As a key component of gas-dynamic energy conversion, the dimensional accuracy of turbine blades is not only related to whether the gas turbine can be installed smoothly, but also the key to ensure its safe operation. Turbine blade parts are complex spatial surfaces with uneven thickness, and the process of indefinite investment precision casting is complicated, in which each stage has an impact on the dimensional accuracy of the final blade, and it is difficult to take into account the geometrical characteristics of blade bending and torsion deformation and blade curvature only by relying on the method of mold surface reduction. During the process from the wax mold to the blade casting, not only the volume shrinkage will occur, but also the geometric characteristics will change to a certain extent, which will cause the size of the casting to be out of alignment. Therefore, in the actual production process, each link of turbine blade manufacturing needs to be accurately measured and controlled. As early as the 1970s, the United Kingdom and the United States have achieved remarkable results in the control technology of the core, and are used for casting. In recent years, optical scanners and industrial tomogrophy (CT) computerized measurement of a gas turbine engine blade in foreign countries require the blade measurement accuracy to be controlled within 50 to 80μμm, and the allowable tolerance is controlled within±±0.5 mm. Moreover, through registration with CAD model, the distortion and deformation of each part of the blade can be directly reflected [51-52].

Due to the critical role of blades and the difficulty of manufacturing technology, turbine blade shape control is regarded as a highly core technology in foreign countries, and its research results are rarely disclosed. The testing technology of gas turbine engine blade in China is still in a developing process. In terms of testing technology standards, the domestic aviation industry standards for reference are only HB5647-98 and HB20126-201. Therefore, some domestic manufacturers and research institutions have put forward their own testing and acceptance technical requirements for internal acceptance, which is convenient for application management. In this process, they combined with foreign measurement technology means, and according to whether the measurement device is in contact with the measured object, the measurement method of gas turbine engine blade is divided into contact and non-contact. The contact measuring methods mainly include: standard template measuring method, inductance measuring method and three coordinate measuring method. Non-contact measurement methods mainly include: laser scanning measurement, ultrasonic detection, machine vision measurement and industrial CT measurement [53]. In addition, at present, some researchers have carried out research on blade size control based on numerical simulation, and error accumulation and transmission based on big data and numerical simulation has become an important method for future development.

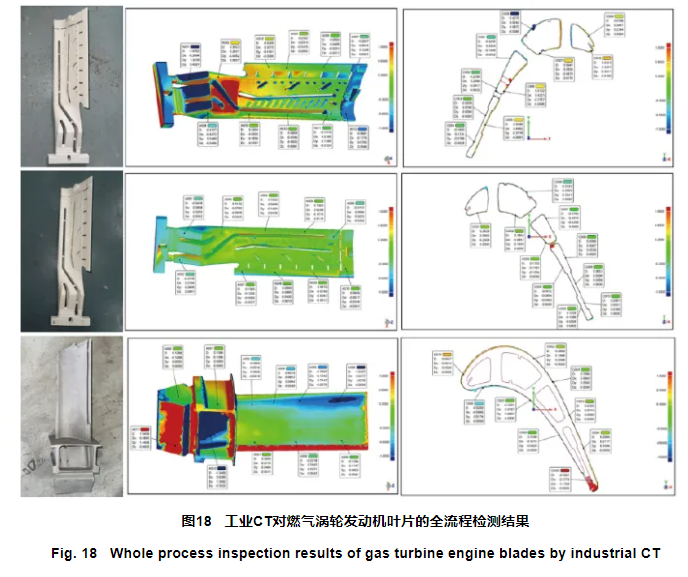

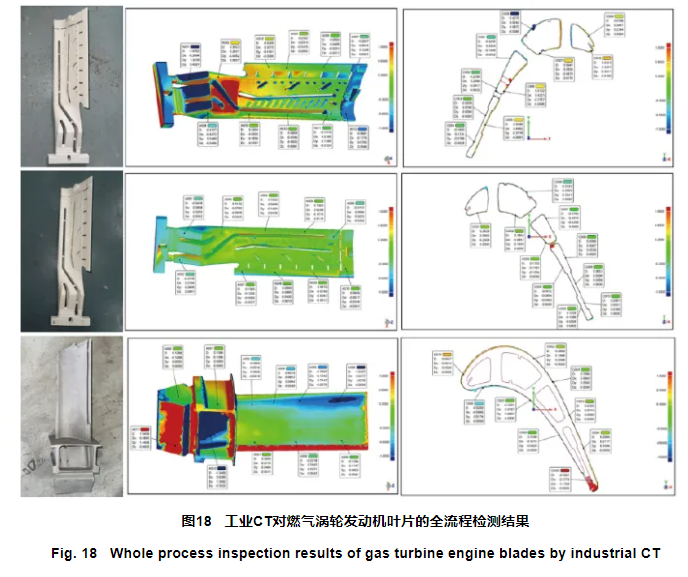

Based on the structural characteristics and casting process characteristics of gas turbine cylindrical/single crystal turbine blades, dimensional accuracy control of the whole process of precision casting is the key to improve the qualified rate of blade size. Based on this, this research group adopts 3D laser scanning measurement method and industrial CT measurement method, combined with three-dimensional coordinate and ultrasonic detection methods, to conduct defect detection and size measurement for the preparation process of the whole process of gas turbine engine blades (wax mold blank, core blank, ceramic core, wax press core, mold shell with wax, mold shell without wax, casting). The dimensional accuracy and error control model of the whole process of turbine blade preparation were established.

FIG. 18 shows the analysis of blade size measurement results of key aspects such as the blank, core and casting of large-size turbine blades of a certain type of gas turbine developed by us. For castings, refer to DCPG5 in GB/T 6414−−2017, the allowable tolerance is±±0.5mm, and the measurement accuracy is required to be controlled at 120μμm; The allowable tolerance of the ceramic core is±±0.3mm, and the measurement accuracy is required to be controlled at 80μμ

m. In the blade development process, dimensional accuracy control will be performed for all the prepared blades in the whole process, and dimensional accuracy and errors in the blank, core and casting stages during the blade preparation process of gas turbine engine will be analyzed with the help of reverse verification software Geomajic-Control or GOM. The dimensional deviation and deformation law of the whole process of blade preparation were preliminarily revealed. The results show that the non-destructive measurement methods such as 3D laser scanning, industrial CT and ultrasonic testing can meet the measurement accuracy requirements of a certain type of gas turbine engine blade. Three-dimensional laser scanning measurement method can obtain the outline of the key intermediate components such as the blade, wax mold and ceramic core of the gas turbine engine, and can accurately evaluate the torsional deformation of the blade. Industrial CT can not only detect the internal defects of ceramic core, wax mold and mold shell, but also measure the contour, inner cavity structure, wall thickness and other key parts with high precision. Ultrasonic inspection can accurately measure the wall thickness structure of wax mold and blade. These advanced measurement methods ensure the size measurement and accurate control of the whole process of large-size turbine blades, especially the size measurement of the mold shell based on industrial CT detection technology, which can extract the inner cavity structure of the mold shell and compare it with the model, thus realizing the accurate measurement of the mold shell size, which is impossible to achieve with traditional measurement methods.

At present, the testing methods that are gradually mature and put into the engineering application of gas turbine engine blades greatly shorten the development cycle of blades, improve the qualified rate of blade size, and reduce the cost of blades. However, regarding gas turbine engine blades, there are still the following deficiencies: incomplete technical specifications and standard system for blade testing, lack of effective technical verification means, insufficient data accumulation related to dimensional change and error accumulation during blade preparation, and lack of self-developed blade size measurement and analysis software. With the wide application of computer technology in the field of blade manufacturing, intelligent manufacturing technology based on machine learning and numerical simulation will also play an important role in the error control of the whole process of the blade, so as to improve the size control accuracy of the blade.