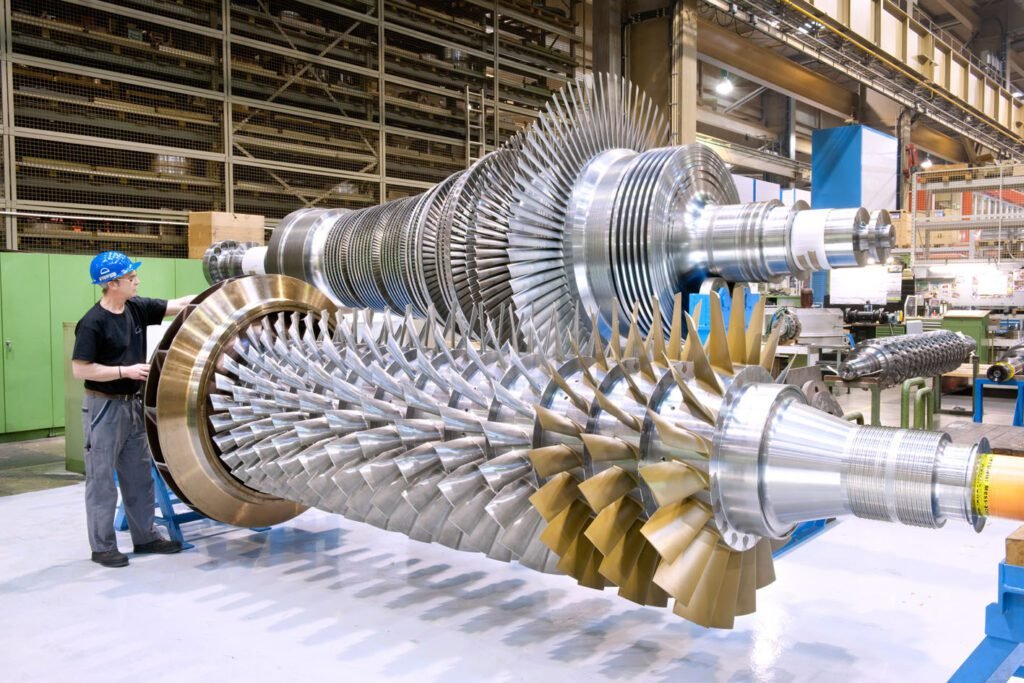

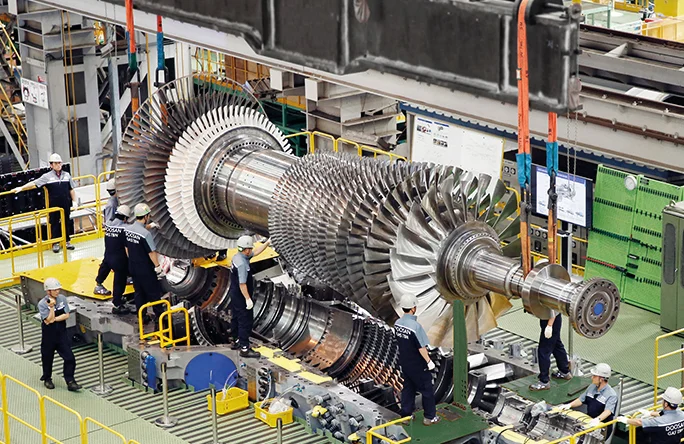

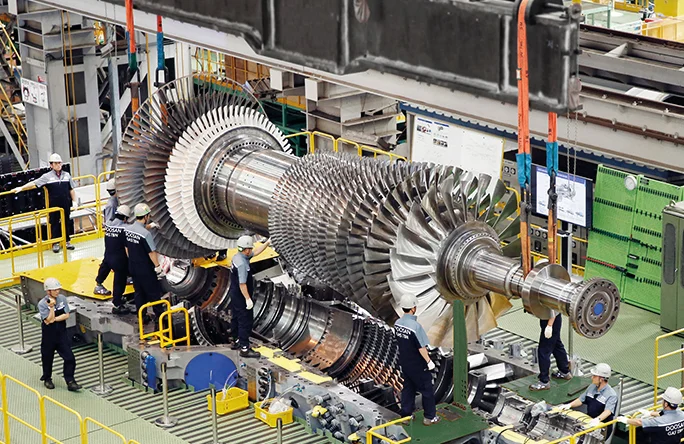

In the field of modern industry and aviation, turbine blades are the key components of the heart of the engine, and with the development of industrial technology and energy efficiency, the performance requirements of key components are becoming higher and higher. In particular, equipment that operates under extreme temperature conditions, such as gas turbines and burners used in aircraft engines, requires materials that can withstand high temperatures and pressures as well as corrosive environments. As an excellent superalloy, Inconel 617 shows incomparable advantages in these fields, especially its superior mechanical properties and corrosion resistance.

Inconel617 Feature Description

- Nickel 617 is an alloy containing chromium (Cr), molybdenum (mo) and cobalt (Co), which has unique physical and chemical properties. As a result, the material has a high heat resistance and can withstand pig operating temperatures of 1093°C (2000°F) without losing the mechanical properties of the pig. In addition, Inconel 617 has excellent oxidation and carbonization properties, and has good stability even in oxidized and reduced atmospheres. Another important advantage of this material is its good welding ability, which makes it easier to create parts in complex forms, providing designers with greater flexibility.

- inconel 617 is suitable not only for static components, but also for dynamic components, as they maintain good strength at high temperatures. This means it can work perfectly under repeated thermal cycle conditions, which is common in many high-temperature applications. In addition, this material is highly resistant to corrosive substances such as sulfides and chlorides, making it ideal for the chemical industry.

Turbine burner design considerations

There are many important factors to consider when designing a turbine burner, including thermal efficiency, emission control, reliability and maintenance costs. Using the Inconel 617 can significantly improve the overall performance of disposable phones. Due to its high temperature, this material allows for a more efficient fuel combustion process, thereby improving the energy efficiency of the entire system. At the same time, high strength and durability reduce service frequency, extend the life of components, and reduce long-term operating costs. Choosing these materials helps companies seeking sustainability reduce resource consumption and have an impact on the environment.

This is a practical example.

- The range of products for turbine burners is used by many large industrial manufacturers to optimize the range of products. For example, in a major power plant project, when 617 critical combustion chamber components were adopted, not only did the operating temperature improve and the combustion process become cleaner, but harmful emissions were also effectively reduced. In addition, some advanced aviation engine manufacturers are attempting to use this material in the design of the next generation of high-performance engines in order to meet the increasingly stringent environmental standards of the aviation sector in the future.

- In practice, the inconel 617 burner has demonstrated good strength and reliability. The inconel 617 burner has for many years been characterized by an extremely low failure rate in continuous service tests and by consistent behaviour under difficult conditions. The use of this material not only improves the safety and lifetime of the equipment, but also reduces maintenance costs and significantly improves overall economic viability.

Innovation and the future.

- As material science developed, researchers sought ways to further improve the efficiency of inconel 617. Properties of alloys can be improved, for example, by clarifying their composition or introducing new processing processes. These efforts are aimed at developing a new generation of high-temperature alloys that are more economical and more efficient in terms of better serving the energy industry of the future. It is expected that new applications based on inconel 617 and its derivatives will be available in the coming years, bringing the sector to a higher level.

- Not only the innovations of the materials themselves, but also production technologies and quality control methods are constantly developing. For example, reinforcement technology (3d printers) has been used to manufacture complex components that have been incorporated into 617, not only reducing production cycles, but also making complex designs that are difficult to implement in traditional production. At the same time, advanced test methods such as computer X-ray (computer axial tomography) are used to ensure that the quality of each component meets the highest standards.

Conclusions and recommendations

Thus, inconnel 617 occupies an important place in the production of turbine burners due to its unique physical and chemical characteristics. Undoubtedly, the choice of inconel 617 is a wise choice for companies that want to innovate and offer optimal performance solutions. Considers that, as science and technology continue to evolve, this material will continue to play an important role in supporting the global transition to cleaner and more efficient energy systems.

Contact us

If you are interested in inconel 617 turbine blade, or have any questions, please feel free to contact us. Our professional team will be happy to provide you with detailed information as well as individual solutions according to your specific needs. We aim to provide quality goods and services that will help you achieve your business goals. We look forward to working with you to create a better future!