Stellite is a high temperature alloy, mainly composed of cobalt (Co) base, with excellent wear resistance, corrosion resistance and high temperature resistance. Stellite alloy is widely used in various industrial fields, especially those that need to work in harsh environments, such as aerospace, petrochemical, power generation and nuclear industries.

The main matrix element of Stellite, providing high temperature strength and oxidation resistance.

Enhances the corrosion resistance of the alloy.

Improves the hardness and wear resistance of the alloy.

Enhances the hardness and wear resistance of the alloy by forming carbides.

Stellite alloy has extremely high hardness and can maintain excellent wear resistance under high friction and high stress conditions.

Due to the presence of chromium, Stellite alloy can remain stable in acidic, alkaline and oxidizing environments.

Stellite can maintain its mechanical properties and chemical stability at high temperatures, suitable for working under extreme temperature conditions.

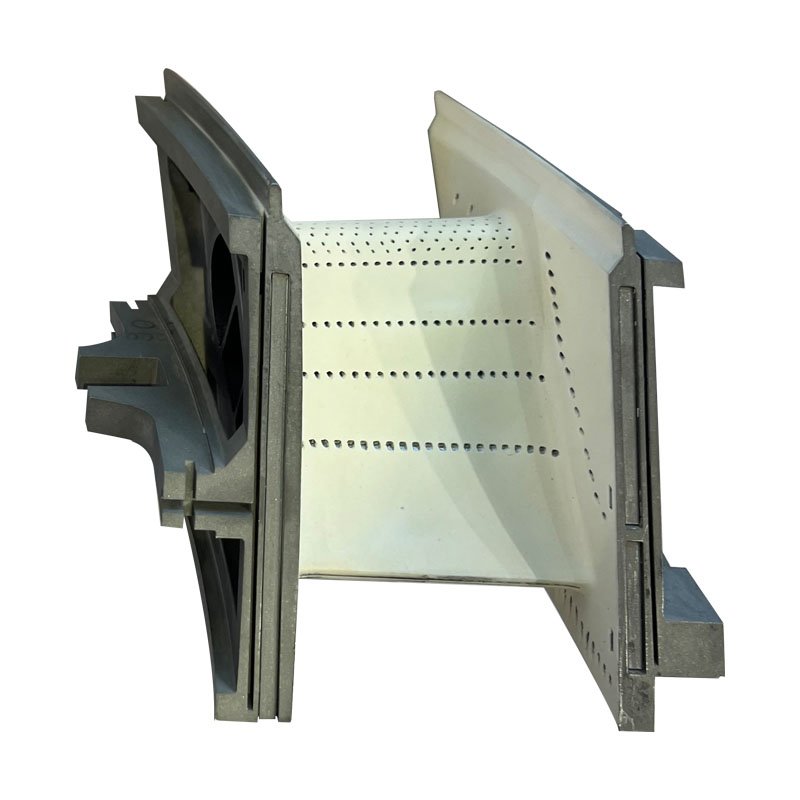

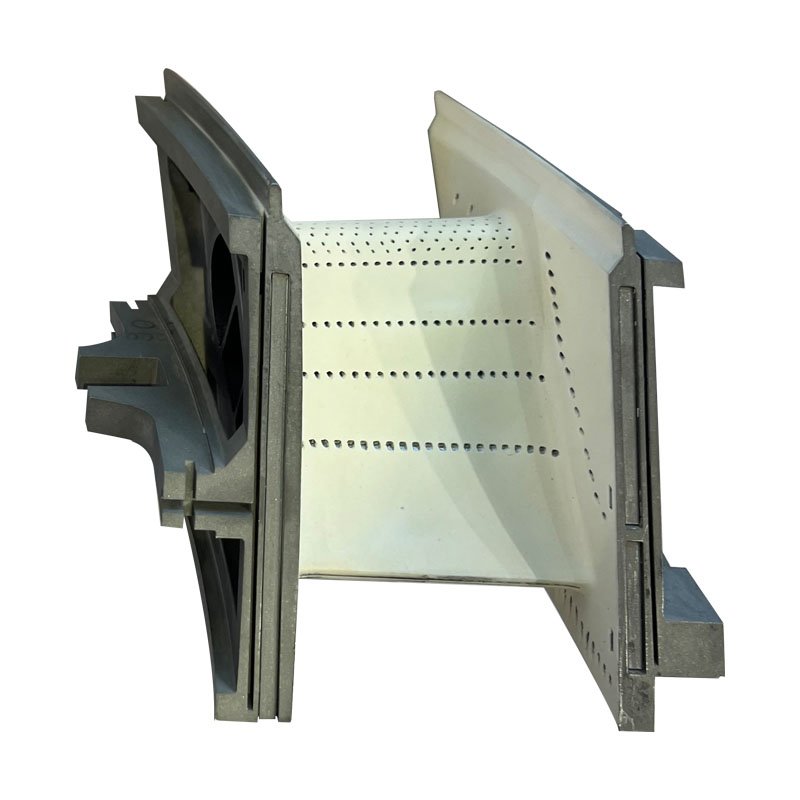

For machined Stellite cast turbine products, suitable processing technology and tools are required to cope with their high hardness and wear resistance. Advanced CNC machining technology may be used to ensure the accuracy and efficiency of machining.

In equiaxed crystal casting, this helps to make Stellite cast turbine products have more uniform mechanical properties and good comprehensive performance. The formation of equiaxed crystals is promoted by precisely controlling various parameters in the casting process, such as temperature, cooling rate, etc. This can improve the reliability and stability of the product in use, making it better adapted to various working conditions and environments.

Aerospace industry: In the aerospace field, Stellite products are often used to manufacture high-temperature and high-pressure parts such as turbine blades, turbine disks, and turbine shafts because they can withstand extreme working conditions and harsh environments.

Energy industry: In the energy industry, Stellite products are often used to manufacture key components such as turbines, gas turbines, and turbine generators, which require wear resistance, corrosion resistance, and high temperature resistance.

Oil and gas industry: Stellite products play an important role in the extraction, processing, and transportation of oil and gas. For example, they are used to manufacture key wear-resistant and corrosion-resistant components such as valves, pumps, and drill bits.

Medical devices: Stellite alloys are also widely used in the field of medical devices, such as artificial heart valves, orthopedic implants, etc., because of their biocompatibility and corrosion resistance.

Automobile and shipbuilding: In automobile and shipbuilding, Stellite products are often used to manufacture high-performance engine parts, turbochargers, etc. to improve the performance and reliability of vehicles or ships.

Turbine blades made of equiaxed casting are widely used in aircraft engines and gas turbines. These blades have good high temperature strength and corrosion resistance, and are suitable for high temperature and high pressure parts of turbines.

Turbine disks are important components that support turbine blades and transmit power. The equiaxed casting process can produce turbine disks with good mechanical properties and durability, which are suitable for various turbine equipment.

Combustion chamber liners need to work in high temperature and high pressure environments. The equiaxed casting process can produce liners with high temperature oxidation resistance and corrosion resistance.

Widely used in aircraft engines and gas turbines. This design helps to improve the manufacturing accuracy of blades, reduce stress concentration, and facilitate replacement and maintenance.

Guide vanes are used to adjust the airflow direction and improve the working efficiency of turbines. Equiaxed casting can ensure that these blades have uniform grain structure and good mechanical properties.

Engine turbine accessories also include several key components, each of which plays a vital role in the high temperature, high pressure and high speed environment of the engine.

Part numbers alone are not sufficient to ensure performance.

To guarantee precision and compatibility, please provide:

Drawings or used samples for reverse engineering.