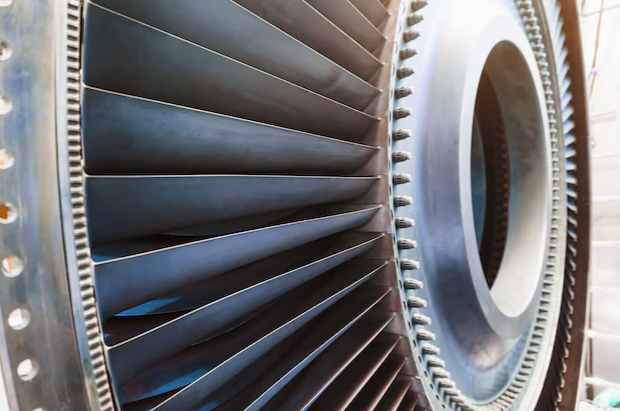

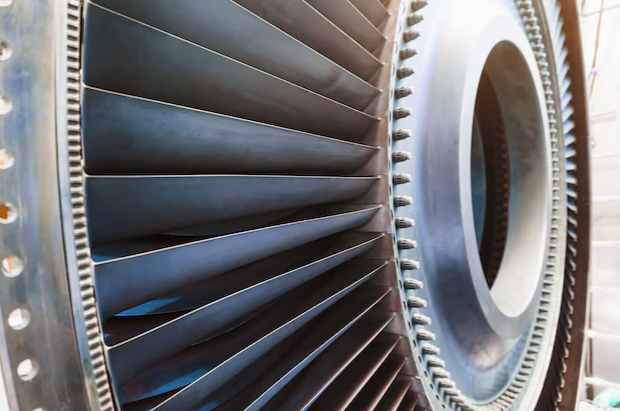

In the highly sophisticated and fiercely competitive domain of gas turbines, the turbine disc emerges as a linchpin component, exerting a profound influence on the holistic performance and dependability of these formidable machines. Turbine discs, preponderantly crafted from high-performance materials like Inconel 718, reside at the core of the turbine section, where they must withstand an array of extreme operating conditions.

Inconel 718, a nickel-chromium alloy of preeminent stature, is celebrated for its extraordinary mechanical attributes. It flaunts high tensile strength, remarkable creep resistance, and an enviable fatigue life, thereby rendering it an optimal selection for turbine discs. These discs are incessantly assailed by intense centrifugal forces, searing temperatures, and intricate thermal gradients during the operation of gas turbines. The capacity of Inconel 718 to uphold its structural integrity under such unforgiving circumstances is not only essential but also non-negotiable for the secure and efficient operation of the gas turbine.

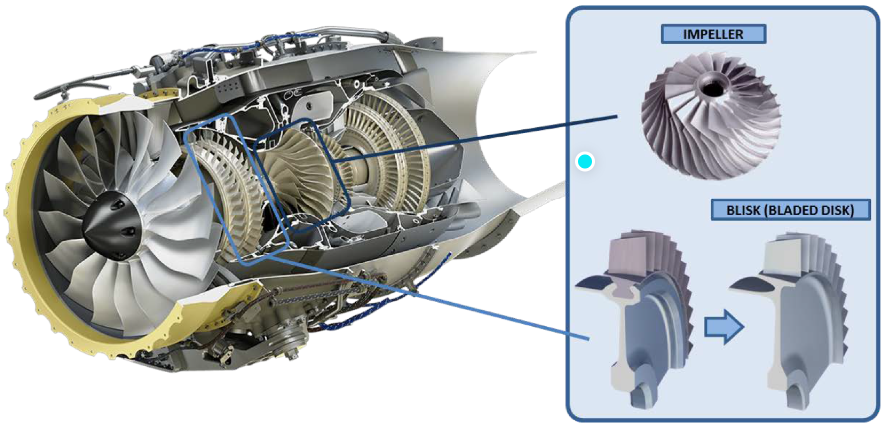

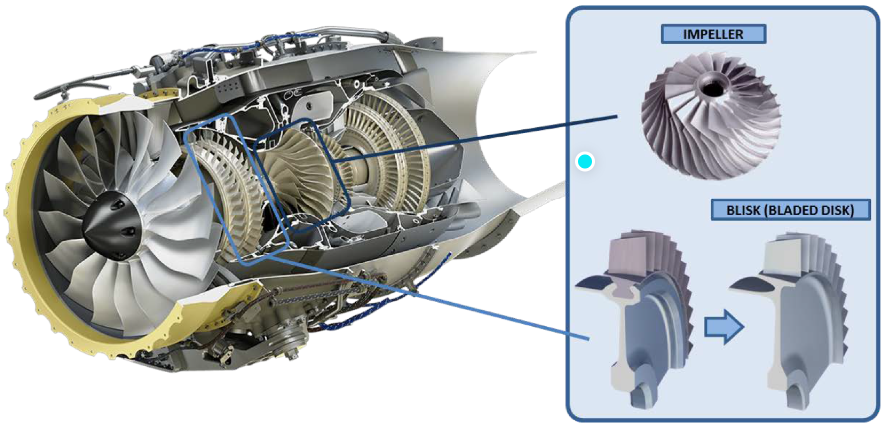

The contemporary gas turbine industry is presently traversing a phase of ceaseless innovation and expansion. In the face of the escalating global exigency for clean and efficient energy, gas turbines have commandeered a central role in power generation. They are ubiquitously deployed in conventional power plants and have also found a prominent place in nascent combined cycle power generation architectures. Moreover, their indispensability extends to the aerospace realm, where they serve as the powerhouses of aircraft engines, furnishing reliable propulsion. In this milieu, the caliber and performance of turbine discs assume a position of paramount significance.

Manufacturers of gas turbine components are perpetually engaged in a relentless pursuit of refining the manufacturing processes of turbine discs. State-of-the-art machining methodologies, such as ultra-precision milling and grinding, are harnessed to attain the requisite dimensional precision and surface finish. Concurrently, heat treatment regimens are painstakingly calibrated to augment the material properties of Inconel 718. For instance, the parameters of solution annealing and aging treatments are scrupulously modulated to procure the coveted blend of strength and ductility. Quality control and inspection protocols for turbine discs have likewise scaled new zeniths of refinement. Non-destructive testing modalities, encompassing ultrasonic testing, magnetic particle inspection, and X-ray tomography, are enlisted to ferret out any internal or surface flaws. These techniques function as sentinels, ensuring that only discs of the zenith quality are integrated into gas turbines, thereby attenuating the jeopardy of in-service failures to a bare minimum.

Research and development initiatives within the industry are zeroed in on further augmenting the performance of turbine discs. This encompasses probing novel alloy formulations and microstructural tweaks to supercharge high-temperature competencies and resilience against environmental deterioration. For example, ongoing investigations are plumbing the depths of the consequences of incorporating trace elements into Inconel 718 and the ramifications of diverse grain boundary engineering stratagems.

Another significant aspect is the optimization of the disc’s aerodynamic design. Engineers are constantly exploring ways to improve the flow of gases over and around the turbine disc, reducing turbulence and pressure losses. Computational fluid dynamics (CFD) simulations are widely used to model and analyze different design configurations, allowing for more informed decisions in the design process. This not only enhances the overall efficiency of the gas turbine but also contributes to the longevity of the turbine disc by minimizing the stresses induced by uneven gas flow.

Furthermore, the supply chain for turbine discs and their associated materials is a complex and global network. The availability and quality of raw materials, such as nickel and chromium, which are essential for Inconel 718, can have a significant impact on production schedules and costs. Manufacturers are increasingly focusing on building reliable and sustainable supply chains, collaborating with suppliers to ensure a steady and high-quality source of materials.

In the area of maintenance and repair, advanced techniques are being developed to address issues such as cracks and surface damage in turbine discs. Laser cladding and other additive manufacturing-based repair methods are showing great promise in restoring the integrity of damaged discs, potentially extending their service life and reducing the need for costly replacements.

In summation, turbine discs fabricated from Inconel 718 are the bedrock of the gas turbine industry. Their unwavering performance is the cornerstone underpinning the efficient and secure operation of gas turbines across a gamut of applications. If you are intrigued by delving deeper into the realm of top-tier turbine discs or contemplating prospective partnerships in the gas turbine component sphere, do not hesitate to reach out to our company. We possess a cadre of virtuosos armed with profound erudition and avant-garde technologies, wholeheartedly dedicated to proffering peerless turbine disc solutions. Contact us at Peter@turbineblade.net and let’s embark on a dialogue about how we can satiate your gas turbine component requisites and catalyze the fruition of your projects.