In the realm of advanced engineering and manufacturing, the nozzle ring stands out as a vital component, particularly in industries such as aerospace, automotive, and power generation. This article delves into the significance of the nozzle ring, focusing on its design, function, and the choice of material—Inconel 718—which is renowned for its superior performance under extreme conditions.

The Role of the Nozzle Ring

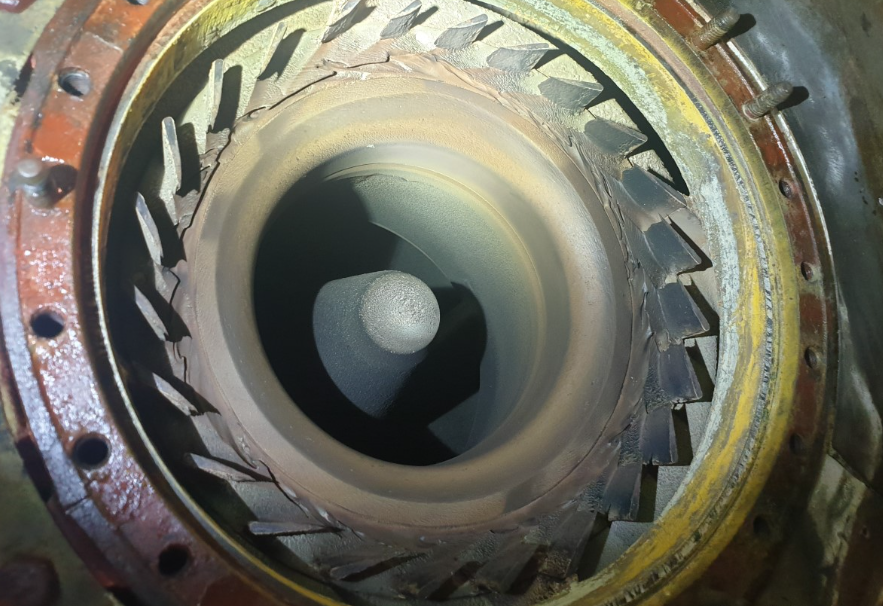

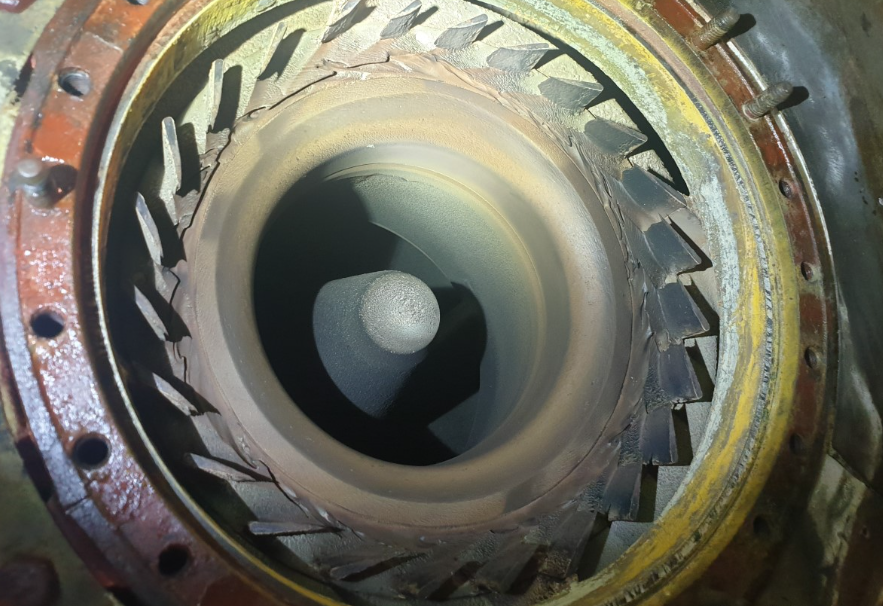

A nozzle ring is an essential part of various mechanical systems, including gas turbines, jet engines, and rocket propulsion systems. Its primary function is to guide and direct the flow of gases or fluids, optimizing the efficiency and performance of the system. In gas turbines, for example, the nozzle ring plays a crucial role in accelerating the exhaust gases, which in turn drives the turbine blades and generates power. Similarly, in aerospace applications, the nozzle ring helps to control the thrust and direction of the engine, ensuring stable and efficient operation during flight.

The design of a nozzle ring is intricate and requires precise engineering to ensure optimal performance. It typically consists of a series of vanes or blades arranged in a circular pattern, which guide the flow of gases or fluids. The shape and spacing of these vanes are carefully calculated to minimize turbulence and maximize the velocity of the exhaust gases. This precise control is essential for maintaining the efficiency and reliability of the entire system.

Material Selection: Inconel 718

When it comes to selecting materials for high-performance components like the nozzle ring, engineers must consider several factors, including strength, corrosion resistance, thermal stability, and manufacturability. Inconel 718 is a nickel-based superalloy that excels in these areas, making it a preferred choice for many critical applications.

Properties of Inconel 718:

- High Strength: Inconel 718 maintains its strength at elevated temperatures, up to 700°C (1300°F), which is crucial for components exposed to high-temperature environments. This property ensures that the nozzle ring can withstand the intense heat generated in gas turbines and jet engines without deforming or losing its structural integrity.

- Corrosion Resistance: It offers excellent resistance to both oxidizing and reducing environments, making it suitable for use in harsh chemical and marine conditions. This resistance is particularly important in aerospace and marine applications where exposure to corrosive agents is common.

- Thermal Stability: The alloy has a low coefficient of thermal expansion and excellent creep resistance, which ensures dimensional stability and reliability over time. This stability is crucial for maintaining the precise alignment and performance of the nozzle ring, especially in high-temperature and high-stress environments.

- Weldability: Inconel 718 can be easily welded using various techniques, facilitating repair and maintenance processes. This property is beneficial for extending the service life of the nozzle ring and reducing downtime for repairs.

- Formability: Despite its high strength, the alloy can be formed and machined, allowing for complex shapes and designs to be manufactured with precision. This formability is essential for creating the intricate vanes and structures required in a nozzle ring.

Manufacturing Process

The manufacturing of a nozzle ring from Inconel 718 involves several steps, each designed to ensure the highest quality and performance:

- Material Preparation: High-purity Inconel 718 ingots are sourced and inspected for any defects. The ingots are then processed through hot forging or extrusion to create the initial billets or bars. This step is critical for ensuring that the material is free from impurities and has a consistent grain structure.

- Machining: Precision machining is used to shape the billets into the desired geometry of the nozzle ring. This may include turning, milling, drilling, and grinding operations. Advanced CNC machines are often employed to achieve the tight tolerances required for high-performance components.

- Heat Treatment: To enhance the mechanical properties of the alloy, the nozzle ring undergoes heat treatment processes such as solution annealing and precipitation hardening. Solution annealing involves heating the component to a high temperature and then rapidly cooling it to dissolve any precipitates and homogenize the microstructure. Precipitation hardening involves reheating the component to a lower temperature to allow the formation of fine precipitates, which strengthen the material.

- Surface Finishing: The final step involves surface finishing to achieve the required smoothness and finish. Techniques such as polishing, coating, or plating may be applied to further enhance the performance and durability of the nozzle ring. Surface finishing not only improves the aesthetic appearance but also reduces friction and wear, contributing to the overall efficiency of the system.

Case Study: Aerospace Application

One notable example of the use of Inconel 718 nozzle rings is in the aerospace industry. A leading aerospace manufacturer recently integrated Inconel 718 nozzle rings into their latest generation of jet engines. The results were remarkable:

- Increased Efficiency: The nozzle rings significantly improved the efficiency of the engines by optimizing the flow of exhaust gases, leading to a 5% increase in fuel efficiency.

- Enhanced Reliability: The high strength and thermal stability of Inconel 718 ensured that the nozzle rings could operate reliably under the extreme conditions of high-altitude flight, reducing the risk of failures and extending the service life of the engines.

- Reduced Maintenance: The excellent corrosion resistance and formability of the material made it easier to manufacture and maintain the nozzle rings, reducing downtime and maintenance costs.

Conclusion

- The nozzle ring, when crafted from Inconel 718, represents a pinnacle of engineering excellence. Its combination of high strength, corrosion resistance, and thermal stability makes it indispensable in applications where performance and reliability are paramount. Whether in the skies, on the ground, or in industrial settings, the nozzle ring continues to play a critical role in advancing technology and pushing the boundaries of what is possible.

- For more information on Inconel 718 nozzle rings and other high-performance components, please contact our company at [Your Company Name]. We specialize in providing custom-engineered solutions for a wide range of industries, ensuring that your projects meet the highest standards of quality and performance.

- At BLAZE, we understand the importance of precision and reliability in high-performance components. Our team of experienced engineers and technicians is dedicated to delivering innovative solutions that meet the unique needs of our clients. From initial design to final production, we work closely with you to ensure that every aspect of the process is optimized for success.

- Whether you are looking to enhance the performance of your aerospace systems, improve the efficiency of your power generation equipment, or upgrade the reliability of your automotive components, we have the expertise and resources to help you achieve your goals. Contact us today to learn more about how we can support your engineering projects and help you achieve excellence in your industry.