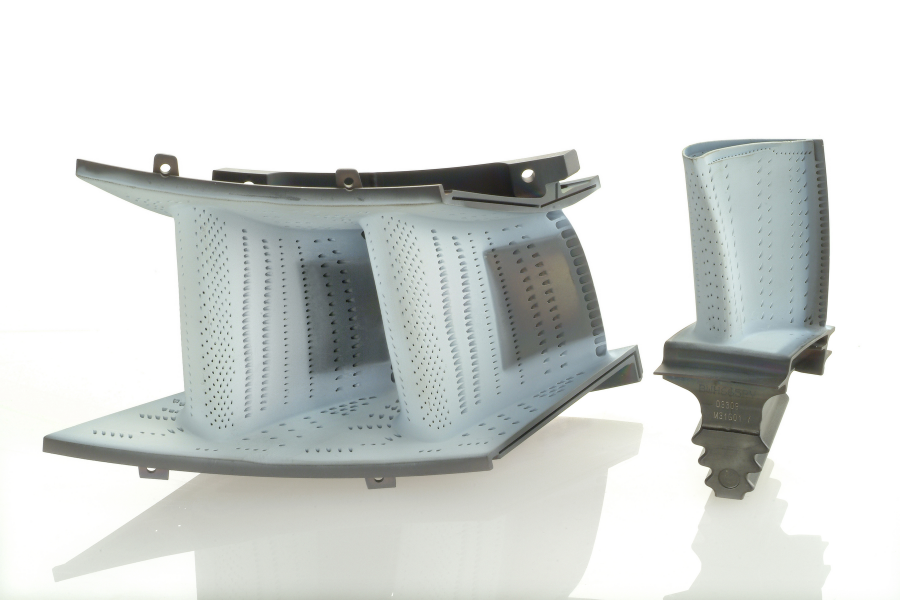

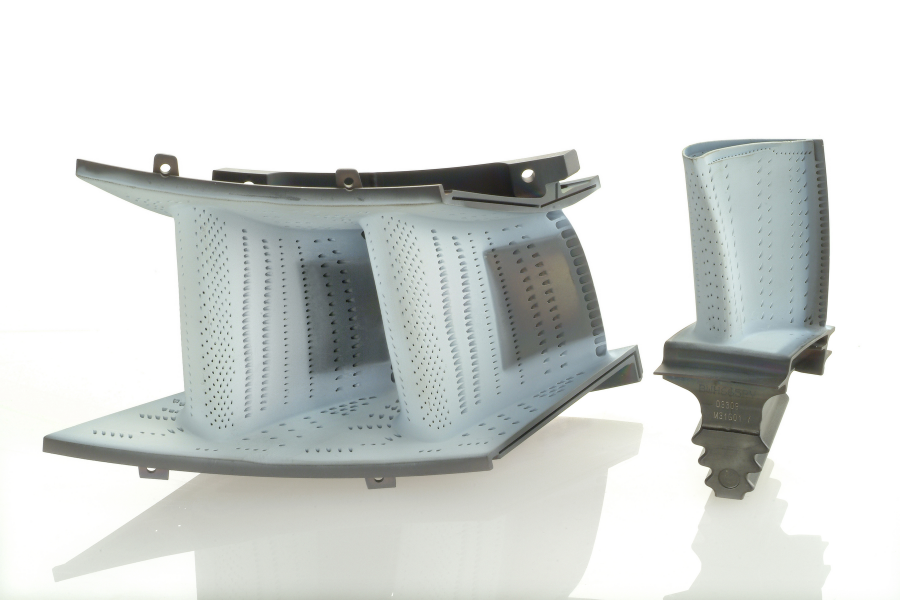

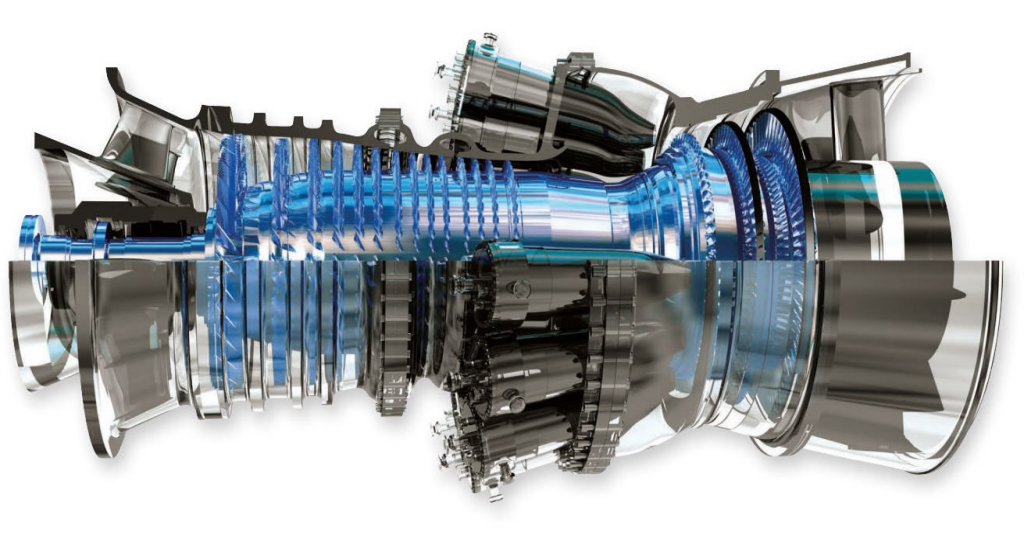

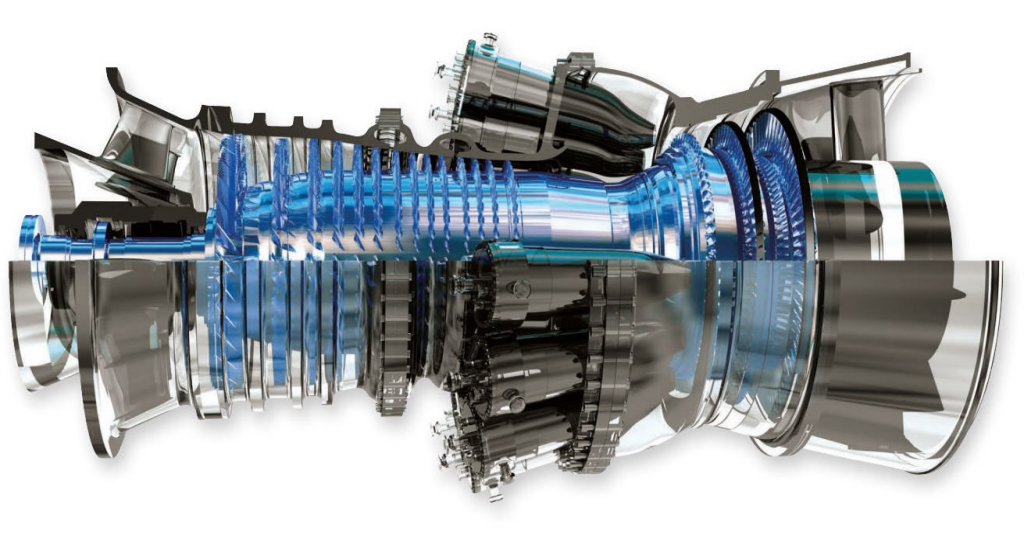

We BLAZE is a company specializing in the customization and reverse research and development of superalloy turbine accessories. We have rich experience and advanced production equipment, as well as a professional R & D team, committed to providing customers with a variety of superalloy accessories production services, the most production of turbine blades, turbine wheel, guide blades, nozzle rings, rotor stators and combustion chambers, etc. For every turbine accessory, we have a lot of experience.

1. Material introduction

This time we want to introduce our commonly used Inconel 738 material, which is a kind of superalloy, widely used in aerospace industry, energy industry and other high temperature and high pressure environment, in the customer’s feedback, our InCONEL 738 turbine accessories in use has very high quality heat resistance, corrosion resistance and mechanical use. Suitable for all kinds of special environment.

2. Technological advantages

(1) Precision casting and heat treatment

According to the customer’s choice and use scenario, we have formulated the use of vacuum melting and directional solidification technology to ensure that the material will not be too affected, so as to ensure the material and wear accuracy and uniformity. High precision mold design and manufacturing allows us to achieve precise molding of complex geometrics and strict control of dimensions to meet the highest standards. Our heat treatment process is further optimized to improve the strength and toughness of the material. After heat treatment, we carry out cooling, and after accurately controlling the cold and heat treatment, we ensure consistent mechanical properties, eliminate stress, reduce internal stress, and improve the service life of the parts.

(2) Surface treatment and quality control

In terms of surface treatment, we choose sandblasting, polishing and high performance coatings to meet the needs of different use cases. The anti-oxidation and anti-corrosion coatings further enhance the durability of turbine accessories in a variety of special environments. After surface treatment and treatment, we carry out quality control on the full name of the products produced, from the selection of materials to the inspection of the finished products, every link has carried out strict quality control. In the quality inspection, we use X-ray inspection, ultrasonic inspection, etc., to ensure that there are no defects inside and outside. Our production processes and quality comply with international standards such as ISO 9001 and AS9100, ensuring product reliability and consistency.

3. Customized services

- Personalized design: According to the specific needs of customers, provide professional design support to ensure that the product fully meets the application requirements.

- Rapid prototyping: Use advanced technologies such as 3D printing to quickly produce samples and shorten the development cycle.

- Flexible production scale: We respond efficiently and deliver on time, whether it is a small batch or a large batch.

- Comprehensive technical support: Our technical team will support you from material selection to final installation.

4. Application field

Aero engines, gas turbines, industrial burners, petrochemical equipment, other high temperature and high pressure environments

5.Why choose us?

- Rich industry experience : Many years of Inconel 738 processing experience, accumulated deep technical accumulation.

- Advanced production equipment : The introduction of international advanced production and testing equipment to ensure product quality.

- Strict quality control : From raw materials to finished products, every step goes through strict quality control.

- Professional technical support : Experienced team of engineers, ready to solve technical problems for you.

- Responsive service : Efficient customer service team to ensure timely communication and problem resolution.

Thank you for your interest in our company! As a professional gas turbine parts manufacturing company, we will continue to be committed to technological innovation and service improvement, to provide more high-quality solutions for customers around the world.If you have any questions, suggestions or cooperation intentions, we are more than happy to help you. Please contact us in the following ways:

- WhatsAPP:+86 135 4409 5201

- E-mail:peter@turbineblade.net