Advances in turbine blade technology have increased the cost of new components. The cost of a single crystal blade is two to three times that of a conventional cast blade of similar size and complexity. The high cost of a single crystal component can incentivize the owner to maximize the service life of the component.

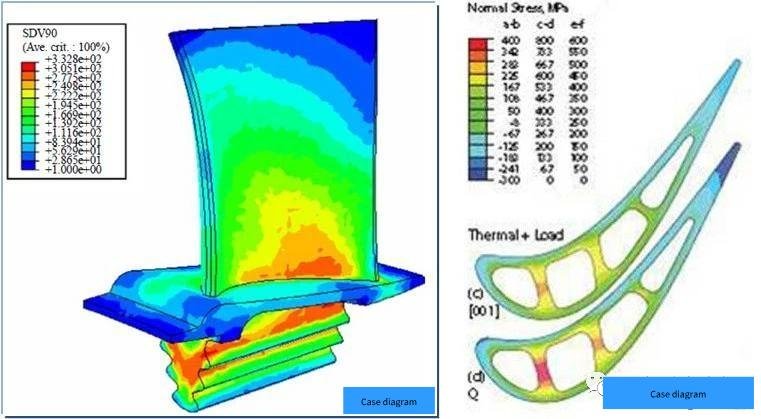

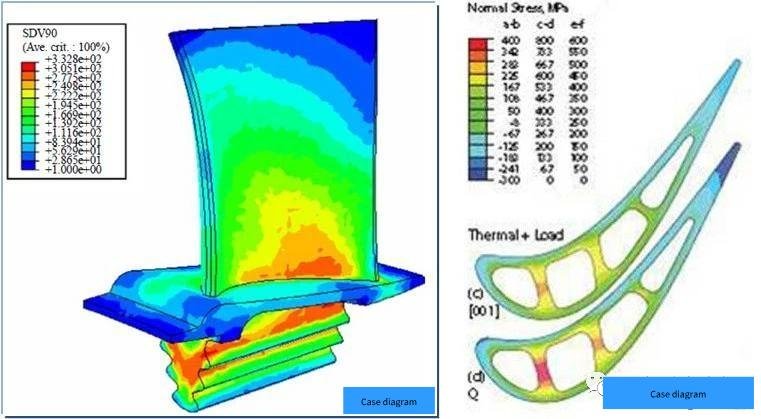

As a solution to reduce the cost of replacing components, our company has created processes designed to extend the life of components. One such process is full solution regenerative heat treatment (FSR). FSR restores the microstructure and mechanical properties of the alloy to a new state. The main problem of heat treatment of single crystal alloy FSR is the formation of recrystallized grains on the surface with residual stress. This is a risk given the low content of grain boundary strengthening alloy additives in single crystal alloys. Recrystallization and/or stray grains in single crystal alloys result in reduced fatigue life and stress break strength at high temperatures. As a result, they are inspected by the original manufacturer and rejected. This is one of the factors for the price rise of single crystal castings!

Our companyconducted a trial repair to further evaluate the feasibility of FSR heat treatment of single crystal turbine blades, during which it was crucial to ensure that the critical surfaces of the blades did not undergo plastic deformation to avoid subsequent recrystallization. In addition, it is necessary to use effective non-destructive testing methods to check the recrystallization of critical surfaces. Demonstration repair and destructive analysis were performed using a retired Siemens SGT-100 HP turbine blade composed of CMSX-4 single crystal alloy, as shown in Figure 2. The blades were in operation for 28,000 hours. After one repair, it operated for another 12,000 hours. Total service time is 36,000 hours and the OEM notifies the operator that the part has expired!

A representative blade in the group was subjected to a destructive inspection in the “when received” state to establish a baseline of metallurgical conditions. The remaining five blades are in need of repair, including:

- Removal of coating

- Size and penetration detection

- Full solution rejuvenation heat treatment

- Replace external platinum-aluminate coating

A representative blade in the group was subjected to a destructive inspection in the “when received” state to establish a baseline of metallurgical conditions. The remaining five blades are in need of repair, including:

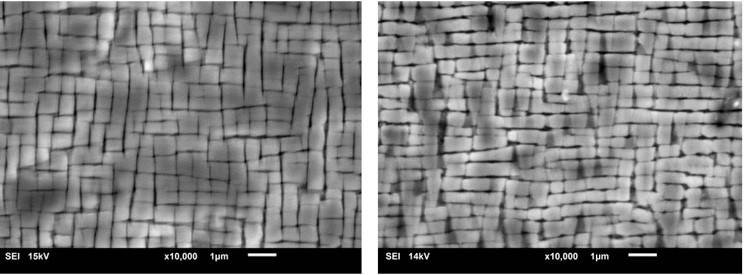

- Scanning electron microscopy of base alloys (gamma form)

- Stress fracture testing of microplate samples taken from airfoils

- Microscopic examination of internal and external surfaces.

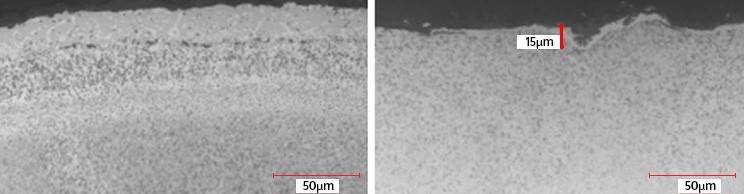

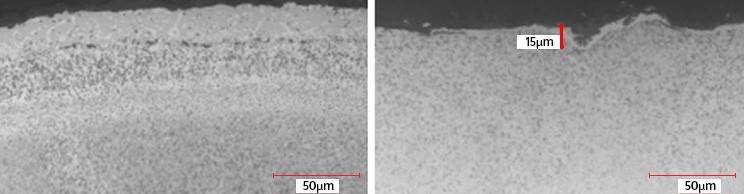

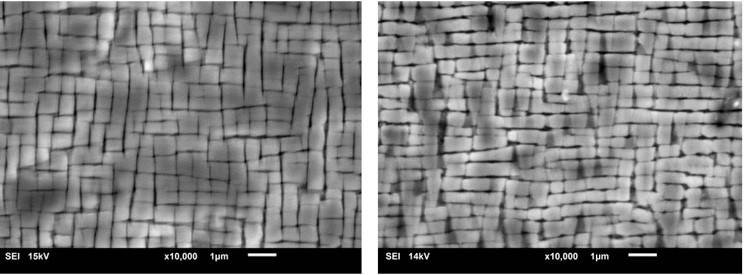

The outer surface of the airfoil contains an aluminized platinum coating, as shown in Figure . Although the coating was partially consumed, it provided effective protection for previous service intervals, as no damage to the underlying base alloy was observed.

Internal airfoil surface uncoated, Figure 3 right. Slight oxidation of the base alloy was observed on the inner surface with a penetration depth of <25 microns (0.001 in).

After the coating is removed, the leaves are checked for surface exposed cracks or defects by fluorescent penetration testing (FPI). No signs were found.

The examination determined that these leaves were good objects for repair. Ultrasonic technology is used to measure the wall thickness.

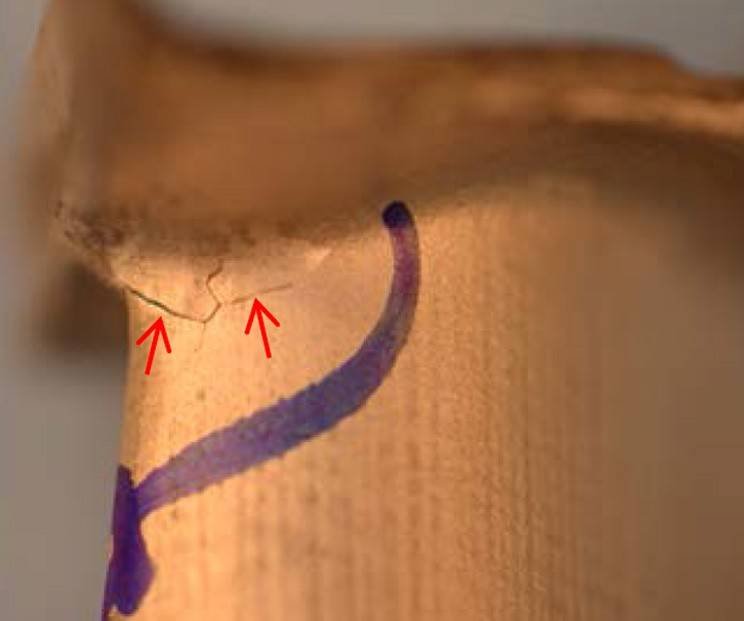

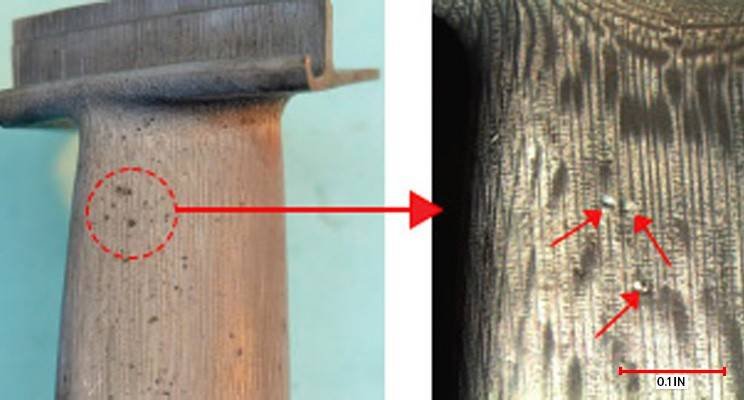

After FSR heat treatment, the recrystallized grains in the key areas of the blades were nondestructively examined by chemical etching. In four of the five blades, recrystallized grains appear in key regions (example shown in Figure 4).

Destructive inspection confirmed that the recrystallization depth of at least one blade exceeded the usable limit (not all recrystallization areas were destructised).

Based on this finding, another 12 end-of-life blades were submitted for further analysis. The group consists of seven blades from the same initial test group of six blades and five blades from different blade groups. All blades were repaired, including coating removal and an FSR heat treatment process, followed by a macroscopic etching inspection of the recrystallized grains.

All the leaves initially had some recrystallized grains to varying degrees in the key regions. The blade undergoes a cycle of mechanical grain removal and re-inspection until the recrystallized grains are eliminated from all critical areas. Finally, a destructive inspection of the eight blades (five in a group of seven and three in a group of five) was performed to verify the inspection results and assess the remaining wall thickness. All seven blades of the first group were found to be within maintenance limits, and four-fifths of the blades of the second group were found to be within maintenance limits.

Thank you for your interest in our company! As a professional gas turbine parts manufacturing company, we will continue to be committed to technological innovation and service improvement, to provide more high-quality solutions for customers around the world.If you have any questions, suggestions or cooperation intentions, we are more than happy to help you. Please contact us in the following ways:

- WhatsAPP:+86 135 4409 5201

- E-mail:peter@turbineblade.net