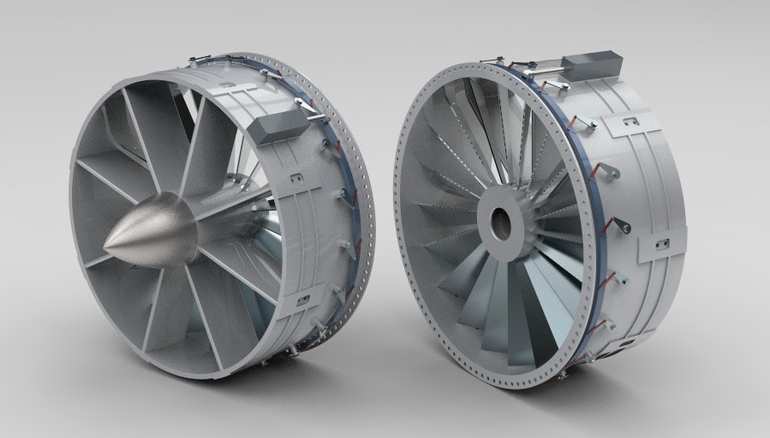

Guide vane, a critical component in various high-performance systems, stands as a testament to the fusion of advanced materials and precision engineering. Among the many materials used in the manufacturing of these vital parts, Inconel 718 has emerged as a leader due to its unparalleled combination of strength, corrosion resistance, and thermal stability. This superalloy, widely recognized for its superior properties, is particularly suited for applications in aerospace, power generation, and other industries where reliability under extreme conditions is non-negotiable.

The Superiority of Inconel 718

Inconel 718 is a nickel-chromium-based superalloy that boasts an impressive array of properties. Its high yield, tensile, and creep-rupture strength, especially at elevated temperatures, make it an ideal material for components that must withstand harsh environments. Additionally, Inconel 718 exhibits excellent resistance to corrosion, oxidation, and fatigue, ensuring that guide vanes remain durable and functional over extended periods. These attributes are crucial in industries where downtime and maintenance costs can significantly impact operational efficiency.

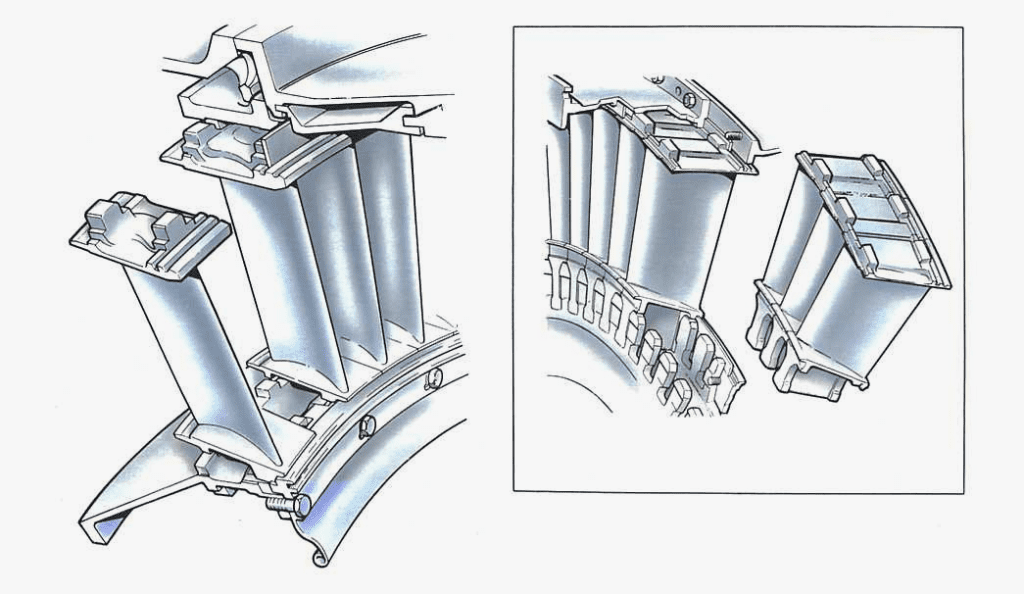

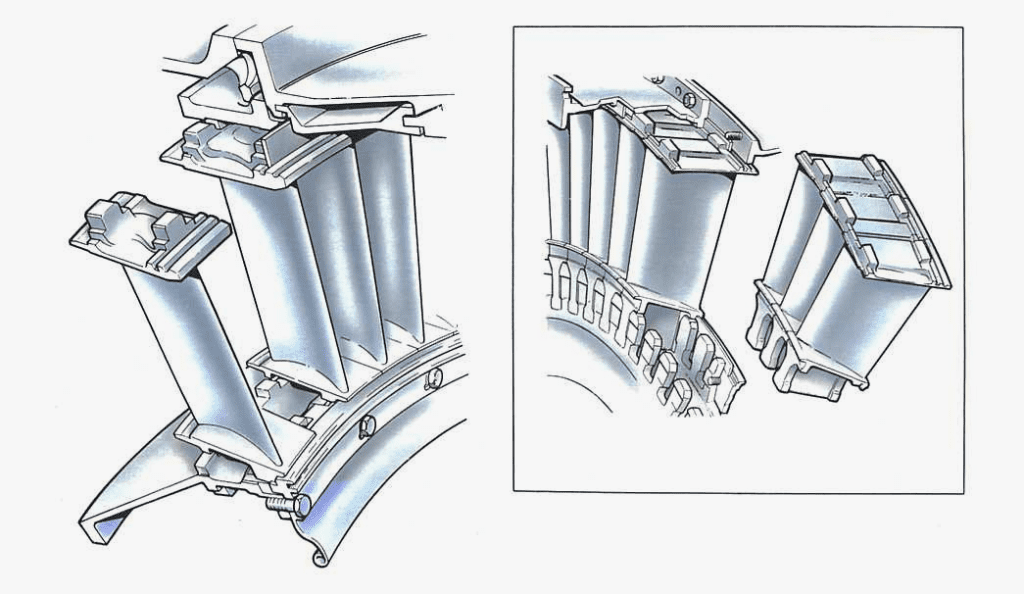

Precision Engineering at Its Best

At our company, we pride ourselves on our ability to craft guide vanes with unparalleled precision and reliability. Our team of experienced engineers and technicians utilizes state-of-the-art manufacturing techniques to ensure that each component meets the highest standards of quality. From initial design to final inspection, every step of the process is meticulously controlled to deliver products that perform consistently under the most demanding conditions.

Reverse Engineering: A Key Differentiator

One of the core competencies that sets us apart is our extensive experience in reverse engineering. This skill allows us to analyze and replicate existing components, often improving upon their original design. Whether you need a direct replacement part or a custom solution tailored to your specific requirements, our reverse engineering capabilities ensure that we can deliver the exact product you need. This approach not only saves time and resources but also guarantees that the final product is optimized for performance and longevity.

Customization and Innovation

We understand that every project is unique, and our commitment to customization and innovation reflects this understanding. Our design team works closely with clients to develop guide vanes that meet or exceed their specifications. By leveraging our deep knowledge of Inconel 718 and advanced manufacturing technologies, we can create components that enhance the overall performance of your systems. Whether you are looking to improve efficiency, reduce wear and tear, or extend the service life of your equipment, we have the expertise to help you achieve your goals.

Quality Assurance and Testing

Quality is at the heart of everything we do. Each guide vane undergoes rigorous testing to ensure it meets or exceeds industry standards. Our comprehensive quality assurance program includes material verification, dimensional inspection, and performance testing. We use the latest inspection equipment and techniques to detect any potential issues before they become problems in the field. This commitment to quality ensures that our clients can rely on our products to perform consistently and reliably.

Case Studies and Success Stories

- To illustrate the effectiveness of our guide vanes, let us share a few success stories. In one notable project, we worked with a leading aerospace manufacturer to develop guide vanes for a new engine design. The challenge was to create components that could withstand the extreme temperatures and pressures encountered during flight. Through our expertise in Inconel 718 and precision engineering, we delivered guide vanes that not only met but exceeded the client’s expectations. The result was a more efficient and reliable engine, which helped the manufacturer gain a competitive edge in the market.

- In another instance, we collaborated with a power generation company to address issues with premature wear in their turbine guide vanes. By reverse engineering the existing components and optimizing the design, we were able to significantly extend the service life of the vanes. This not only reduced maintenance costs but also improved the overall performance of the turbines.

Partnering for Success

At our company, we believe that the key to success lies in building strong partnerships with our clients. We are dedicated to providing not just products but comprehensive solutions that address your unique challenges and opportunities. Our team is always available to discuss your project requirements and offer expert advice to help you make informed decisions.

Contact Us Today

If you are looking for a reliable and innovative partner in the development and production of high-performance guide vanes made from Inconel 718, look no further. Contact us today to discuss how we can support your project and bring your vision to life. Whether you need a single component or a full production run, our team is ready to assist you every step of the way. Let us be your trusted ally in achieving excellence in your industry.