During routine maintenance inspections, our customer found that the first-stage single crystal turbine blades of its high-pressure turbine (HPT) had surface corrosion, microcracks, and local material loss. Given the excellent performance of single crystal turbine blades in high temperature environments, it is particularly important to repair them efficiently and reliably.

1. Damage assessment

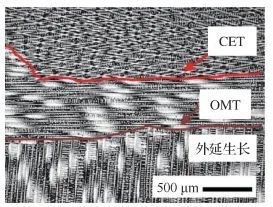

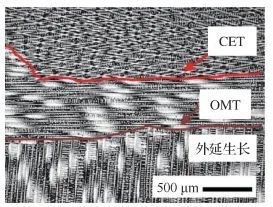

- Metallographic analysis: by sampling for microstructural observation, analyze the microstructural changes in the damaged area, and evaluate the degree of material performance degradation.

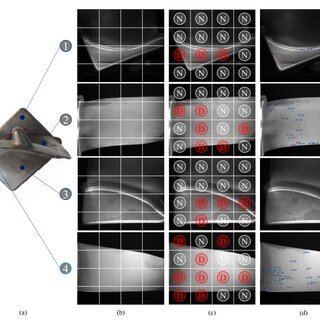

- lNon-destructive testing (NDT)

- lUltrasonic testing (UT): used to detect internal cracks and material defects.

- lEddy current testing (ET): used to detect surface and near-surface cracks.

- lX-ray computed tomography (XCT): used to obtain three-dimensional images of the internal structure of the blade and evaluate the depth and extension of the crack.

Based on the damage assessment results, the following repair plan was formulated:

- Surface pretreatment

- lPlasma sandblasting: remove the oxide layer and contaminants on the blade surface.

- l Laser shock strengthening (LSP): Close micro cracks and improve fatigue life.

3. Material filling and repair:

- Electron beam welding (EBW): For the parts with local material loss, use nickel-based high-temperature alloy powder with high matching degree with the substrate for precise repair welding.

- Hot isostatic pressing (HIP): Eliminate welding residual stress and improve the organizational structure of the welding area.

4. Heat treatment:

- l Aging treatment: Optimize the high temperature performance of the material.

- l Solution treatment: Restore the microstructure and mechanical properties of the blade.

5. Precision machining and surface treatment:

- Five-axis linkage CNC machine tool (CNC): Precision machining of the repaired blade to ensure that the dimensional accuracy meets the design requirements.

- Chemical nickel plating or physical vapor deposition (PVD): Provide an additional protective layer for the blade surface to enhance corrosion resistance and wear resistance.

6. Final inspection and verification:

- Non-destructive testing: Perform ultrasonic testing, eddy current testing and X-ray computed tomography again to confirm that there are no defects in the repaired area.

- Mechanical performance test: static tensile test, fatigue test and high temperature creep test were carried out to verify the mechanical properties of the repaired blades.

7. Repair results and benefits

- Performance recovery: The repaired single crystal turbine blades performed well in various performance tests and reached the original factory standards.

- Economic efficiency: Compared with replacing new blades, the repair scheme greatly reduced the maintenance cost and shortened the maintenance cycle.

- Safety: The repair process was strictly carried out in accordance with aviation industry standards to ensure the safety and reliability of the repaired blades.

Conclusion

This case shows the whole process of single crystal turbine blades from damage assessment to repair completion, highlighting advanced repair technology and strict quality control measures. Through a scientific and reasonable repair scheme, not only the service life of the blades was effectively extended, but also the economic benefits and operational efficiency of the airlines were significantly improved.

Thank you for your interest in our company! As a professional gas turbine parts manufacturing company, we will continue to be committed to technological innovation and service improvement, to provide more high-quality solutions for customers around the world.If you have any questions, suggestions or cooperation intentions, we are more than happy to help you. Please contact us in the following ways:

- WhatsAPP:+86 135 4409 5201

- E-mail:peter@turbineblade.net