In the field of heavy industry, the more common heat-power conversion type power generation equipment – heavy gas turbine, due to the small footprint, short cycle, high efficiency, less pollution and other characteristics are widely used in power grid peak load, energy mining and transmission, ocean power generation, advanced ship power, aerospace and other fields, called “industrial pearl”. In a certain sense, the overall development level of the national manufacturing industry is closely related to the research and development level of heavy gas turbines.

In 1939, the Swiss BBC company produced the world’s first heavy-duty gas turbine for power generation, which began the rapid development of heavy-duty gas turbines around the world. In recent years, the demand for energy conservation and environmental protection has been growing, and the performance requirements of heavy-duty gas turbines have also been improved, towards the goal of high efficiency and low emissions [1]. There are two main factors affecting the efficiency of gas turbines: one is turbine inlet temperature, and the other is compressor compression ratio. Among them, the more critical thing is how to increase the turbine inlet temperature [2]. Therefore, turbine blades, as the core components of gas turbines, improve turbine inlet temperature mainly rely on three points, namely, high temperature resistant metal materials, advanced cooling technology and thermal barrier coating technology.

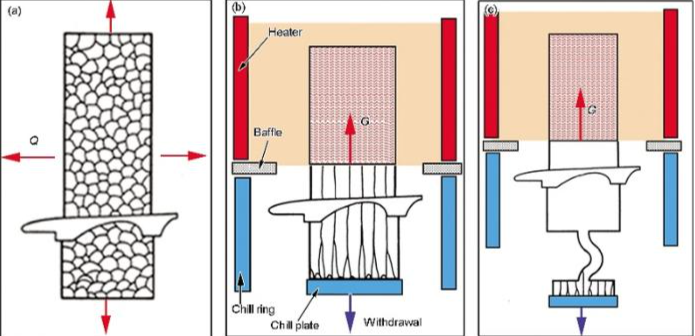

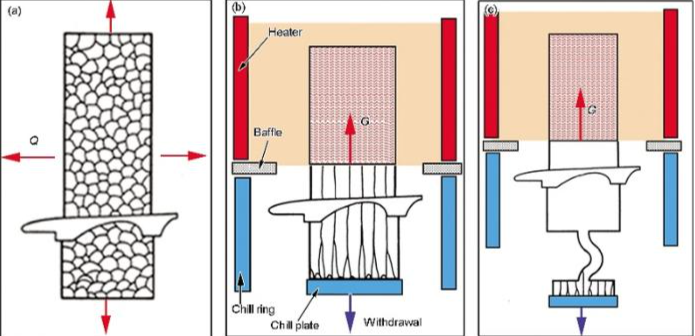

In recent years, superalloy blade directional crystal/single crystal forming technology, thermal barrier coating technology and gas film cooling technology have been vigorously developed [3]. A large number of studies have found that using the designed cooling structure can reduce the surface temperature of the hot end components (turbine blades, combustion chambers, etc.) by about 500 ° C, but it is still not enough to meet the requirements. However, in order to continue to improve turbine cooling technology, the cooling structures designed and manufactured by the researchers are not only very complex, but also difficult to process. In addition, many superalloys used to manufacture heavy duty gas turbine blades have reached their limit temperatures, while ceramic matrix composites with better heat resistance have not been mature for application [4]. In contrast, thermal barrier coating technology has a lower cost and excellent thermal insulation. Studies have shown that the thermal barrier coating of 100 ~ 500μm is deposited on the turbine blade surface by thermal spraying technology, which can avoid the direct contact between high-temperature gas and the turbine blade of the heavy-duty gas turbine, and reduce the surface temperature by about 100 ~ 300℃, so that the heavy-duty gas turbine can be safely put into service [5-6].

Therefore, considering various factors, the only feasible and effective method to achieve high efficiency, low emission and long life of heavy-duty gas turbines is thermal barrier coating technology. This technology is widely used in hot end components of gas turbines and aeroengines. For example, a thermal barrier coating is sprayed on the surface of a turbine blade to separate it from high-temperature gas to reduce the surface temperature of the blade, extend the service life of the blade, and enable it to work at a higher temperature, thereby improving the efficiency of the gas turbine. Since the development of the late 1940s and early 1950s, thermal barrier coating has attracted great attention and been vigorously promoted and developed by many scientific research institutions and coating manufacturers around the world, and the demand for thermal barrier coating technology in modern industry is becoming more and more urgent. Therefore, the study of thermal barrier coating for gas turbines is of great practical and strategic significance.

In recent years, the most widely used coating for heavy-duty gas turbines is still yttrium stabilized zirconia (6-8YSZ) with a mass fraction of 6 wt.% ~ 8 wt.%, but YSZ coating is not only prone to phase transformation and sintering, but also prone to molten salt corrosion at temperatures above 1200℃. That is, CMAS corrosion (CaO-MgO-Al2O3-SiO2 and other silicate substances) and thermal corrosion. In order to make the coating work at temperatures above 1200℃ for a long time, researchers have made many efforts, including finding and developing new thermal barrier coatings, improving the preparation process of thermal barrier coatings, and regulating the structure of the coating. Therefore, on the basis of discussing the status quo of heavy-duty gas turbines and the system structure, materials and preparation methods of thermal barrier coatings, this paper summarizes the research status of gas turbine thermal barrier coatings against CMAS corrosion and other key properties, providing a reference for the research of thermal barrier coatings against CMAS corrosion.

1 Status and development trend of heavy-duty gas turbines

Since the world’s first gas turbine came out in 1920, gas turbines have begun to develop rapidly in the industrial field. In recent years, the scale of the global heavy gas turbine market continues to grow, countries pay more attention to the research and development of heavy gas turbines, and continue to increase capital and manpower investment, and the technical level of heavy gas turbines has been constantly improved. The technical level of heavy-duty gas turbines is determined by the turbine inlet temperature level, which can be divided into E, F and H classes according to the temperature range [7]. Among them, the power of class E is 100 ~ 200 MW, the power of class F is 200 ~ 300 MW, and the power of class H is more than 300 MW.

1.1 Status quo of domestic heavy-duty gas turbines

- In the 1950s, China’s heavy-duty gas turbines needed to be introduced by foreign companies [General Electric (GE), Germany’s Siemens (Siemens), Japan’s Mitsubishi Heavy Industries (MHI)], and then independently designed, developed and manufactured. In this phase, the heavy-duty gas turbine technology of our country has been developed rapidly. In the 1980s, the severe problem of oil and gas shortage occurred in China, and the development of heavy-duty gas turbine technology was forced into a downturn state. Until 2002, with the west-east gas transmission and the development and introduction of natural gas in our country, the problem of oil and gas has been solved, and the heavy-duty gas turbines in our country have finally started a new round of development [8]. At present, China’s heavy gas turbine manufacturing mainly relies on Shanghai Electric, Dongfang Electric, Harbin Electric and other enterprises.

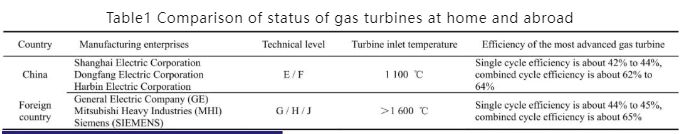

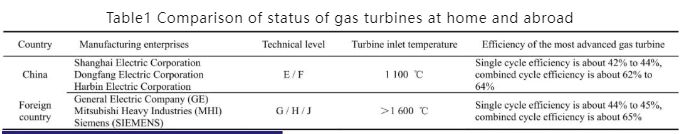

- In 2012, in the “863” major projects in the field of energy, the R0110 heavy-duty gas turbine developed by Shenyang Leing Company and major universities in China successfully completed the 72h load test operation, which marks the successful production of the first heavy-duty gas turbine with independent intellectual property rights, and its base load is 114.5MW. The thermal efficiency is 36%. Since then, China has become the fifth country in the world with independent research and development of heavy-duty gas turbine capability. In 2014, Shanghai Electric bought a stake in Ansaldo, Italy, breaking the foreign monopoly on the gas turbine industry, which also made China initially realize the localization of E/F class heavy gas turbines. In 2019, led by China Re-Combustion, the joint technology of several institutions successfully manufactured the first stage moving blade, the first stage static blade and the combustion chamber of F-class 300 MW gas turbine, which marks that China has been able to initially manufacture the hot end components of heavy gas turbines; In the same year, Shanghai Electric and Ansaldo successfully developed a H class heavy gas turbine GT36, becoming the first H class heavy gas turbine to be developed in our country. In 2020, in the “973” project, the first F-class 50 MW heavy-duty gas turbine (called G50) independently developed by China Dongfang Electric and Xi ‘an Jiaotong University successfully completed the full-load stable test operation [9], which indicates that China has been able to initially independently develop F-class heavy-duty gas turbines. In June 2022, Jiangsu Yonghan participated in the development of 300 MW heavy gas turbine turbine blade after the initial success of the test, marking China’s 300 MW heavy gas turbine research and development success further. However, although the level of heavy-duty gas turbine technology in China is improving rapidly, E/F class gas turbines are still mainly used in the domestic gas turbine market. Among them, the single-cycle efficiency of the most advanced heavy-duty gas turbines in the domestic market is 42% to 44%, and the combined cycle efficiency is 62% to 64%[10].

1.2 Status quo of heavy-duty gas turbines abroad

- Despite the rapid development of global science and technology and economy in recent years, the technical level of heavy duty gas turbines has gradually improved, but a large part of the world’s heavy duty gas turbine market is still divided by the United States GE, Japan MHI, France Alstom and Germany Siemens. With the development of industrial technology, heavy gas turbine technology has become more mature, and the research and development focus has gradually shifted from the field of aviation gas turbines to the field of heavy gas turbines, and E, F, G, H, J class gas turbines have been developed.

- At present, in the heavy gas turbine market, many products of Japan’s Mitsubishi are more popular with the public. Among them, the JAC type gas turbine manufactured by Mitsubishi Heavy Industries is known as the world’s most efficient gas turbine, and its combined cycle power generation efficiency can reach 64% or even higher. The M701J gas turbine, the world’s highest thermal efficiency gas turbine for power generation, has a simple cycle power of 470 MW and a combined cycle power of 680 MW. In addition, the M501J gas turbine still has 55% thermal efficiency under 50% load conditions, and its performance is very excellent.

- The 50 HZ SGT5-9 000HL class heavy gas turbine developed and manufactured by Siemens of Germany is the most powerful heavy gas turbine with the highest output power of a single unit in the world. The heavy-duty gas turbine can produce up to 840 MW of electricity in combined cycle mode, and its combined cycle efficiency is also up to 63%, but it is not the most efficient gas turbine in combined cycle.

- In October 2019, GE launched the 7HA.03 heavy-duty gas turbine, which has a maximum combined cycle output power slightly lower than Siemens’ SGT5-9000HL class heavy-duty gas turbine, reaching 821 MW, but its maximum combined cycle efficiency is estimated to be as high as 63.9%. In 2022, the 7HA.03 gas turbine was put into commercial operation for the first time, with combined cycle power generation efficiency exceeding 64% and load growth rate up to 75 MW/min. The 7HA.03 gas turbine can reduce emissions by 70%. To further reduce carbon emissions from gas-fired power generation, GE’s 7HA.03 gas turbine currently supports the combustion of 50% hydrogen by volume and has a net output of 430 MW in a single cycle. A “one-tow” 7HA.03 heavy-duty gas turbine power plant can provide power generation of up to 640 MW, while a “two-tow” 7HA.03 heavy-duty gas turbine power plant can provide power generation of up to 1 282 MW.

- Today, the inlet temperature of the world’s most advanced heavy-duty gas turbines is as high as 1,600 ° C [11]. Some professionals have predicted that the maximum inlet temperature of gas turbines in the future can reach 1 700℃, and the efficiency of single cycle and combined cycle can reach 44% ~ 45% and 65% respectively [10].

- In summary, although the technical level of heavy-duty gas turbine in China has made great progress compared with the past, there is still a big gap in the level of manufacturing technology and maintenance compared with developed countries, as shown in Table 1. Because of this, domestic manufacturers and researchers should first of all clearly understand the development status of China’s heavy gas turbine, improve the importance of heavy gas turbine research and development, at the same time with the support of national policies, continue to increase the capital investment in heavy gas turbine technology research, focus on the advantages of all parties for the full development of heavy gas turbines. Try to narrow the gap between our country’s heavy-duty gas turbine technology level and that of other developed countries. Therefore, the technical level of heavy-duty gas turbines in China still has a huge space for development, and its future development trend is mainly toward these four aspects, namely, high parameters, high performance, low pollution and large-scale [12].