An aircraft engine is a highly complex and precise thermodynamic machine. As the heart of an aircraft, it is not only the driving force for flight, but also an important driving force for the development of the aviation industry. Every important change in human aviation history is closely related to the technological progress of aircraft engines. Aircraft engines are known as the “flower of industry” and are high-tech products that are capital and technology intensive. This article will take you through the four essential violent testing tests that must be conducted for the entire aircraft engine.

First: Swallowing test

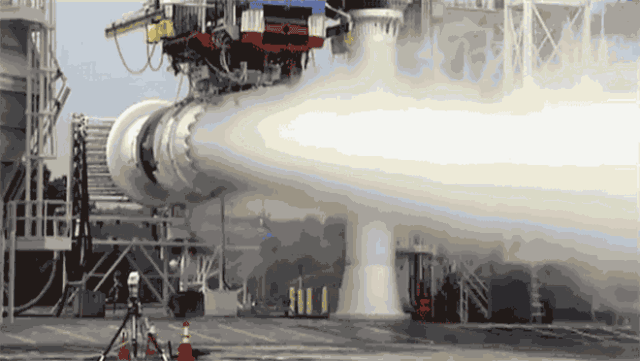

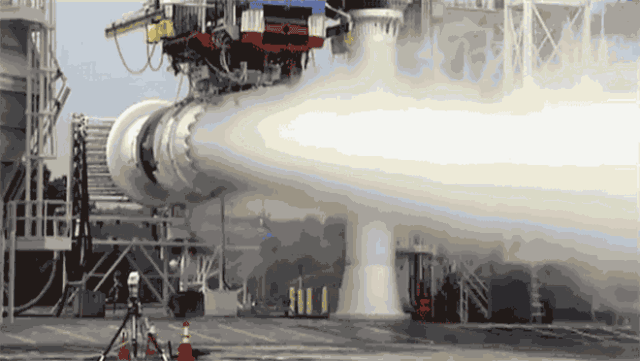

When an airplane flies on rainy days, the engine will ingest liquid water (rainwater) from the atmosphere and water that exists in the form of water vapor in the atmosphere. In addition, if there is rainwater accumulation at the airport, when the aircraft is taxiing on the ground and the engine is close to the ground, the accumulated water on the ground may be sucked into the engine. So aircraft engines must undergo a water ingestion test.

A large number of nozzles are placed in front, spraying 800 gallons (about 3 tons of water) per minute, requiring the aircraft engine not to turn off.

Secondly, hail testing

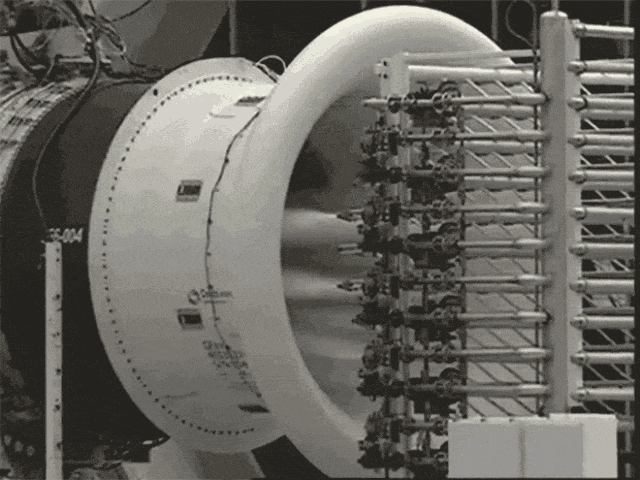

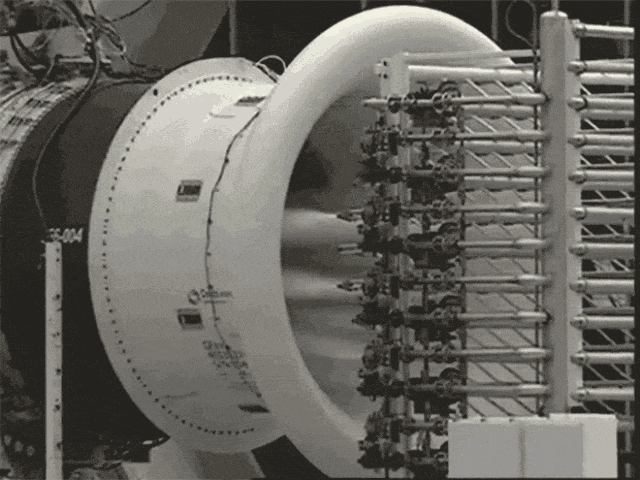

Compared to ice, water is nothing. It is common for airplanes flying at high altitudes to encounter hail and ice during severe weather conditions.

In hail testing, testers need to throw hail and ice cubes manufactured to strict standards into a running engine through specialized instruments for testing.

Thirdly, bird strike test

Everyone knows that flying bird collisions have always had a place in aviation accidents. According to the law of momentum, a collision between a 0.45 kilogram bird and an airplane traveling at a speed of 800 kilometers per hour will generate an impact force of 153 kilograms; A 7-kilogram bird collided with an airplane traveling at a speed of 960 kilometers per hour, with an impact force of 144 tons.

In 2009, a US flight crashed into a bird and made an emergency landing on the Hudson River to ensure the safety of the aircraft engines. In the future, aircraft engine manufacturers will arrange for the “Little Chicken Cannon” to shoot and operate aircraft engines to verify their bird strike resistance.

In the test, bird carcasses collected through regular channels were shot into the engine one by one using a chicken cannon (compressed air cannon).

Fourth: Blade Loss Test

The most extreme test of an aircraft engine is undoubtedly the “blade ejection” test. At a speed of up to 3000 revolutions per minute, a blade is ejected and sweeps through other parts like a shotgun shell to see the impact. In order to conduct this experiment, engineers conducted a small explosion at the bottom of the blades, causing them to fly away and see how the engine looked.

In addition to the above tests, a qualified aircraft engine also needs to undergo torque testing, disassembly inspection, various extreme environmental tests, vibration testing, corrosion testing, thermal fatigue testing, damage tolerance testing, crosswind testing, acoustic testing, and many other processes until it passes the testing standards and is officially applied to the aircraft.