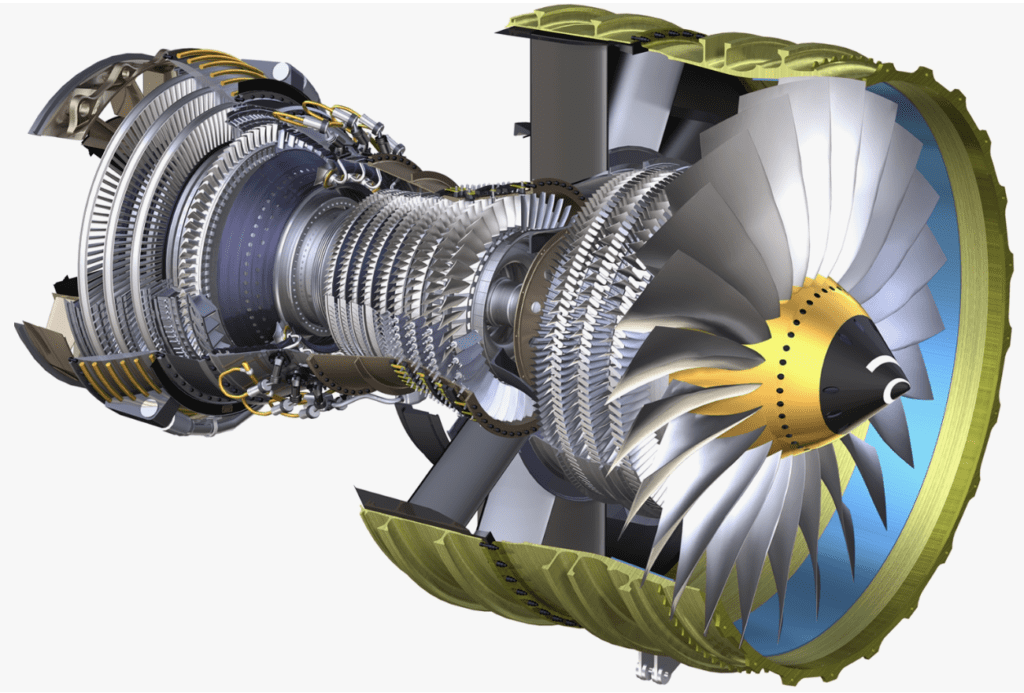

Turbine blades are critical components in modern industrial and aerospace engines, and those made from Inconel 600 are becoming the preferred solution due to their exceptional heat resistance and corrosion resistance. As technology advances and the demand for high-performance materials increases, Inconel 600 stands out with its unique properties in a wide range of applications.

Overview of Inconel 600 Properties

Inconel 600 is a nickel-based alloy containing chromium (Cr) and iron (Fe), known for its excellent high-temperature, oxidation, and corrosion resistance. This material can maintain good mechanical properties at temperatures up to 1093°C (2000°F) and resist various corrosive media, such as saltwater, organic acids, and alkaline solutions. Additionally, Inconel 600 has superior weldability and formability, making it an ideal choice for manufacturing complex-shaped parts. The alloy’s ability to withstand repeated thermal cycling without significant degradation further enhances its suitability for high-temperature applications.

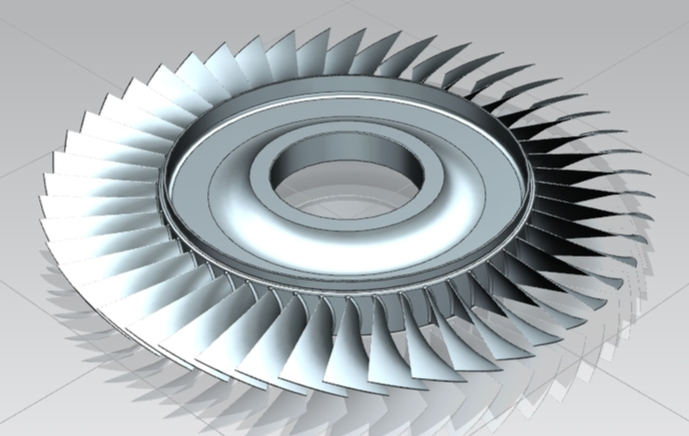

Design Considerations for Turbine Blades

- When designing turbine blades, several factors must be considered, including thermal efficiency, mechanical strength, durability, and maintenance costs. Using Inconel 600 can significantly enhance the overall performance of the blades. Due to its excellent heat resistance, this material allows for more efficient energy conversion processes, thereby improving the overall system’s energy efficiency. Moreover, the high toughness and wear resistance of Inconel 600 reduce maintenance frequency, extend component life, and lower long-term operational costs. For companies striving for sustainability, choosing such a material helps reduce resource consumption and minimize environmental impact.

- In addition to these properties, Inconel 600 also offers excellent creep resistance, which is crucial in high-temperature environments where materials are subjected to prolonged stress. This property ensures that the blades maintain their structural integrity over extended periods, even under extreme conditions.

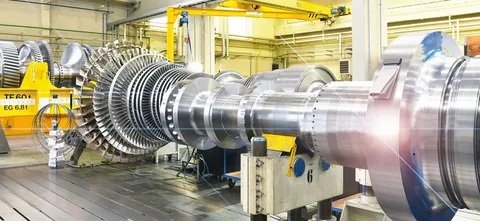

Real-World Applications

- Many leading industrial manufacturers have adopted Inconel 600 to optimize their turbine blade product lines. For example, in a large power plant project, key blade components made from Inconel 600 not only achieved higher operating temperature ranges but also promoted cleaner combustion processes and effectively reduced harmful emissions. This not only improves the efficiency of the power plant but also contributes to a more sustainable and environmentally friendly operation.

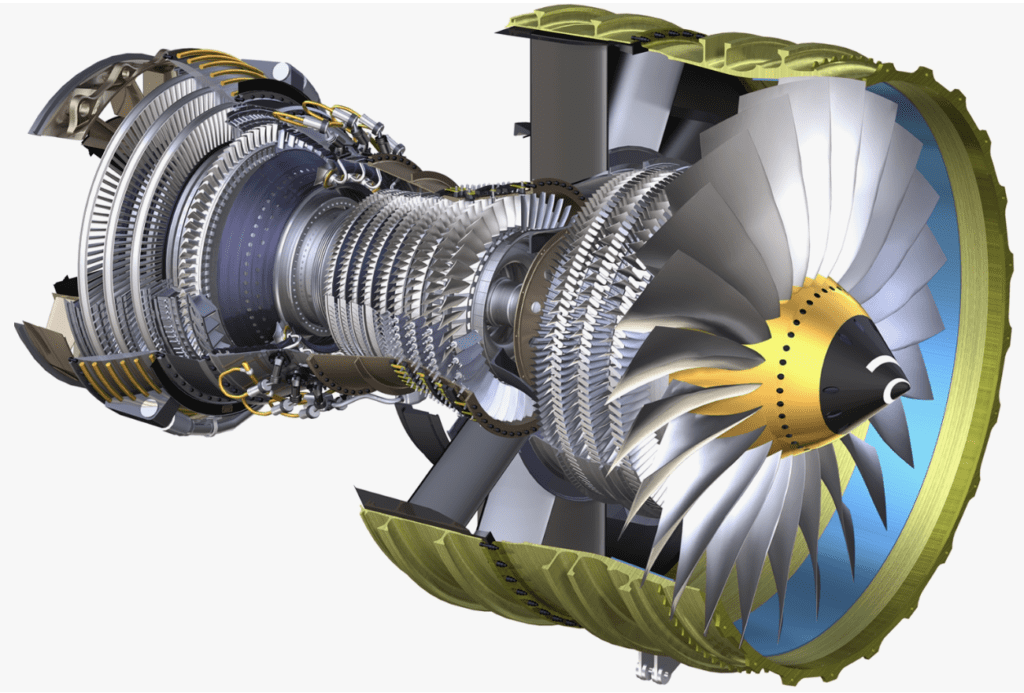

- In the aerospace industry, some advanced engine manufacturers are exploring the use of Inconel 600 in the design of new, highly efficient, and environmentally friendly engines. These engines are designed to meet increasingly stringent environmental standards, such as reduced NOx and CO2 emissions, while maintaining or even improving performance. The use of Inconel 600 in these applications ensures that the engines can operate efficiently at high temperatures, contributing to better fuel economy and lower emissions.

- In practical operations, turbine blades made from Inconel 600 have demonstrated superior durability and reliability. In a multi-year continuous operation test, blades made from Inconel 600 showed extremely low failure rates, proving their stability under harsh conditions. The application of this material not only enhances the safety and lifespan of equipment but also reduces maintenance costs, significantly improving overall economic benefits.

Technological Innovations and Future Outlook

- As material science progresses, researchers are continuously seeking ways to further improve the performance of Inconel 600. For instance, by fine-tuning the alloy composition or using new manufacturing processes to enhance specific properties. These efforts aim to develop more cost-effective and higher-performing next-generation high-temperature alloys to better serve future energy industries. It is expected that in the coming years, we will see more applications of Inconel 600 and its derivatives, driving related industries to higher levels of performance.

- In addition to material innovations, manufacturing techniques and quality control methods are also evolving. For example, additive manufacturing (3D printing) is being used to produce complex Inconel 600 parts, which not only shortens production cycles but also enables designs that are difficult to achieve with traditional manufacturing. Advanced inspection technologies, such as X-ray computed tomography (CT), are also being employed to ensure that each component meets the most stringent quality standards.

- Furthermore, the integration of digital twin technology and predictive maintenance systems is enhancing the lifecycle management of turbine blades. By using real-time data and advanced analytics, operators can monitor the condition of the blades and predict potential failures, allowing for proactive maintenance and reducing downtime.

Conclusion

In summary, Inconel 600, with its unique physical and chemical properties, holds a significant position in the manufacture of turbine blades. For companies seeking innovation and aiming to provide the best performance solutions, choosing Inconel 600 is undoubtedly a wise decision. As technology continues to advance, this material will continue to play a crucial role in supporting the global transition to cleaner and more efficient energy systems.

Contact Us

If you are interested in our Inconel 600 turbine blades or have any questions, please feel free to contact us. Our professional team will be happy to provide detailed information and tailor suitable solutions based on your specific needs. We are committed to providing high-quality products and services to help you achieve your business goals. We look forward to collaborating with you to create a brighter future!