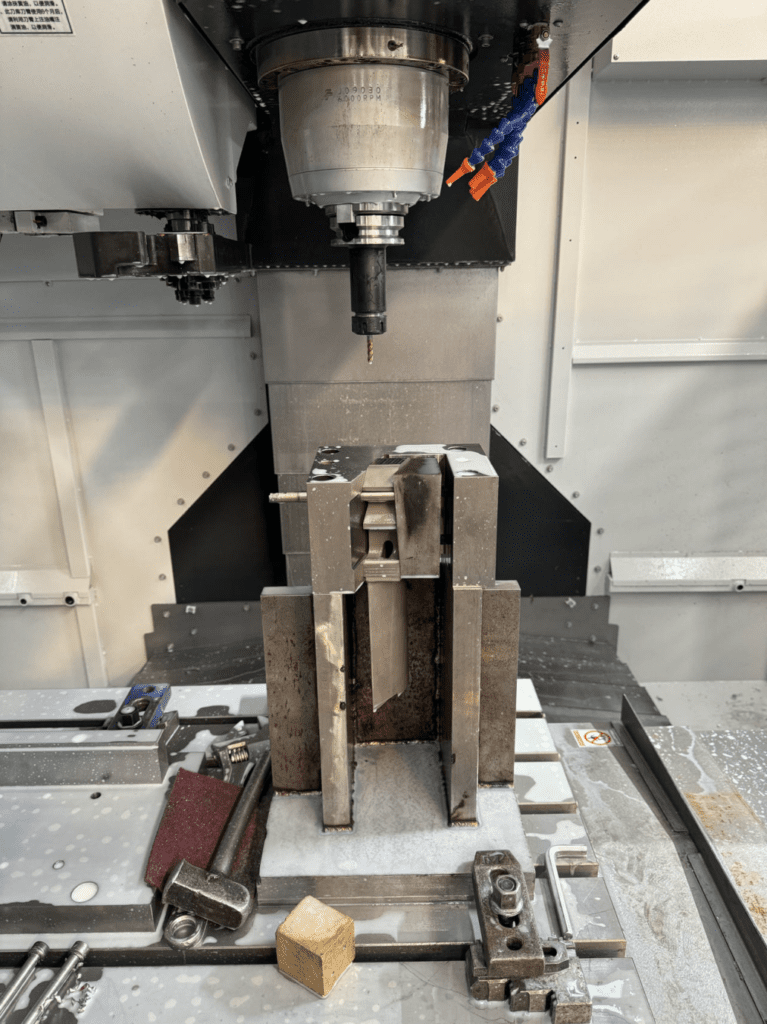

Machining the product

Machining the product means further processing of the blank to achieve the final design requirements and dimensional accuracy of the product

Machining steps:

- Choose the processing method: according to the material, shape, size and accuracy requirements of the product, choose the appropriate processing method.

- Select the processing equipment: according to the processing method, choose the appropriate processing equipment.

- Develop the processing technology: develop the specific processing flow, including the selection of tools, the setting of cutting parameters, the arrangement of the process, and so on.

- Processing: According to the processing technology, the processing equipment is used to process the blank.

- Inspection and adjustment: After the processing is completed, the product needs to be inspected to ensure that its size, shape and surface finish meet the design requirements. If there is a deviation, it needs to be adjusted

Finished product

The finished product is finished, which means that after a long process of design, research and development, production, inspection and other links, the final product has been published.

After the finished product is completed, the following steps are generally carried out:

- Packaging: In order to protect the product and facilitate transportation and storage, packaging is required. Packaging can be simple carton packaging, or it can be beautiful gift box packaging, depending on the type of product and market positioning.

- Transportation: After the product is packaged, it needs to be shipped to the customer. The mode of transportation can be road transportation, rail transportation, air transportation, water transportation, etc., depending on the volume, weight, destination and other factors of the product.

- After-sales service: After the product arrives at the hands of customers, we also need to provide corresponding after-sales service, such as warranty, repair, maintenance and so on. Good after-sales service can enhance customer satisfaction and enhance brand loyalty.

Issue product test report

The product testing report is a very important part of the product production process, which reflects the quality and reliability of the product.

Issue product test report

- Ensure product quality: the test report can prove whether the product meets the national standards, industry standards or internal standards of the enterprise, ensure the quality and reliability of the product, and avoid quality problems.

- Improve customer trust: test reports can provide customers with product quality assurance, enhance customers’ trust in products, and enhance brand image.

- Meet the regulatory requirements: some products require mandatory testing certification, such as food, drugs, medical devices, etc., the issuance of test reports is a necessary condition for product sales.

- Improve product competitiveness: the test report can be used as proof of product quality, improve the market competitiveness of products, and help enterprises win more customers and orders.

Contact Us

Don’t miss the opportunity to contact us for more information on turbine blade reverse development!