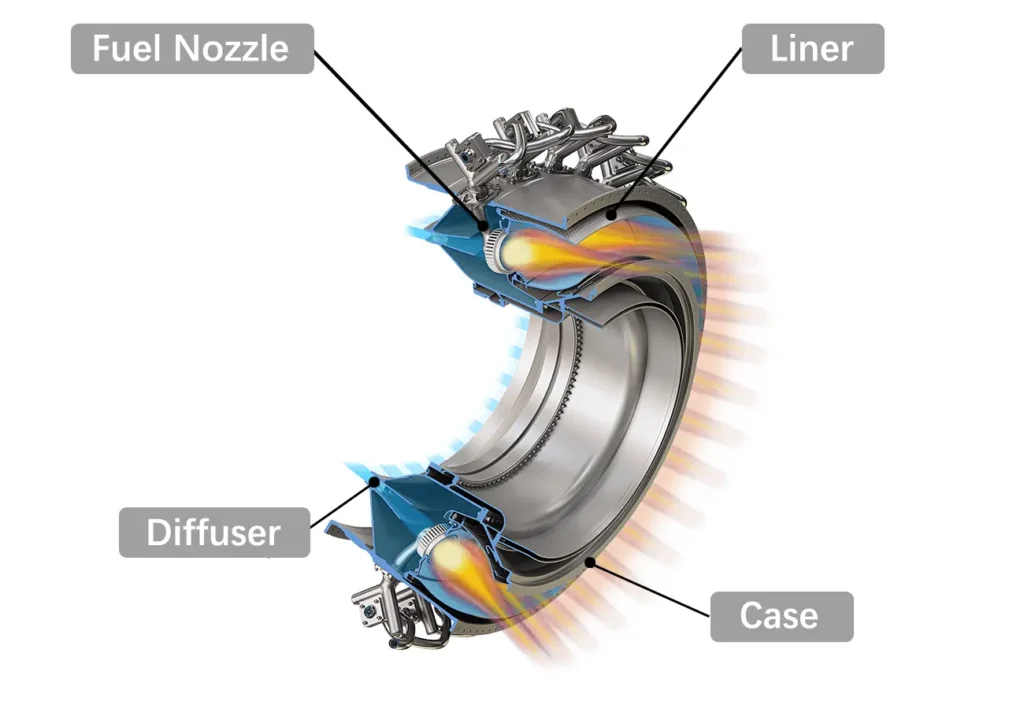

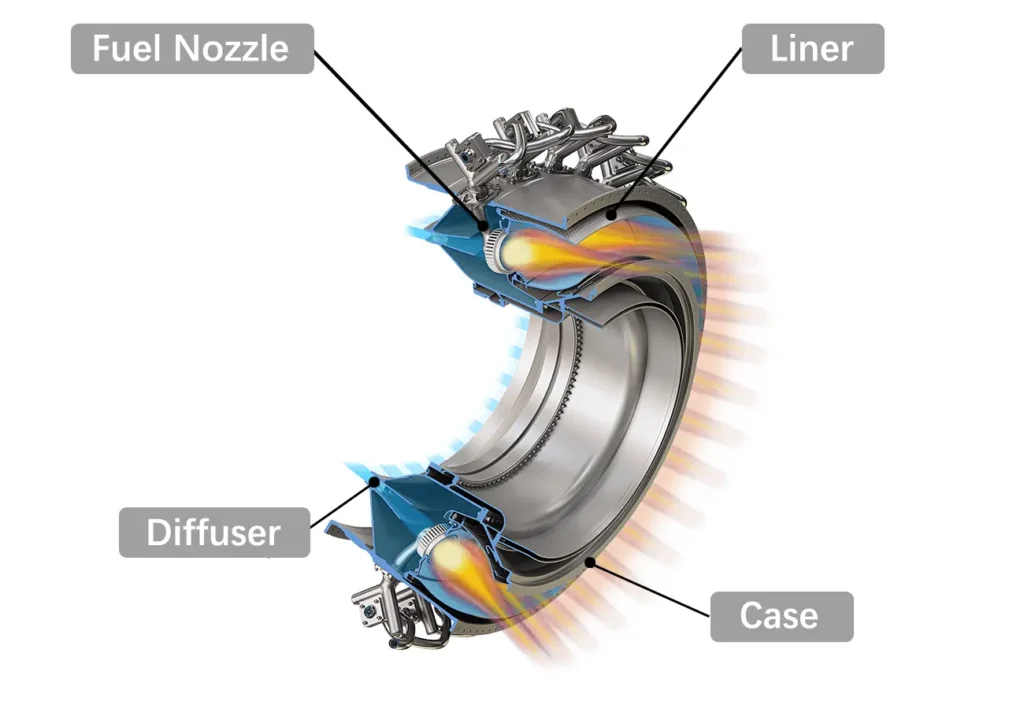

Turbine fuel nozzle tip is a specialized device in jet engine designed to atomize fuel oil for efficient combustion. The effectiveness of atomization directly influences the performance of the combustion chamber, making the fuel nozzle a critical core component. At present, the most advanced global trend is the adoption of three-channel fuel nozzles, which enable staged combustion and support lean premixed strong swirl combustion for improved efficiency and reduced emissions.

Fuel nozzle is the core component of the aircraft engine combustion chamber and directly affects the performance of the combustion chamber. In terms of fuel nozzle components, we have the top manufacturing technology and flow detection capabilities.

Located in the combustor liner, the diffuser reduces the velocity of the airflow coming from the compressor. The current mainstream design integrates OGV (Outlet Guide Vane) blades to minimize pressure loss. Materials commonly used are high-temperature alloys with excellent weldability.

The combustor liner is the component where combustion takes place. The flame is contained within the liner, making it the source of power for the engine. The most advanced global trend focuses on achieving maximum cooling efficiency with minimal cooling airflow, thereby allowing more air to participate in combustion.

The casing forms the outer structure of the combustion chamber, serving as a barrier that separates the combustion zone from the external environment. It requires high structural strength and excellent sealing performance.

Turbine impellers are able to provide high power output at a relatively small size and weight, which makes them particularly popular in various applications, such as aircraft engines and turbochargers.

Impellers are usually made of high temperature resistant alloys, such as nickel-based alloys (Inconel), cobalt-based alloys (Hastelloy), etc., which can work stably for a long time in high temperature environments and have good wear resistance.

The design of impellers usually takes into account the complexity of fluid dynamics to maximize the kinetic energy conversion efficiency of the fluid, reduce energy loss and improve the efficiency of the system.

The manufacture of impellers requires high-precision machining and strict process control to ensure that the geometry, surface quality and dynamic balance of the impeller meet the design requirements, which is crucial to its performance.

Part numbers alone are not sufficient to ensure performance.

To guarantee precision and compatibility, please provide:

Drawings or used samples for reverse engineering.