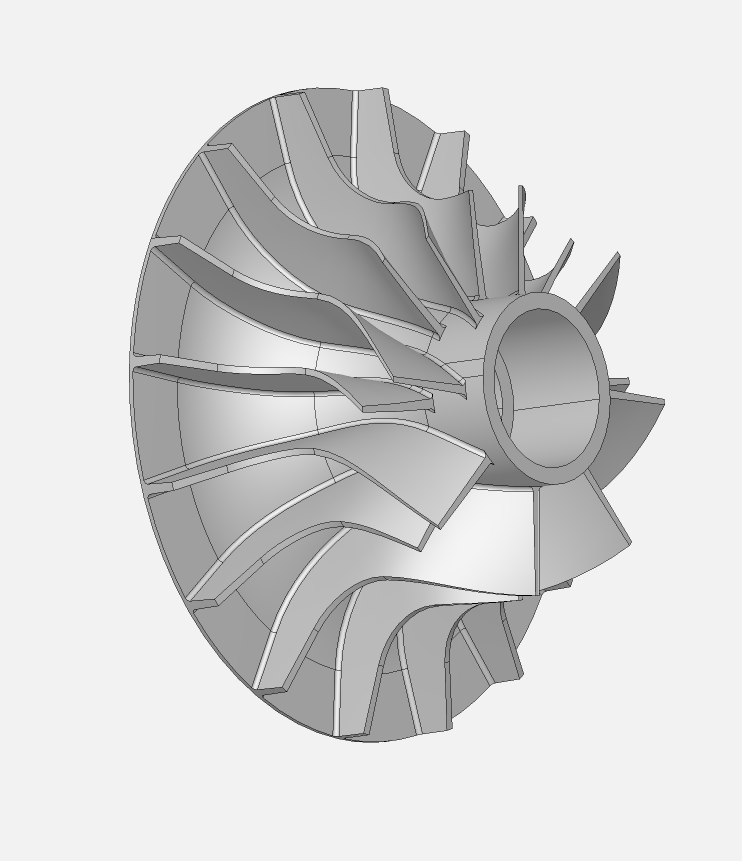

In recent years, turbine modification has become increasingly popular in China, among which high-performance turbines using forged CNC inlet blades are highly respected. These blades, typically made of high temperature alloy, are not only stronger, but can also be designed to be thinner and longer, resulting in greater air flow at the same speed, improving aerodynamic efficiency and power output. In addition, the high-precision machining capability of the five-axis CNC machine ensures the precise realization of complex geometric shapes, further enhancing the overall performance.

Everyone has heard that the efficiency of turbine blades machined by aluminum alloy CNC is better, but in fact, almost all turbine wheel seen on the market use general cast blades. In fact, the most important is the cost and technical considerations. The blades produced by casting method not only have low cost and fast manufacturing speed, but also can be produced in large quantities. However, the turbine made by using this blade is often in line with the general mass production needs, and the efficiency is enough for use in general occasions, but it can only be said that it is general, not too strong.

Forging CNC blades refers to the use of high-strength forged aluminum materials, through CNC (computer numerical control) processing technology to make turbine inlet side blades. Compared with ordinary cast aluminum alloy, forged aluminum has higher strength and better mechanical properties. However, this manufacturing method is not only expensive, but also technically difficult. Because the Angle and shape of the turbine blades are very complex, ordinary three – and four-axis CNC machines cannot accurately machine the complex geometry required. Therefore, more expensive and advanced five-axis CNC machines must be used to accomplish this task. The five-axis CNC machine enables multi-angle, high-precision machining, ensuring that every detail of the blade meets the design requirements.

In the past, the asking price of nearly 10 million five-axis CNC machinery is not only very expensive, and because it is the necessary machinery for manufacturing aerospace parts, military weapons and subject to government control, you must have the relevant industry background to introduce five-axis CNC. Therefore, there are not many manufacturers that have the ability and conditions to buy this kind of machine, even if the manufacturers of this kind of machine will not be specialized in manufacturing auto parts manufacturers, so in the past, the domestic almost will not add more ink on the turbine blade.

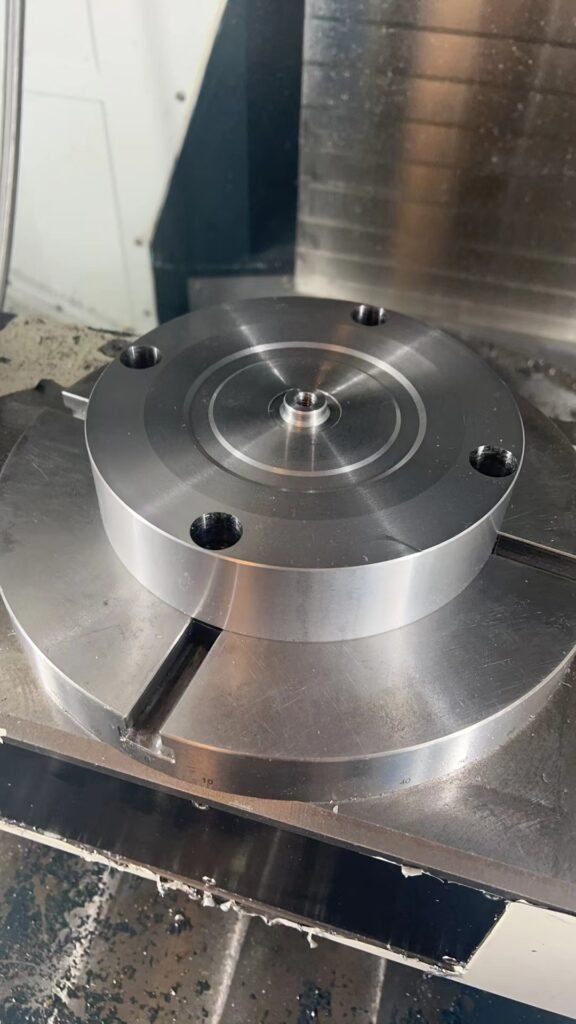

Precision machinery manufacturing is all about precision. Most of the general CNC tools are installed by lock, and the error is large when cutting. Here is a large purchase of special tool head and tool, the use of instantaneous high temperature heating to install the tool, so that the two closely engaged, so that the processing error will be smaller.Forging CNC blades from the Superalloy material to the finished product at least two hours of processing time, and it is no wonder that the price is quite high.

Our Shenzhen Blaze company has state-of-the-art CNC machining technology, which can efficiently and precisely process various turbine products. Not only do we have advanced five-axis CNC machines, but we can also accurately program and process according to complex turbine blade shapes. With our extensive experience and professional team, we are able to ensure machining accuracy and surface quality to meet various stringent industry standards. Whether it is high-strength forged aluminum or other special materials, we have professional processing solutions to provide customers with high-quality, efficient turbine products to help them achieve the best performance and reliability.

Thank you for your interest in our company! As a professional gas turbine parts manufacturing company, we will continue to be committed to technological innovation and service improvement, to provide more high-quality solutions for customers around the world.If you have any questions, suggestions or cooperation intentions, we are more than happy to help you. Please contact us in the following ways:

- WhatsAPP:+86 135 4409 5201

- E-mail:peter@turbineblade.net