Aerospace: In the turbine components of aircraft engines, it ensures reliability and high performance in harsh operating environments.

Industrial gas turbines: Provide high-quality turbine accessories for various industrial gas turbines, adapting to high temperature and high pressure conditions.

Power generation: Used in turbine systems of some gas-fired power generation equipment to ensure power generation efficiency and stability.

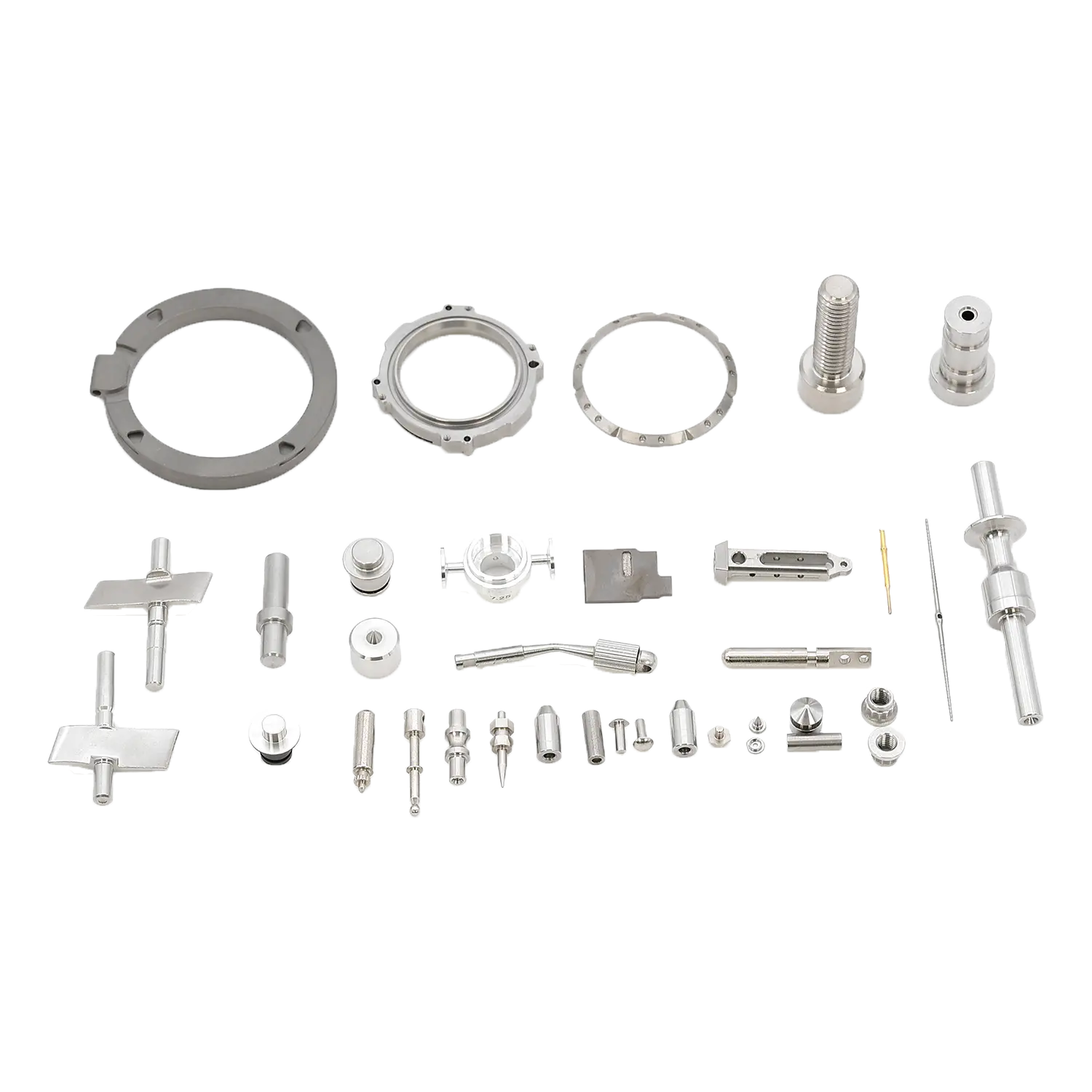

Precision component used during turbocharger assembly to maintain proper alignment and spacing between housing parts, ensuring correct tolerances and preventing damage.

Mechanical shaft connecting the turbocharger’s actuator to the wastegate valve, controlling boost pressure by regulating exhaust gas flow through the turbine.

Aerodynamic vanes in the turbine and compressor wheels that spin at high speeds to compress intake air and extract energy from exhaust gases.

Cylindrical pin with multiple diameters and helical grooves (hobbed threads), used for precise alignment, positioning, or fastening in mechanical assemblies.

Cylindrical spacer used to maintain precise distances between gauge components or measurement instruments, ensuring accurate calibration and proper sensor positioning.

Precision pin that establishes exact positioning of gauges or measuring instruments, ensuring consistent placement and accurate readings during inspection or assembly processes.

Thin, flat component machined to exact tolerances used to fill small gaps, adjust spacing, or achieve precise alignment between mating parts.

Highly-engineered valve component built to stringent nuclear industry standards, designed for extreme reliability, radiation resistance, and leak-tight performance in reactor systems.

Lightweight mounting bracket designed to hold optical windows or lenses in 5G telecommunications equipment, featuring minimal material thickness for weight reduction.

Protective conduit that houses and shields fiber optic cables in communication systems, safeguarding delicate glass fibers from physical damage and environmental factors.

The movable magnetic component inside a solenoid valve that responds to electromagnetic force, shifting position to open or close fluid flow passages.

Tiny precision-drilled openings used in medical devices for controlled fluid delivery, aerosol generation, or minimally invasive procedures requiring exact flow rates.

Precision titanium components manufactured through advanced turning and milling processes, combining high strength-to-weight ratio with superior corrosion resistance for demanding aerospace and industrial applications.

Corrosion-resistant sensor housing engineered for harsh petrochemical environments, utilizing advanced materials and protective coatings to ensure reliable long-term performance and sensor accuracy.

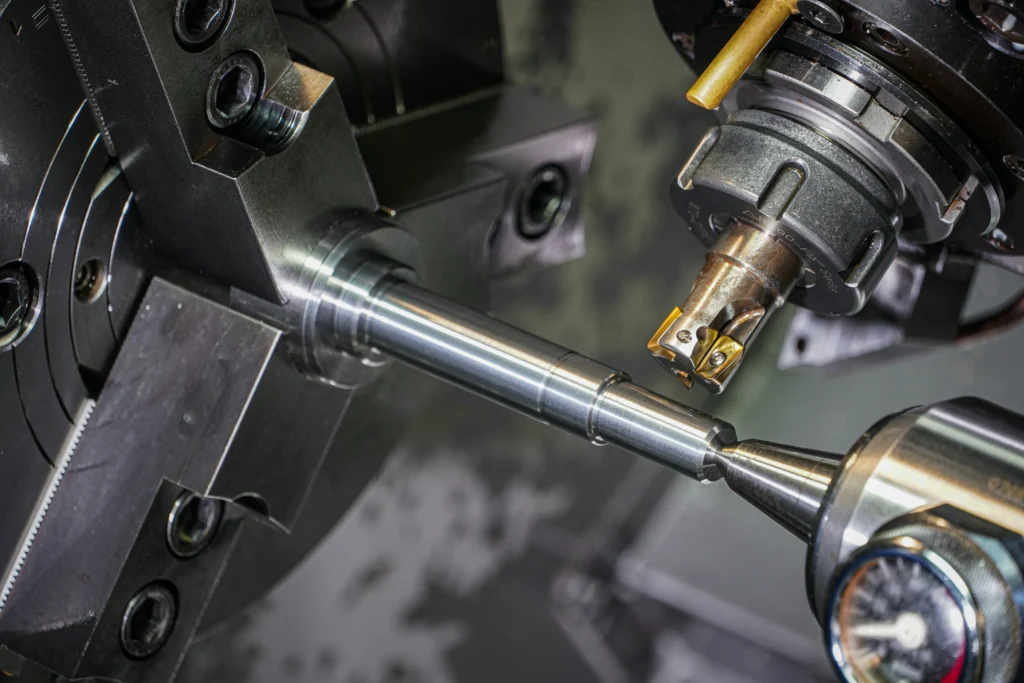

According to the requirements of the turbine working environment, select suitable high-temperature alloys or other special metals as materials.

The machining of turbine parts requires highly precise machine tools and tools to ensure the accuracy of dimensions and surface quality.

The heat treatment process can improve the heat resistance and strength of the material, while surface treatment can improve the corrosion resistance and surface finish of the parts.

Dynamic balancing of rotating parts such as turbine impellers is a key step to ensure the stability and safety of turbine equipment when running at high speeds.

Part numbers alone are not sufficient to ensure performance.

To guarantee precision and compatibility, please provide:

Drawings or used samples for reverse engineering.