Directional Solidification technology is an advanced casting method used to manufacture turbine blades, aiming to improve the mechanical properties and high-temperature performance of the blades by controlling the grain growth direction. This technology has an important place in turbine blade manufacturing, especially in high-performance applications such as aerospace engines and gas turbines.

Directional Solidification technology is an advanced casting method used to manufacture turbine blades, aiming to improve the mechanical properties and high-temperature performance of the blades by controlling the grain growth direction. This technology has an important place in turbine blade manufacturing, especially in high-performance applications such as aerospace engines and gas turbines.

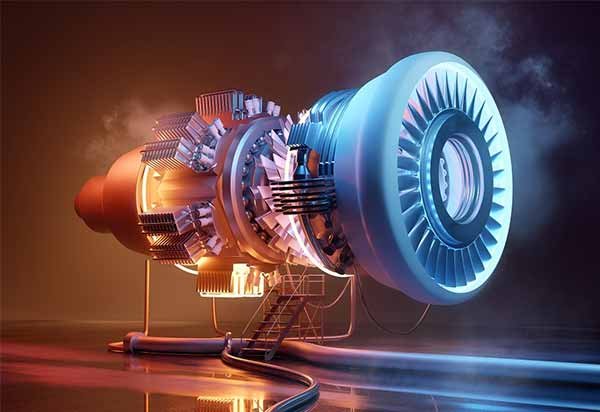

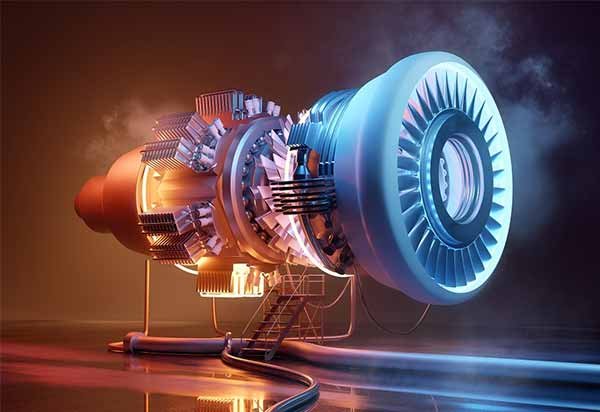

Turbine blades are an important component of the turbine section of a gas turbine engine. The high-speed rotating blades are responsible for sucking high-temperature and high-pressure airflow into the burner to maintain the engine’s operation. In order to ensure stable operation for a long time in extreme environments of high temperature and pressure, turbine blades are often forged from high-temperature alloys and cooled using different methods, such as internal airflow cooling, boundary layer cooling, or thermal barrier coatings to protect the blades. Ensure operational reliability.

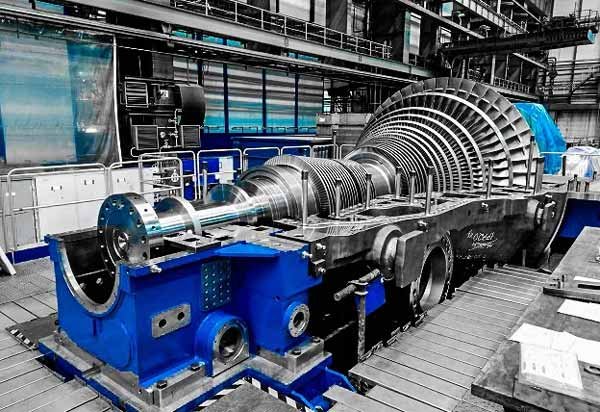

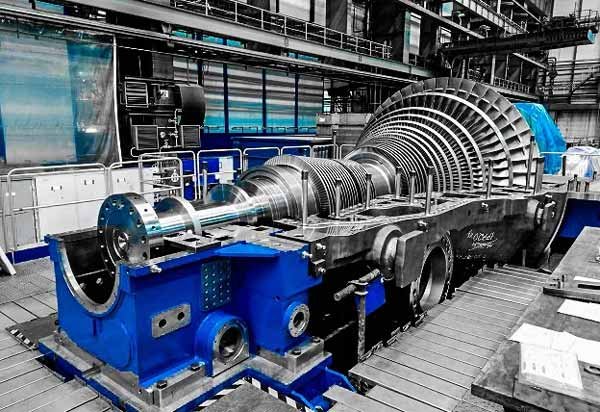

In steam turbine engines and gas turbine engines, metal fatigue of blades is the main cause of engine failure. Strong vibration or resonance may cause metal fatigue. Engineers often use friction dampers to reduce damage to blades caused by these factors.

The grain structure of directional casting is arranged along the longitudinal direction of the blade, reducing the number of grain boundaries, thus improving the strength and creep resistance of the blade at high temperatures.

The oriented grain structure can better withstand thermal stress and cyclic thermal load, extending the service life of the blade.

It reduces the number of grain boundaries and potential paths for corrosion and oxidation, improving the material's tolerance in high-temperature corrosive environments.

The oriented grain structure improves the comprehensive mechanical properties of the blade, including tensile strength, ductility and toughness.

Make high-precision ceramic molds with precise internal design to ensure that the shape and size of the casting meet the design requirements.

Melt the high-temperature alloys (such as nickel-based alloys) required for turbine blades and keep them in a liquid state.

1. Bottom cooling: A cooling device is installed at the bottom of the mold to allow the liquid metal to solidify from the bottom.

2. Upper heating: The upper part of the mold is kept at a higher temperature to ensure that the crystallization direction is gradually solidified from bottom to top.

By controlling the cooling rate and temperature gradient, the grains are induced to grow along a specific direction (usually the vertical direction) to form a directional grain structure.

After casting is completed, the blades are heat treated to optimize the grain structure and material properties.

Castings are deburred, polished and precision machined to achieve final size and surface quality requirements.

Pour the molten metal into the preheated ceramic mold.

The high-pressure turbine blades of high-performance aeroengines are required to maintain stable performance under extremely high temperatures and stress.

Gas turbine used for power generation and industrial drives, especially operating in high temperature and high pressure environments.

Turbine machinery used in spacecraft requires extremely high reliability and performance.

Directional casting technology is an advanced casting method that has a positive impact on the physical and chemical properties of turbine blades. Specifically, this technology mainly affects the strength, heat resistance and corrosion resistance of turbine blades. This is mainly due to the following aspects

Inconel (nickel-based high-temperature alloy)

Material characteristics: Inconel alloy has excellent high temperature strength, corrosion resistance and creep resistance.

Directional casting applicability: Inconel alloys can be suitable for directional casting processes, especially alloys specifically designed for directional casting such as Inconel 738 and Inconel 792. These alloys have excellent properties in high temperature environments and are suitable for manufacturing high temperature turbine blades.

Nimonic (nickel-based high-temperature alloy)

Material characteristics: Nimonic alloy has excellent high-temperature strength and creep resistance and is widely used in aerospace engines.

Directional casting applicability: Nimonic alloys can be suitable for directional casting processes, especially alloys such as Nimonic 105 and Nimonic 263 that are specially designed for directional casting. These alloys have excellent properties in high temperature environments and are suitable for manufacturing high temperature turbine blades.

Single Crystal Materials

Material characteristics: Single crystal materials have a grain boundary-free structure, eliminating weaknesses at grain boundaries, and have excellent high-temperature strength and creep resistance.

Directional casting applicability: Single crystal materials are specially designed for directional casting processes and are widely used in the manufacture of high-temperature turbine blades. These materials are usually nickel-based high-temperature alloys such as CMSX-4, PWA 1484, and Rene N5.

Part numbers alone are not sufficient to ensure performance.

To guarantee precision and compatibility, please provide:

Drawings or used samples for reverse engineering.