Our cooperative customer is a manufacturer of civil helicopters and commercial aircraft. The demand for engine parts is very high, and it requires durability. According to the requirements of our own country, we also propose the need to achieve energy conservation and emission reduction.In order to meet the needs of our customers, after discussion by the technical department, we decided to use the material inconel 939 for manufacturing, because the inconel 939 turbine blade can maintain good mechanical properties and strong corrosion resistance at high temperatures, ensuring the efficiency of use.

1.Design stage

- Customer demand analysis: Our technical team conducted detailed discussions and docking with customers in various aspects, and understood the specific needs of customers’ usage scenarios, including key information such as estimated operating temperature and operating pressure, and life expectancy.

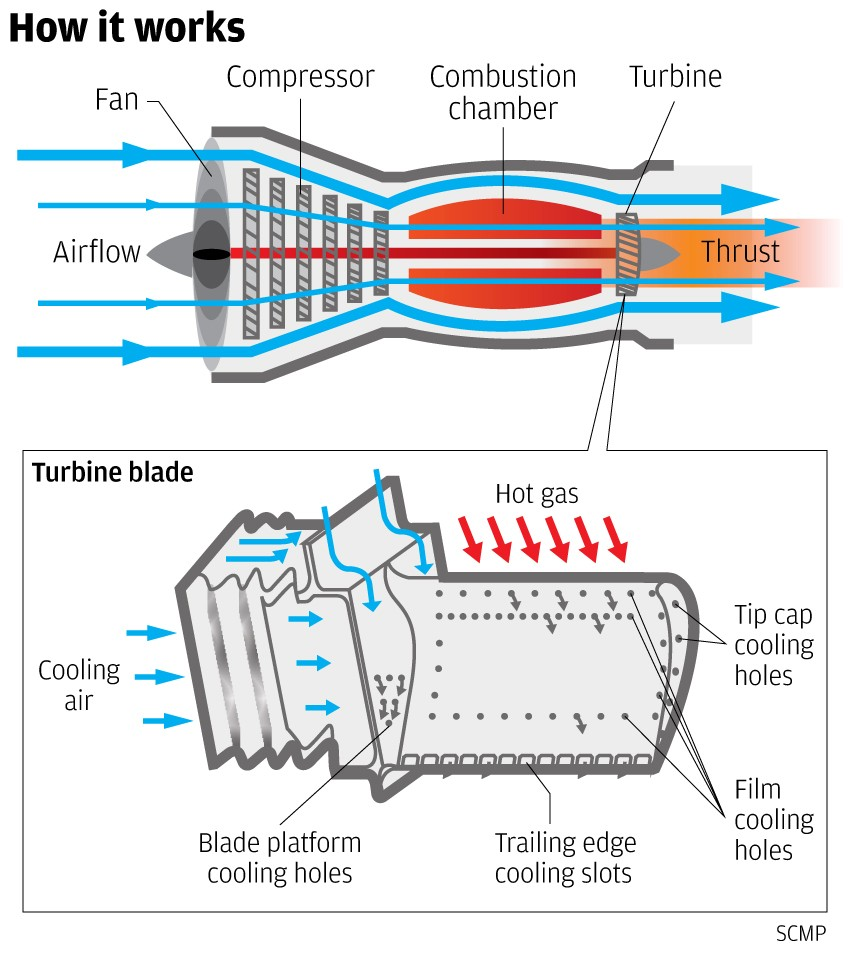

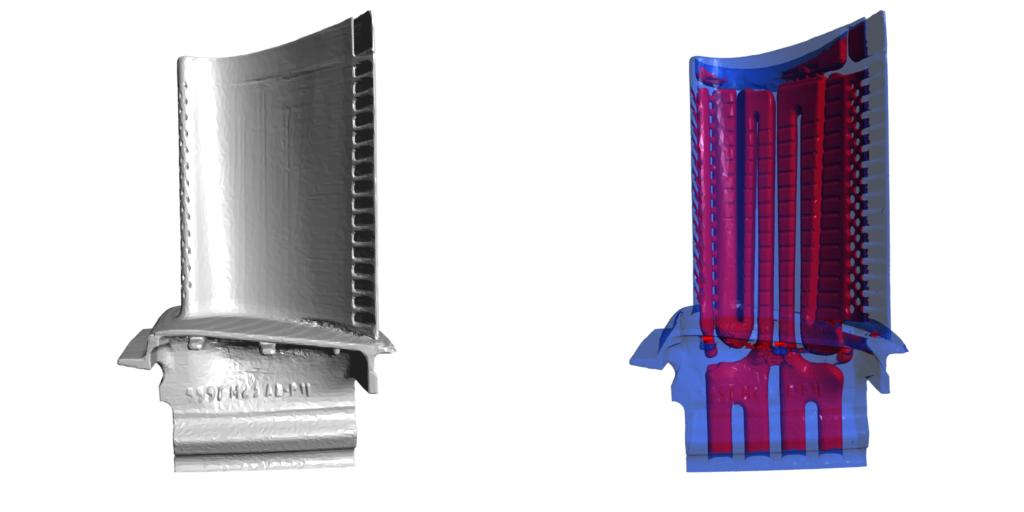

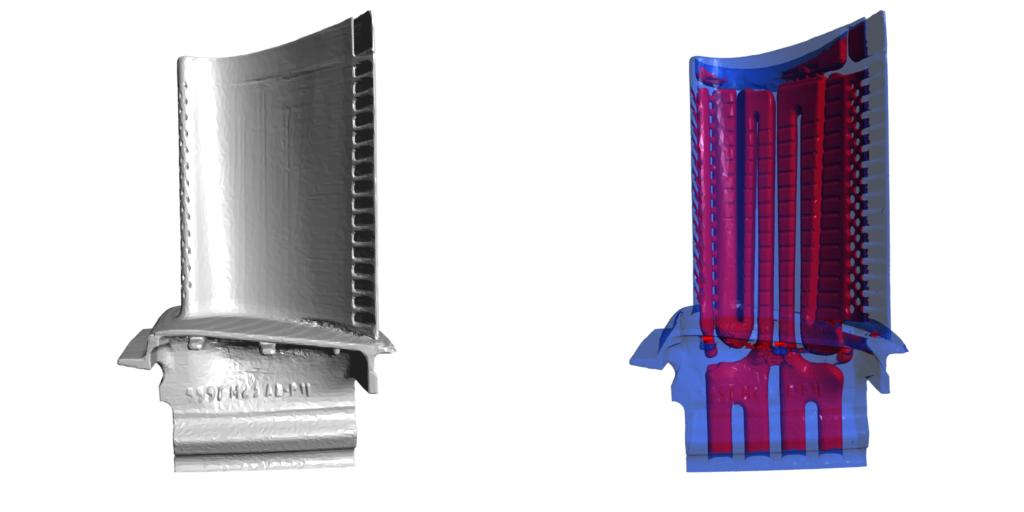

- Preliminary design:Based on customer demand information, our team used advanced computer-aided design (CAD) software to create a three-dimensional model of the turbine blade, and used the fluid mechanics simulation tool (CFD) to check the consistency of the blade shape and optimize it to ensure the best aerodynamic performance.

- Material selection: After determining the basic design and confirming with the customer, Inconel 939 was selected as our main material to ensure the excellent heat resistance and strength characteristics of this product.

2.Production process

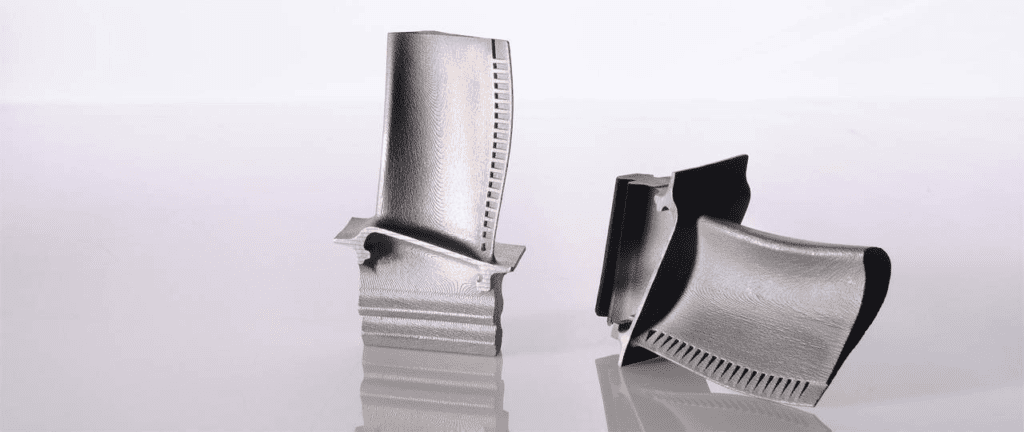

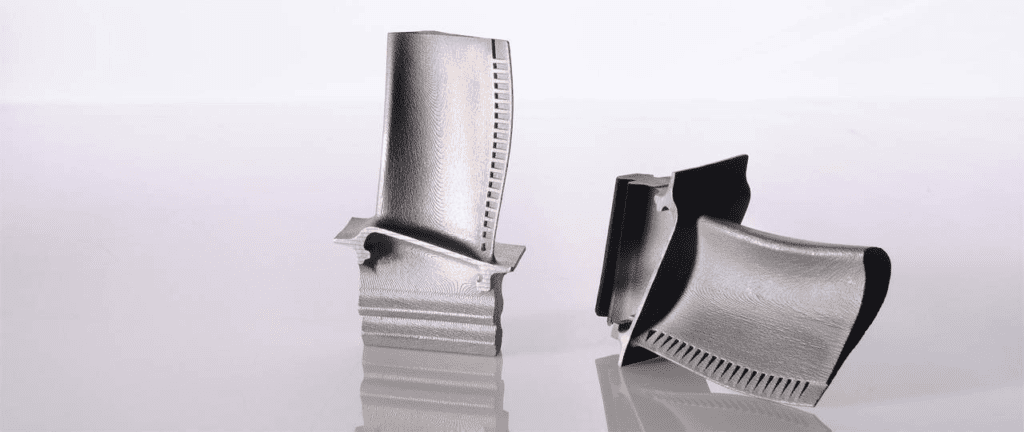

- Suitable for precision casting: Due to the particularity of the material inconel939 and the difficult processing characteristics, we chose casting technology to produce this complex turbine blade after discussion. In the manufacturing process, we need to manufacture high-precision wax film and ceramic shell, as well as subsequent liquid metal pouring and other steps.

- Directional solidification: In order to meet customer requirements and enhance the consistency of the grain direction of the material, we use a directional solidification process, which not only effectively improves the uniformity of the internal organization of the turbine blade, improves the overall mechanical properties, and can also ensure that customers are environmentally friendly and energy-saving. The idea of improving quality and efficiency.

- Heat treatment: After completing the casting process, all our finished products have undergone a comprehensive heat treatment process, including solution treatment and aging hardening, which further enhances the hardness and toughness of this product.

3.Inspection and testing

- Non-destructive testing: We choose to use X-rays to check the inside and outside of each finished product for defects or cracks that are not visible to the naked eye.

- Mechanical properties testing of finished products: Due to the large number of finished products, we use the sampling inspection method to take a part of the samples for tensile testing, fatigue testing and other performance tests to ensure that the products can meet customer needs and quality standards in all aspects.

- Environmental simulation experiment: We take out the finished products we produce as samples, put them in a simulated actual working environment, and simulate long-term use and operation to verify the long-term stability and reliability of the finished products.

4.Results show

After several months of production and customer communication efforts, our technical team and production department successfully delivered a batch of high-quality inconel 939 turbine blades and successfully delivered them to customers.It was mentioned in the customer’s feedback that this batch of products not only reached the technical indicators originally set, but also met their concept of environmental protection. They exceeded expectations in use and achieved good results.The customer’s feedback also mentioned that they will continue to cooperate with us in the next few years, hoping that we will continue to make good-quality products, provide services for their new engines, and bring them significant cost savings and environmental benefits.

Thank you for your interest in our company! As a professional gas turbine parts manufacturing company, we will continue to be committed to technological innovation and service improvement, to provide more high-quality solutions for customers around the world.If you have any questions, suggestions or cooperation intentions, we are more than happy to help you. Please contact us in the following ways:

- WhatsAPP:+86 135 4409 5201

- E-mail:peter@turbineblade.net