The influence of hot corrosion on the fatigue performance of hot end component materials

Hot corrosion fatigue performance of high-temperature alloys for turbine blades

Many scholars have explored and studied the effect of hot corrosion on the fatigue performance of high-temperature alloys for turbine blades under different conditions. The main method is to pre treat the high-temperature alloy with hot corrosion and then conduct fatigue tests. In most cases, corrosion pit propagation and crack initiation account for the majority of the hot corrosion fatigue life [51]. The fatigue cracks of un corroded specimens often originate from defects near the surface/subsurface of the alloy and propagate inward. The cracks caused by subsurface defects are the main damage mechanism; The crack nucleation of hot corrosion specimens begins at multiple surface locations where corrosion products peel off, and these cracks are usually formed by the merging of microcracks formed during corrosion. The loose corrosion layer and γ ‘deficient layer in the pre hot corrosion sample reduce the surface mechanical properties of the alloy, thereby affecting the initiation process of fatigue cracks [52].

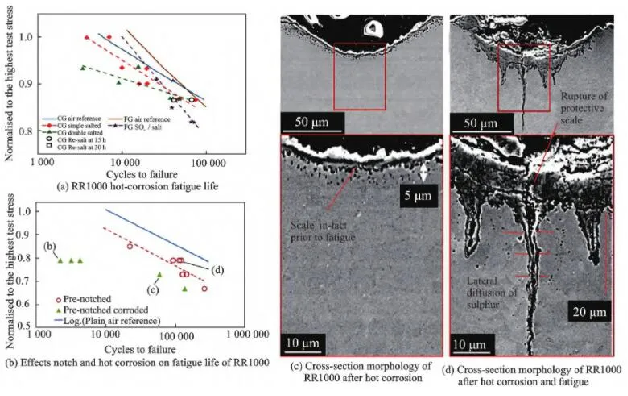

Usually, hot corrosion can reduce low cycle fatigue life by 60% to 98%, and the initiation of fatigue cracks is closely related to the size and spacing of corrosion pits [53]. In addition, load conditions also have an impact on the hot corrosion fatigue behavior. As shown by Brooking et al. [54], when single crystal CMSX-4 alloy is in a low-temperature hot corrosion environment, introducing a 60 second holding load at the peak of fatigue load will reduce its fatigue life, as shown in Figure 7 (a). This is because when fatigue is combined with low-temperature hot corrosion, the long-term holding process can cause cracks to open, allowing corrosive media to diffuse to the crack tip, leading to an increase in the degree of oxidation around the crack tip, accelerating fatigue crack propagation, and ultimately reducing fatigue life. Chapman et al. [55] also found similar results in the study of corrosion fatigue of single crystal CMSX-4 alloy. Yang et al. [39,56] found in their study on the low cycle fatigue behavior of DZ125 alloy after high-temperature hot corrosion that prolonged pre corrosion and prolonged loading during the fatigue process accelerated the corrosion fatigue failure of DZ125 alloy. One of the main causes of corrosion fatigue failure was crack initiation caused by surface corrosion layer cracking, as shown in Figure 7 (b-d). In addition, the low cycle fatigue failure of DZ125 alloy is also related to recrystallization caused by hot corrosion and the reduction of effective area of the specimen. As shown in Figure 7 (e), low cycle fatigue load after high-temperature hot corrosion can cause damage to the protective oxide layer on the alloy surface, promote recrystallization, and form many small grains. Under low cycle fatigue loading, cracks often initiate at these recrystallized grain boundaries. In summary, the decrease in low cycle fatigue life of high-temperature alloys for turbine blades after hot corrosion is closely related to factors such as corrosion pits, defects, formation of oxidation/sulfides, and recrystallization caused by hot corrosion erosion.

Although some experimental studies have been conducted both domestically and internationally on the hot corrosion fatigue performance of high-temperature alloys for turbine blades, they have to some extent revealed the influence of hot corrosion on fatigue failure. However, these experimental studies are mainly based on pre hot corrosion of high-temperature alloys and then conducting fatigue tests [57,58]. The experimental conditions are different from the service environment of turbine materials (i.e. the coupled service environment of gas ocean environment), and cannot reflect the interaction between hot corrosion and mechanical load in real time. Usually, the action of mechanical loads often accelerates the occurrence of hot corrosion, which in turn promotes the initiation and propagation of fatigue cracks in turbine materials under mechanical loads [8,59,60]. Therefore, further research is needed to investigate the fatigue failure mechanism and laws of turbine materials under the coupling effect of hot corrosion fatigue load, and the testing equipment under the coupling effect of gas ocean environment still needs to be developed [61,62,63]. In addition, the current research on the hot corrosion fatigue performance of high-temperature alloys for turbine blades mainly focuses on their low cycle fatigue performance, and there is relatively little research on the hot corrosion high cycle fatigue performance. The effect of hot corrosion on high cycle fatigue failure of high-temperature alloys for turbine blades is also significant [47]. For turbine blades, due to their high service temperature, severe thermal corrosion damage, and exposure to aerodynamic loads, they often experience high cycle vibration fatigue failure. Conducting research on the vibration fatigue failure mechanism and laws of turbine blade materials under the coupling effect of gas ocean environment is of great significance for the fatigue strength/life design of turbine blades, and further research is still needed.

Hot Corrosion Fatigue Performance of Turbine Disk High Temperature Alloy

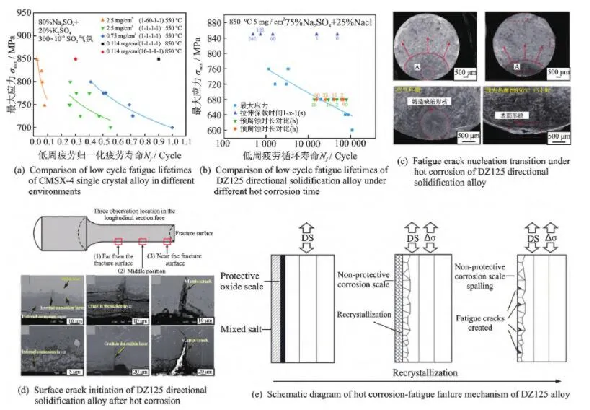

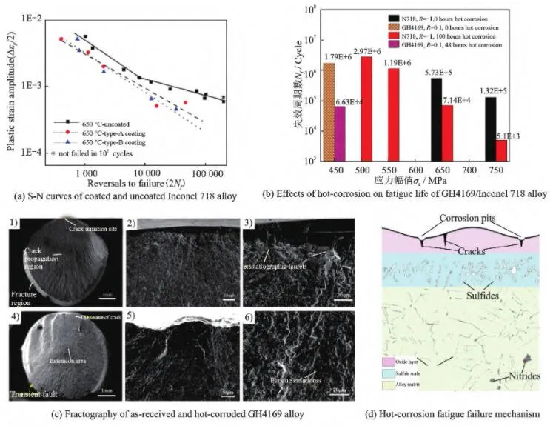

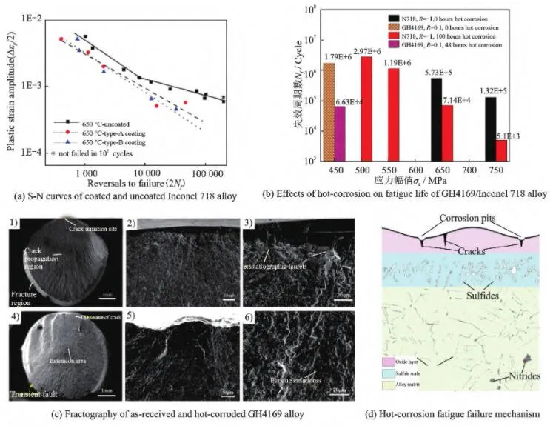

Similar to high-temperature alloys for turbine blades, hot corrosion significantly reduces the fatigue life of turbine disk alloys [64]. As shown in Figure 8 (a), the strain controlled low cycle fatigue life of Inconel718 alloy was significantly reduced after pre hot corrosion in 75% Na2SO4+25% NaCl and 90% Na2SO4+5% NaCl+5% V2O5, especially at lower plastic strain amplitudes, and pre hot corrosion had a greater impact on fatigue life in 90% Na2SO4+5% NaCl+5% V2O5 [43]. After pre heat treatment of Inconel 718 alloy and GH4169 alloy, stress controlled high cycle fatigue experiments were conducted, and it was found that the fatigue life of the preheated corroded samples decreased sharply [49], as shown in Figure 8 (b). For GH4169 alloy that has not undergone hot corrosion, fatigue cracks mainly originate in the slip bands on the surface and then propagate along the {111} slip plane. Similar to other nickel based high-temperature alloys, a large number of cleavage planes can be observed around the crack initiation site [65,66]. For GH4169 alloy after hot corrosion, fatigue cracks mainly originate from the surface hot corrosion layer, and the morphology around the crack initiation zone is relatively smooth, with no crystallographic cleavage planes observed. In addition, it can be seen from the fracture surface that the structure of the hot corrosion layer is relatively loose. Due to the peeling of the hot corrosion layer, pits are formed on the surface of the specimen in the crack initiation zone, as shown in the fifth image of Figure 8 (c). When the crack penetrates the thermal corrosion layer, the fatigue crack propagation characteristics are consistent with the original GH4169 alloy, showing transgranular propagation, and obvious fatigue bands can be observed in the fatigue crack propagation zone. Fracture analysis shows that hot corrosion mainly affects the fatigue crack initiation process of GH4169 alloy, but has no effect on fatigue crack propagation. Therefore, the decrease in fatigue life of GH4169 alloy caused by hot corrosion is mainly related to the fatigue crack initiation process. Figure 8 (d) illustrates the effect of hot corrosion on the fatigue crack initiation process of GH4169 alloy. The factors that affect fatigue crack initiation by hot corrosion include the following aspects:

- Surface hot corrosion layer/oxide layer peeling, reducing the effective bearing area of the specimen and increasing the actual stress.

- The volatilization of chloride leads to the formation of corrosion pits, and the peeling of the surface hot corrosion layer forms protrusions and undulations, causing stress concentration and accelerating the initiation of fatigue cracks.

- Cracks formed in the oxide layer or microcracks already present in the oxide layer propagate into the matrix through the sulfide layer under fatigue loading, ultimately causing fatigue fracture. In this case, due to the short or absent stage of fatigue crack initiation, the fatigue life will be greatly reduced.

- The lower hardness of the vulcanized layer indicates that the deformation in this area may develop more significantly, leading to strain localization and accelerating crack initiation.

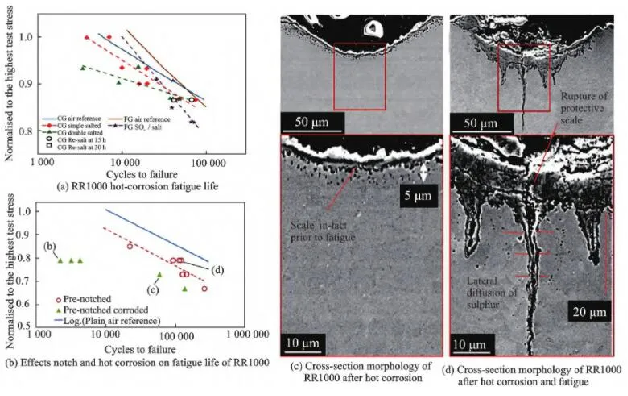

[67] analyzed the effect of low-temperature hot corrosion on the low cycle fatigue behavior of FGH96 alloy at 700 ℃ for powder high-temperature alloys. Research has found that low-temperature hot corrosion causes the fatigue crack initiation location of FGH96 alloy to transition from subsurface defects to surface corrosion pits. The decrease in fatigue life is closely related to the accelerated crack initiation by corrosion pits and the degradation of grain boundary properties. Child et al. [68] studied the thermal corrosion fatigue behavior of RR1000 alloy with coarse and fine grains under different concentrations of corrosive media. As shown in Figure 9 (a), in an environment rich in SO2, the fatigue life of both coarse-grained and fine-grained RR1000 alloys is reduced under standard concentration corrosive media and single pre hot corrosion conditions. Pre hot corrosion was carried out on the coarse-grained RR1000 alloy in a corrosive medium with twice the standard concentration, and it was found that as the stress decreased, the magnitude of fatigue life reduction caused by hot corrosion decreased. In addition, during the hot corrosion process of some coarse-grained RR1000 alloy samples, after intervals of 15 and 30 hours respectively, the addition of corrosive medium was supplemented. The results showed that supplementing the corrosive medium at the specified time interval did not seem to affect the fatigue performance at the lowest stress level.

Powder et al. [69] also investigated the hot corrosion low cycle fatigue behavior of RR1000 alloy with notches. Figure 9 (b) shows the fatigue life data of smooth specimens, notched specimens, and notched+pre corroded specimens. Due to the stress concentration effect of the notch, the fatigue life of the notch specimen is reduced compared to the smooth specimen under all test load conditions. The fatigue test results of notch+pre hot corrosion specimens show that under the same stress level, hot corrosion significantly reduces the fatigue life of notch specimens, and the higher the stress level, the greater the degree of fatigue life reduction, with a reduction range of 1-2 orders of magnitude. Figures 9 (c, d) indicate that during the fatigue cycle, the rupture of the protective surface oxide layer exposes the sulfide containing matrix material and further oxidizes it. As sulfides oxidize, the concentration gradient on the surface causes the released sulfur in the solid solution to diffuse downwards along the grain boundaries, further reacting with Cr and Ti elements, resulting in the formation of new sulfides along the grain boundaries. When the stress level is high enough, grain boundary sulfurization/oxide cracking occurs, causing grain detachment and accelerating crack initiation and propagation.

Gabb et al. [70,71] studied the fatigue performance of ME3 alloy strengthened by surface shot peening after hot corrosion. The research results show that for ME3 alloy without shot peening strengthening, hot corrosion reduces the low cycle fatigue life by 60% to 98%, and the initiation of fatigue cracks is closely related to the size and spacing of corrosion pits. In addition, temperature also has an impact on the initiation of fatigue cracks under hot corrosion. At high temperature (704 ℃), cracks initiate along the grain boundaries around the corrosion pit, while at low temperature (204 ℃), cracks originate from the grain boundaries at the bottom of the corrosion pit. Shot peening reduced the impact of mild hot corrosion at 204 ℃ on fatigue life, but in severe hot corrosion ME3 alloy, the effect of shot peening strengthening on suppressing fatigue damage was not significant. Analysis suggests that shot peening can form residual compressive stress on the surface of the specimen, which can alleviate the impact of corrosion pits on fatigue life. However, due to fatigue cracking at the corrosion pit, prolonged corrosion time and fatigue at high temperatures can still significantly reduce the fatigue life of shot peened specimens. In addition, Smialek et al. [72] studied the effect of hot corrosion on the fatigue life of LSHR alloys with Cr2AlC coatings. The research results showed that after hot corrosion, the life of uncoated alloys decreased by about 93% compared to untreated alloys, while the life of coated alloys decreased by only about 15%, indicating that Cr2AlC coatings are beneficial for resisting hot corrosion fatigue damage.