At present, there is a clear understanding of the influence and mechanism of hot corrosion on the fatigue performance of turbine disk alloys. However, similar to high-temperature alloys for turbine blades, existing research results are mainly based on pre hot corrosion of turbine disk alloys and fatigue tests, which cannot reflect the interaction between hot corrosion and mechanical loads in real time. Therefore, further research is needed to investigate the fatigue failure mechanism and law of turbine disk alloys under the coupling effect of hot corrosion and fatigue loads. In addition, for turbine disks, in order to improve the level of damage tolerance design and meet the durability, reliability, and safety design requirements of high thrust to weight ratio aircraft engines in marine service environments, it is necessary to conduct in-depth research on the fatigue crack propagation testing method and micro mechanism of high-temperature alloys used for turbine disks under marine environment working condition coupling, providing data and technical support for the fatigue crack propagation life prediction method and damage tolerance design of aircraft engine turbine disk materials.

Hot corrosion fatigue life prediction method

The fatigue process in high-temperature corrosive environments is simultaneously affected by load, temperature, and corrosive medium, and its effects are more complex. The damage process is divided into the initiation and growth of hot corrosion pits, the transformation of hot corrosion pits into fatigue cracks, the initiation of fatigue cracks, the propagation of small cracks, the propagation of long cracks, and fracture [73,74]. During these damage processes, the initiation and growth of hot corrosion pits, as well as crack initiation and small crack propagation, account for the vast majority (70% to 80%) of the fatigue life. In the research of hot corrosion fatigue models, high-temperature hot corrosion fatigue life prediction models need to consider many factors such as temperature, load level, and medium concentration. The commonly used fatigue life prediction models currently include phenomenological models, damage mechanics models, and fracture mechanics models [75,76]. The phenomenological model is mainly based on the characterization of hot corrosion damage characteristics and the modification of stress or strain life equations to a certain extent; The damage mechanics model mainly characterizes hot corrosion damage, establishes damage variables that couple hot corrosion damage and mechanical load damage, and establishes the relationship between the evolution of damage variables and fatigue life; The fracture mechanics model considers hot corrosion damage as the initial crack and uses fracture mechanics theory to predict and evaluate the remaining life.

However, phenomenological models, damage mechanics models, and fracture mechanics models for predicting hot corrosion fatigue life each have their own advantages and disadvantages. The phenomenological model is simple and can accurately predict the hot corrosion fatigue life, but it cannot reflect the hot corrosion fatigue mechanism and its prediction accuracy depends on a large amount of experimental data; The damage mechanics model can also obtain relatively accurate prediction results, but it is often limited to some simple structures; The fracture mechanics model can be used for complex structures, but it does not consider the fatigue life during the crack initiation stage, so the prediction results often tend to be conservative. Recently, Zhao Gaole et al. [75] conducted a systematic summary and induction of the hot corrosion fatigue life model in their review. Therefore, the following text focuses on summarizing the methods for predicting the hot corrosion fatigue life of turbine blades and turbine disk alloys in the past 10 years. Given that the current literature on the prediction and analysis of hot corrosion fatigue life of high-temperature alloys for turbine disks and turbine blades does not take into account the microstructural characteristics of high-temperature alloys, and the constitutive equations used to describe the deformation of high-temperature alloys are all macroscopic phenomenological constitutive equations. Therefore, the summary and introduction of hot corrosion fatigue life prediction methods in this section will no longer distinguish between turbine disk alloys and turbine blade alloys.

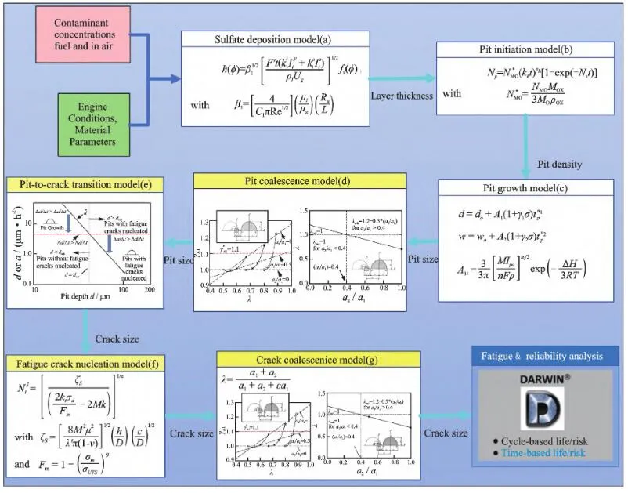

In recent years, with funding from NASA, Elder Research Institute (ERI) and Southwest Research Institute (SwRI) Chan et al. [77] have developed a physics based modeling tool HOTPITS for predicting the hot corrosion [78] and low-temperature hot corrosion life of nickel based superalloys, and combined it with the probability damage tolerance analysis software DARWIN for predicting fatigue failure caused by corrosion pits in engine discs. The schematic diagram is shown in Figure 10, which mainly includes: (1) a sulfate deposition model for predicting the formation of sulfate layers on hot end components based on input of pollutant concentrations in fuel and air, as well as relevant engine conditions; (2) A hot corrosion pit initiation model used to predict the density of hot corrosion pits; (3) A growth model for predicting the size of hot corrosion pits over time. At the same time, in response to the situation where hot corrosion often accompanies the formation of multiple hot corrosion pits, a model considering the merging of hot corrosion pits has been further developed to deal with the growth and merging of multiple corrosion pits.

In order to consider the influence of corrosion pits in hot corrosion fatigue life prediction, a transformation model from corrosion pits to cracks, a fatigue crack nucleation model, a growth model, and a crack merging model were established. By combining HOTPITS with DARWIN [79] software, Chan et al. studied the powder high-temperature alloy ME3 and found that there is competition between hot corrosion pit growth and fatigue crack growth. The low-temperature hot corrosion fatigue life is jointly controlled by hot corrosion pit growth, cycle related crack propagation, and time-dependent crack propagation. A probability prediction method for predicting the corrosion fatigue crack propagation life of powder high-temperature alloy turbine discs is proposed, which can be used to evaluate the risk of failure caused by hot corrosion in turbine discs and avoid corrosion fatigue failure of engine discs and other metal structural components due to long-term exposure to high-temperature extreme environments.

Li et al. [80] proposed a corrosion fatigue life prediction method that considers corrosion pits in FGH96 alloy as micro notches, taking into account the effects of hot corrosion and non-uniform stress fields. Firstly, LCF tests were conducted on uncoated and coated samples made of powder high-temperature alloy FGH96, and Faraday’s law was used to estimate the formation time of hot corrosion pits.