Monel turbine parts have excellent corrosion resistance, especially in seawater and other harsh chemical environments. It also has good strength and toughness to withstand the pressure and stress of turbine operation. Monel alloy has good thermal stability and can maintain stable performance within a certain temperature range.

Monel 400 is the most common Monel alloy, and its general maximum use temperature is about 540°C (1000°F).

In practical applications, it is usually recommended to use it below 300°C (570°F) to ensure the performance and life of the alloy.

Monel K-500 has higher strength and hardness than Monel 400, but its maximum use temperature is roughly the same, about 550°C (1020°F).

Turbine accessories are widely used in various turbines, including:

Aerospace engines: Turbine accessories are the core components of aircraft engines, responsible for converting the energy of gas into mechanical energy and driving the rotation of the engine.

Industrial gas turbines: Used for power generation and mechanical drive, turbine accessories work in high temperature and high pressure environments, requiring excellent high temperature performance and reliability.

Steam turbines: Used for power generation and industrial drive, turbine accessories convert the energy of high temperature and high pressure steam into mechanical energy.

Turbocharger: Used to increase the intake pressure of an internal combustion engine, the turbine accessory converts the energy of the exhaust gas into mechanical energy to drive the compressor.

The main function of the spring in a high-temperature turbine engine is to provide mechanical compensation and vibration absorption. High-temperature alloy springs can work for a long time in a high-temperature, high-stress environment, and have good heat resistance and fatigue life. They are widely used in the connection and support of various components.

The stator is the stationary part of the turbine engine, which plays a guiding and supporting role. The stator blades are fixed to the turbine casing to change the direction of the airflow and increase the kinetic energy of the gas. The stator made of high-temperature alloys can maintain a stable state under high temperature and high pressure environments, reducing deformation and fatigue damage.

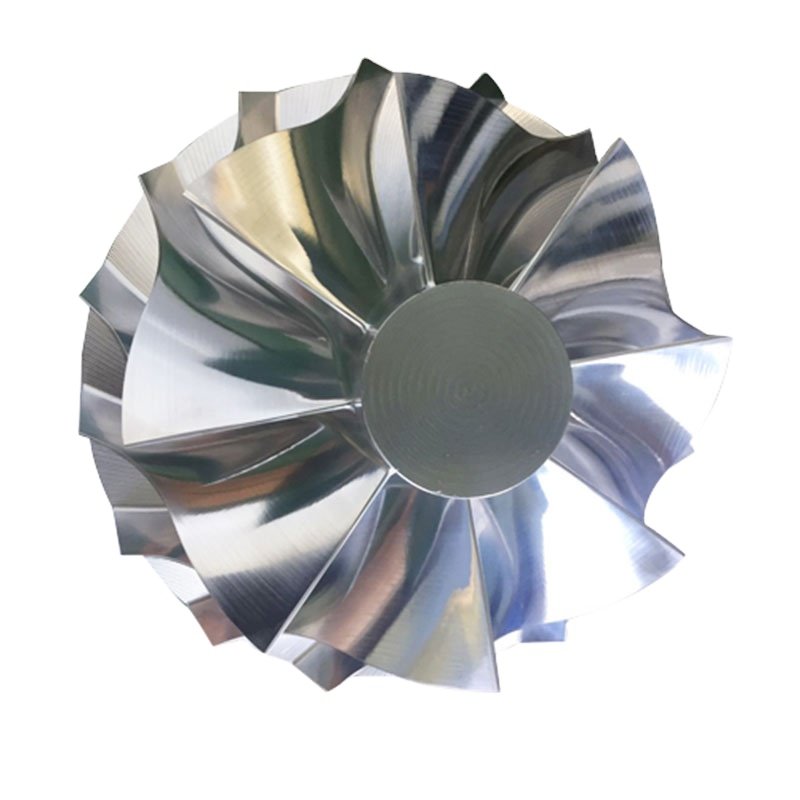

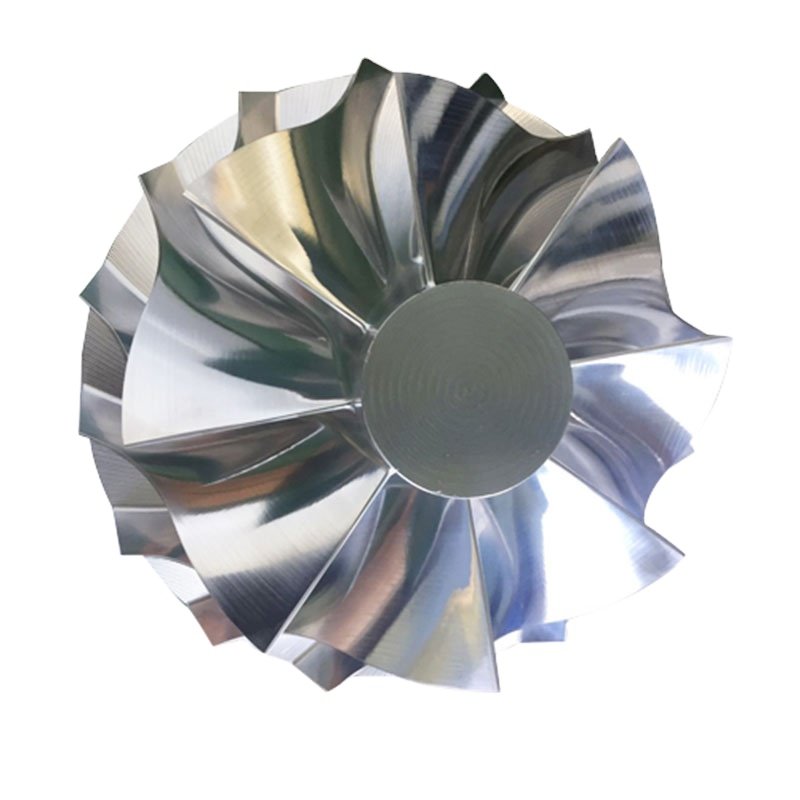

The rotor is a rotating part in a turbine engine that converts the kinetic energy of the gas into mechanical energy, thereby driving the axle and other components. The rotor blades need to operate at high speed and high temperature and high pressure, so they are usually made of high-temperature alloys to ensure their strength and durability and reduce wear and cracks during operation.

The combustion chamber is one of the core components of the engine, used for mixing and burning fuel and compressed air. High-temperature alloy combustion chambers can withstand extremely high temperatures and pressures, providing the turbine blades with the required high-energy gases while reducing combustion erosion on the metal structure.

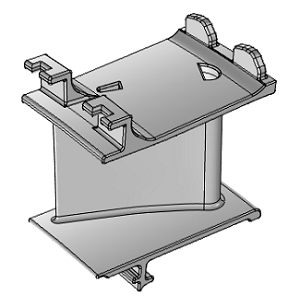

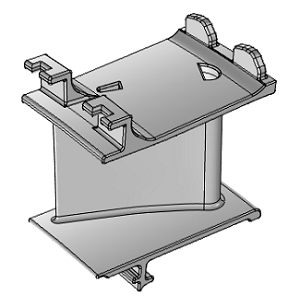

Arc segments are part of the turbine's interior, usually near the impeller passage. They are made of high-temperature alloys to adjust and support the airflow, and work under high temperature and high pressure conditions to ensure the stability and efficiency of the turbine operation.

Guide vanes are fixed to the stator to guide the airflow entering the rotor. High-temperature alloy guide vanes can work efficiently in extreme environments, have high corrosion resistance and strength, and ensure accurate and stable airflow direction adjustment.

The nozzle ring is used to guide the combustion gas into the turbine to maximize energy conversion efficiency. High-temperature alloy nozzle rings have excellent heat resistance and oxidation resistance, ensuring that the structure does not deform under high temperature and high pressure conditions, extending the service life.

Swirler are used to enhance and maintain the turbulent state of the airflow and improve combustion efficiency. High-temperature alloy swirler have excellent thermal fatigue resistance and can work for a long time in harsh working environments to ensure complete and efficient combustion.

The diffuser is located at the rear of the turbine and is used to slow down and increase the airflow pressure. High-temperature alloy diffusers are designed to withstand the high-temperature and high-pressure airflow from the turbine, thereby ensuring efficient operation of the engine and reducing fatigue and damage.

Bolts and nuts play a role in fastening and connecting in high-temperature turbine engines. High-temperature alloy bolts and nuts can maintain high strength and stability under high temperature and high pressure environments, prevent loosening and connection failure caused by thermal expansion, ensure that each component is tightly combined, and maintain the overall performance and safety of the engine.

Part numbers alone are not sufficient to ensure performance.

To guarantee precision and compatibility, please provide:

Drawings or used samples for reverse engineering.