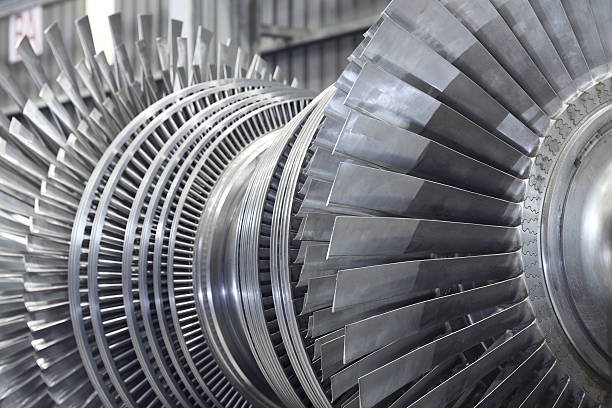

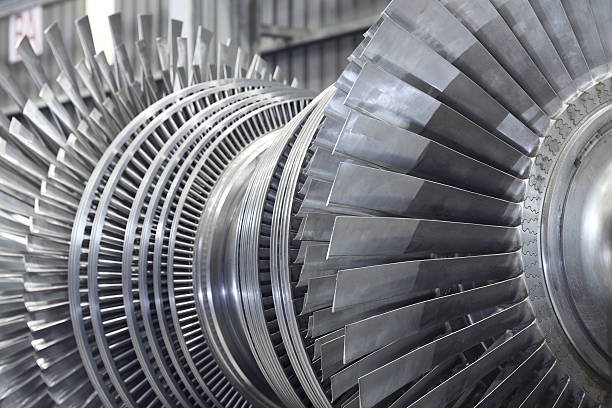

Abrasive sealing coatings play a vital role in controlling the clearance between the aircraft engine housing and the blade tip, enhancing air tightness and protecting the blade tip. This paper describes a key structure: multilayer porous structure, multilayer porous structure is widely used, by controlling porosity balance wear resistance structural strength, oxidation and corrosion resistance.

In order to reduce the fuel consumption and improve the working efficiency of aero engine, sealing is widely used in the combination of dynamic and static parts of engine for gas path sealing. There is a gap between the blade tip and the casing of an aeroengine, and too large a gap seriously affects the efficiency and energy consumption of the engine, reduces the endurance of the aircraft, and increases its operating cost. The influence of blade tip radial clearance on the work efficiency and fuel consumption of each component of aviation engine is shown in Figure 1. For example, if the ratio of blade tip clearance to blade length increases by 1%, the efficiency of turbine blade will decrease by about 1.5%, and the corresponding fuel consumption will increase by about 3%.

The structural characteristics of abrasive sealing coatings have an important effect on the performance and service life of coatings, but there is a lack of systematic introduction in this respect. The sealing coating is mainly used to control the clearance between the casing and the blade tip of the aircraft engine, improve the air tightness between the casing and the blade tip, and protect the blade tip as a sacrificial coating to prevent “hard” collision during the collision between the blade tip and the casing. Three kinds of sealing coatings with multi-layer porous structure, honeycomb-coating composite structure and nanostructure and their preparation techniques are reviewed. It is found that multi-layer porous structure is still the main application structure of sealing coating, and this structure can achieve the balance of wear property, structural strength, oxidation resistance and corrosion resistance of coating by regulating coating pores during spraying. Combining the advantages of honeycomb structure sealing and abrasive sealing coating, the honeycomb – coating composite structure sealing was designed and prepared, which can improve the structural strength and oxidation resistance of the sealing. With the development of nanotechnology, the nanostructured sealing coatings have been designed and prepared. Compared with the traditional abrasive sealing coatings, the nanostructured sealing coatings show better comprehensive properties. Finally, it is proposed that nano-structure and bionic structure may become the development trend of the future design of aircraft engine abrasion-sealing coating structure, and the maturity of 3D printing technology will be able to prepare more diversified coating structures. The research results are of reference significance for the structural design, preparation and practical application of the abrasible sealing coating.

In order to reduce the fuel consumption and improve the working efficiency of aero engine, sealing is widely used in the combination of dynamic and static parts of engine for gas path sealing. There is a gap between the blade tip and the casing of an aeroengine, and too large a gap seriously affects the efficiency and energy consumption of the engine, reduces the endurance of the aircraft, and increases its operating cost. The influence of blade tip radial clearance on the work efficiency and fuel consumption of each component of aviation engine is shown in Figure 1. For example, if the ratio of blade tip clearance to blade length increases by 1%, the efficiency of turbine blade will decrease by about 1.5%, and the corresponding fuel consumption will increase by about 3%.

At present, the wear sealing between the casing and blade tip is mainly divided into honeycomb structure and wear sealing coating. The honeycomb structure sealing is generally made of nickel-based material, which is welded on the inner wall of the casing by brazing process. As the wear side in the friction process, the abrasive seal needs to be re-prepared and repaired every certain time. The honeycomb structure seal has the disadvantages of complicated brazing process and inconvenient maintenance. The abrasive seal coating is used by more and more aero engines to seal between the blade tip and the casing due to its relatively simple preparation process and easy maintenance.

The sealing coating can be divided into low temperature sealing coating (below 400℃), medium temperature sealing coating (400 ~ 800℃) and high temperature sealing coating (above 800℃) according to the working temperature. At present, the medium and low temperature sealing coatings developed can meet the requirements of the corresponding engine working conditions. However, with the continuous increase of thrust-to-weight ratio of aero-engines, the turbine front temperature of aero-engines exceeds 1 800℃, and the working performance of the high-temperature sealing coating at high temperature has been challenged unprecedentically. Improving the working performance of the high-temperature sealing coating has become a research focus. Common high temperature sealing coatings can be divided into MCrAlY alloy based superalloy sealing coating and Y2O3 partially stabilized ZrO2 (YSZ) based ceramic sealing coating. At present, GE Company and Metco company as representatives, developed a variety of high-temperature alloy and high-temperature ceramic sealing coating, its research and development technology is in the forefront of the world. In recent years, Chinese researchers have also conducted a lot of research on the preparation technology of high-temperature sealing coating and how to improve its service performance, including coating material selection, process parameter optimization and structural design, and these studies have also achieved good results.

In the process of blade friction with abrasive sealing coating, the wear mechanism is complicated, including scraping, adhesive wear, high temperature oxidation and corrosion. In addition, the coating also has to withstand the erosion of high-speed air flow and foreign particles, which is easy to fall off. Therefore, the ideal abrasion sealing coating should have good comprehensive properties, taking into account the performance of abrasion, corrosion resistance, oxidation resistance, thermal shock resistance and so on. The high temperature performance of sealing coating can be improved through the design of coating material system, coating structure design and preparation process optimization. In the past few decades, researchers have mainly studied how to improve high temperature performance through the design of sealing coating material system; In recent years, the structural design of sealing coatings has attracted the attention of researchers, especially with the development of biomimetic materials, heterogeneous materials, composite materials, nanomaterials and other technologies, some sealing coatings with new structures have been designed and prepared.

In this paper, the common casing-tip abrasive sealing structures and their preparation methods for aero-engines are reviewed, and the influence of different structures on the microstructure, hardness, oxidation resistance, corrosion resistance and thermal shock resistance of coatings is reviewed. The future development direction of the design and preparation of casing-tip sealing structures is also proposed.

Multi-layer porous sealing coating structure

The common sealing structure is multi-layer and porous structure, and the coating mainly includes a bonding layer and a top abrasive layer. In addition, after the sealing coating works in a high temperature environment for a period of time, due to oxidation reaction with oxygen in the air, a Thermal growing oxidation layer (TGO) will be generated between the bonding layer and the top abrasive layer. The internal binding force of the multi-layer structure coating is not strong, and the coating is easy to fall off and wear under blade tip friction and high temperature and high pressure airflow erosion.

The pores of the coating are distributed throughout the coating to ensure that the coating has good abrasiveness. However, too many pores will weaken the binding force inside the coating, but also facilitate oxygen intrusion into the coating, indirectly promote the oxidation reaction, so that TGO rapid growth, resulting in premature coating spalling failure. It can be seen that the performance of the abrasive sealing coating is not only related to the layered structure, but also closely related to its porosity . In order to obtain abraded sealing coatings with excellent comprehensive properties, various materials and preparation processes were used to prepare sealing coatings with different porosity, and the effects of coating structure and porosity on coating properties were investigated.

The most common preparation technologies for traditional structural sealing coatings are Atmospheric plasma spraying (APS) and Flame spraying (FS). Using APS and FS technology, researchers have prepared a series of sealing coatings with different materials and adapted to different working conditions, some of which have been applied to aircraft engines.

IRISSOU et al. obtained sealing coatings with different microstructure and porosity by adjusting spraying process parameters, and found that reducing porosity can increase coating hardness and bonding strength, but too low porosity weakens the abratability of the coating, which may lead to leaf damage during the interaction with the blade. By changing the spraying distance and the acetylene flow rate, the coating microstructure can be changed, and the sealing coating with different porosity (30%-70%) can be obtained.

As shown in Figure 3, when the acetylene flow rate is 300 L/h, the spraying distance has a significant effect on the coating microstructure, and the porosity decreases with the increase of the spraying distance. When the spraying distance is 60 mm, the porosity decreases with the increase of acetylene flow rate. The reason is that when the spraying distance and acetylene flow rate increase, the melting degree of the spraying material will increase, and the deposited coating will be dense and the porosity will decrease, as shown in Figure 4. CHENG et al. [36] used APS and FS technologies to prepare a three-layer layer sealing coating of NiCrFeAlN-YSZ-NiCrAl on a titanium alloy (Ti2AlNb) matrix (as shown in Figure 5). NiCrFeAlBN is the top wear layer, YSZ is the middle transition layer, NiCrAl is the bonding layer. The whole coating is well combined, each layer has uniform microstructure, moderate hardness, and good thermal cycling performance, which can meet the working requirements of high-pressure compressor.

(Fig.4 Variation trend of porosity of coating)

Fig.3 Comparison of the microstructure of the coatings at three different spraying distances (acetylene flow rate: 300 L / h) and comparison of the microstructures of the coatings at three different acetylene flow rates (spraying distance: 60 mm)

Cheng Tao Tao et al. [In order to improve the mechanical properties of the layered structure coating and avoid premature peeling of the ceramic surface of the traditional sealing coating, a “brick-mud” layered structure with strong toughness was designed to mimic the shell structure, as shown in Figure 6. Yttrium aluminum garnet was used as the bonding phase and ceramic agglomeration particles were prepared by spray granulation method. Then, APS technology is used to prepare the “brick” layer coating, isopropyl alcohol and MK resin are stirred to make “mud”, and then sprayed on the surface of the sealing coating. In the thermal cycle test, the “mud” layer cracks preferentially, consumes most of the thermal stress, protects the “brick” layer structure, and improves the thermal cycle life of the coating.

Fig.5 Surface morphology of cross-section of three-layer layered structure sealing coating

prepare the nail-like structure on the surface of the traditional substrate, and then sprayed the sealing coating on the nail-like structure. This structure is conducive to coating deposition, and a locking structure is formed between the coating and the substrate, as shown in Figure 7, so as to increase the bonding strength of the coating and the substrate and improve the coating’s resistance to spalling.

The traditional multi-layer porous structure sealing coating is difficult to meet the three performance requirements of hardness, bond strength and abratability by adjusting the porosity, which is the contradiction that the existing structural coating is difficult to reconcile. To solve this problem, TONG et al. proposed a new type of spherical closed-cell structure, whose surface morphology is shown in Figure 8. Graphite, phenolic resin hollow microspheres (HMS) and epoxy resin colloids were mixed together and then sprayed on the substrate. The graphite particles were added to improve the self-lubrication of the coating and avoid excessive wear of the blade. HMS plays the role of pores and reduces the hardness of the coating. Compared with the traditional structural sealing coating, the new spherical closed-cell structure coating has good mechanical properties, taking into account the requirements of hardness and bonding strength, and the coating shows good wear ability.

This advanced coating consists of multiple porous layers, each designed for specific functions. It improves thermal insulation, reduces heat transfer, and accommodates thermal expansion, thereby minimizing thermal stresses. The porous layers also provide excellent sealing, preventing corrosion and wear from harmful gases and particles. This structure enhances the durability and efficiency of gas turbine components.

Thank you for your interest in our company! As a professional gas turbine parts manufacturing company, we will continue to be committed to technological innovation and service improvement, to provide more high-quality solutions for customers around the world.If you have any questions, suggestions or cooperation intentions, we are more than happy to help you. Please contact us in the following ways:

- WhatsAPP:+86 135 4409 5201

- E-mail:peter@turbineblade.net