As a foreign trade company specializing in gas turbine components, BLAZE Shenzhen has recently partnered with an electric energy company based in Iran. The company encountered a difficult problem when operating multiple natural gas power stations: Frequent cracks and wear on conventional turbine blades at high temperatures and pressures led to frequent downtime, increased maintenance costs, and affected the overall efficiency of the plant. To solve this problem, we recommended and implemented Directional Casting technology to our customers to produce new turbine blades.

1. Advanced directional solidification casting process Directional solidification casting is a highly accurate metal processing method that reduces the number of grain boundaries, especially those that are prone to defects, by controlling the direction of crystal growth during metal melt cooling. Our process includes the following key steps:

- Mold design and preparation: First of all, we make high-precision molds according to the needs communicated with us by customers and the design requirements of turbine blades.

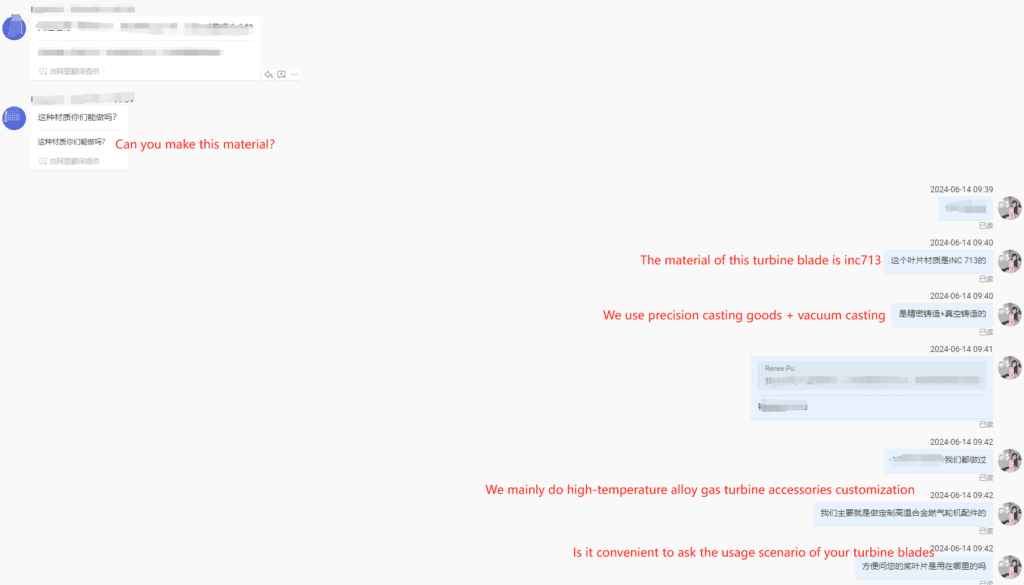

- Melting and pouring: After confirming the material and application with the customer, we decide on a high quality nickel-based superalloy material and melt the material under vacuum or inert gas protection, and then inject the molten metal into a mold preheated to the appropriate temperature.

- directional solidification: The bottom of the water-cooled copper mold is gradually moved upward to ensure that the liquid metal is gradually cooled and solidified from the bottom to form a columnar crystal structure arranged in the vertical direction. In this process, the cooling speed is strictly controlled to avoid the formation of unfavorable organizational patterns.

- Post-treatment: After the casting of the turbine blade, we need to carry out precision machining, surface treatment, etc., to ensure that its dimensional accuracy and surface quality meet the highest standards.

2.High Quality material selection In order to meet the performance requirements under extreme operating conditions, we choose nickel-based superalloys as raw materials. This alloy has excellent high temperature strength, good oxidation resistance and corrosion resistance. In addition, through the use of this Iranian customer, our technicians adjusted the alloy composition, adding the appropriate amount of cobalt, tungsten or molybdenum elements to further optimize the overall properties of the material, making it more suitable for long-term continuous operation applications.

3.A wide range of applications Our turbine blades produced by directional solidification casting technology are not only suitable for ground power station projects, but also have been successfully applied to civil helicopter engines, Marine propulsion systems and other fields. For this Iranian customer, the newly installed turbine blades significantly reduced failure rates, extended equipment life and reduced unnecessary downtime. This translates directly into higher power generation efficiency and lower operating costs, resulting in significant economic benefits for customers. At the same time, due to the reduction of the frequency of replacement, it also reduces the impact on the environment, reflecting the concept of sustainable development.

4. Summary of product advantages Through this successful cooperation case, our Shenzhen BLAZE company has proved its strength in technological innovation and service quality. Our directionally solidified turbine blades solve the practical problems of our customers with their unique production process, selected high-quality materials and wide application range. In the future, we will continue to focus on developing more efficient and durable products that continue to meet the needs of our customers worldwide and drive the entire industry forward.

If you are interested in our directional casting wheel blade technology, or want to learn more about how this advanced process can improve the performance and efficiency of your gas turbine, please feel free to contact us. We are committed to providing high quality gas turbine fitting solutions to our customers worldwide and have the experience and expertise to meet your specific needs.

- WhatsAPP:+86 135 4409 5201

- E-mail:peter@turbineblade.net