1.Precisely measure samples using a coordinate measuring machine (CMM) or laser scanner.

2.Record the size, shape and surface characteristics of each part.

Determine the chemical composition of high-temperature alloys using equipment such as spectrometers, X-ray fluorescence spectrometers (XRF) or energy dispersive X-ray spectrometers (EDS).

Analyze the microstructure of materials using metallographic microscopes, scanning electron microscopes (SEM) and other equipment. Evaluate the grain size, phase composition and inclusions of the material

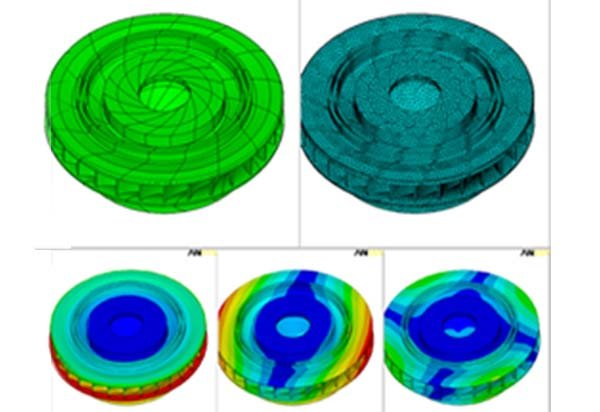

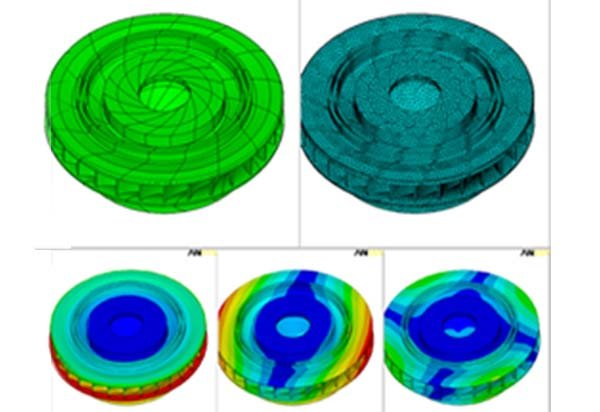

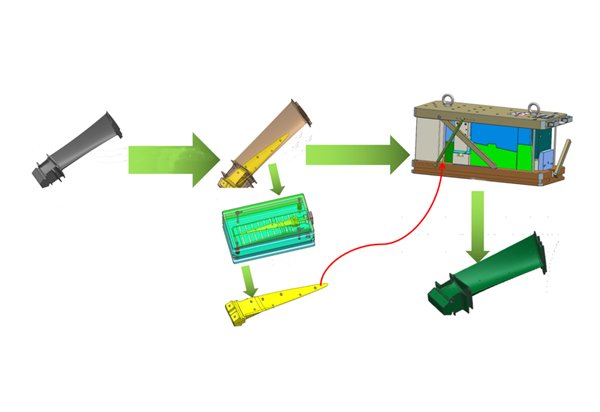

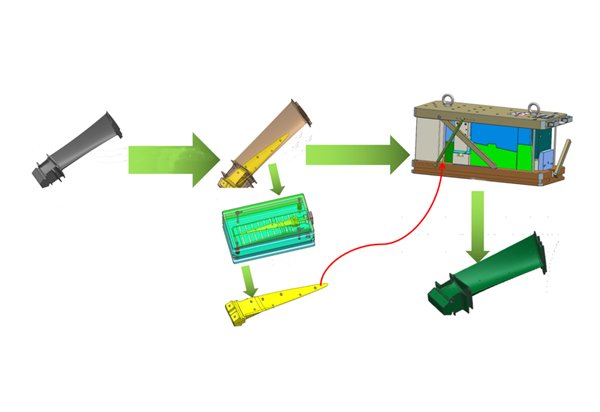

Based on the measured data, use CAD software (such as SolidWorks, CATIA) to reconstruct the 3D model.Make necessary adjustments and optimizations to the model to ensure that it meets the design requirements.

Perform finite element analysis on the model to evaluate its mechanical properties, thermal properties and stress distribution.Adjust the design based on the analysis results.

Determine the manufacturing process, including casting, forging, heat treatment, machining, etc. Select appropriate process parameters and equipment.

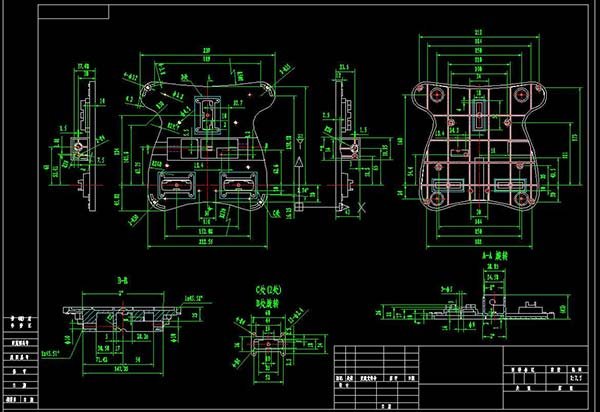

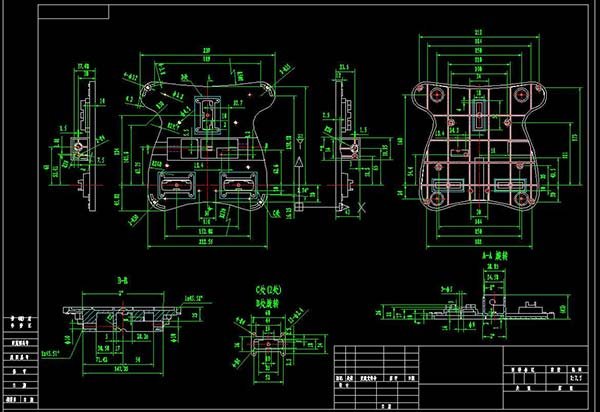

Design and manufacture the required molds or fixtures.Ensure mold accuracy and durability.

The gas turbines operated by an energy company faced aging and performance degradation of blades and impellers. Due to the high price and long delivery cycle of original equipment manufacturers (OEM) parts, the company decided to use reverse engineering technology to develop alternative turbine blades and impellers in-house to reduce maintenance costs and improve equipment availability.

The gas turbines operated by an energy company faced aging and performance degradation of blades and impellers. Due to the high price and long delivery cycle of original equipment manufacturers (OEM) parts, the company decided to use reverse engineering technology to develop alternative turbine blades and impellers in-house to reduce maintenance costs and improve equipment availability.

Gradually shifting to positive R&D:In some technical fields, enterprises are paying more and more attention to the improvement of independent innovation and forward R&D capabilities, and improving their market competitiveness by increasing R&D investment and cultivating professional talents.

Ceramic core molds are used in the manufacturing process of complex metal components, particularly in industries like aerospace and power generation. These molds are used to create ceramic cores, which act as sacrificial patterns during the investment casting process. The ceramic cores are inserted into wax patterns, and after the wax is melted away, the ceramic cores remain in place to form intricate internal passageways within the final cast metal part. This process is critical for producing components with precise internal geometries, such as turbine blades and other high-performance parts.

Part numbers alone are not sufficient to ensure performance.

To guarantee precision and compatibility, please provide:

Drawings or used samples for reverse engineering.