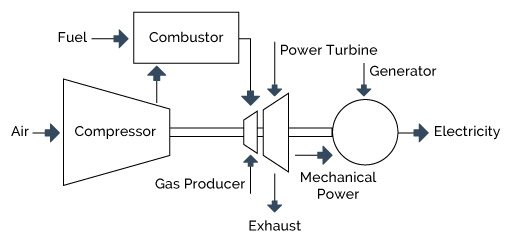

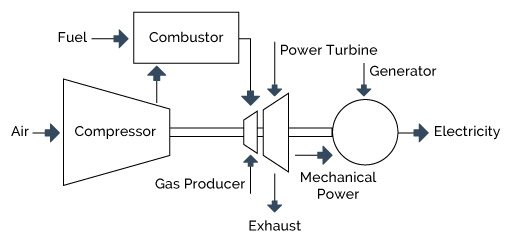

Aeroengine has many parts, its performance and reliability are important for flight safety, do you know how many parts it has? Xiaobian said that the aircraft engine parts mainly include compressors, combustion chambers, turbines and jets, etc., due to the high requirements of the aircraft engine itself, there are also some difficulties to overcome in the manufacturing process.

Main components and manufacturing difficulties of aero engine

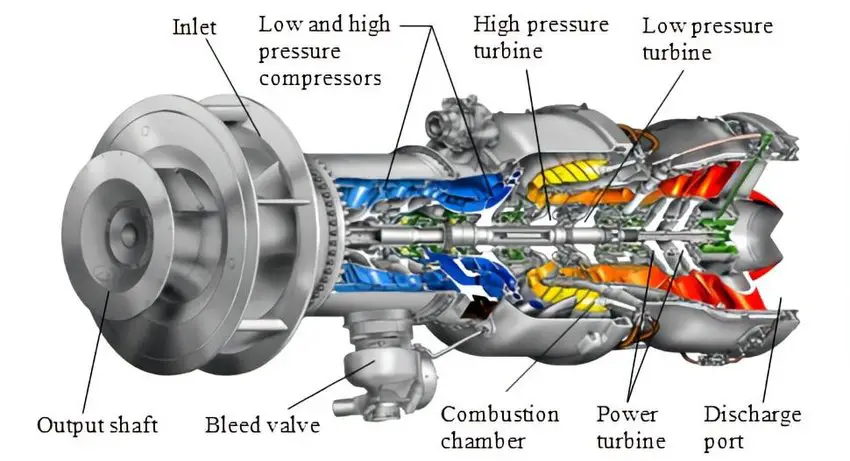

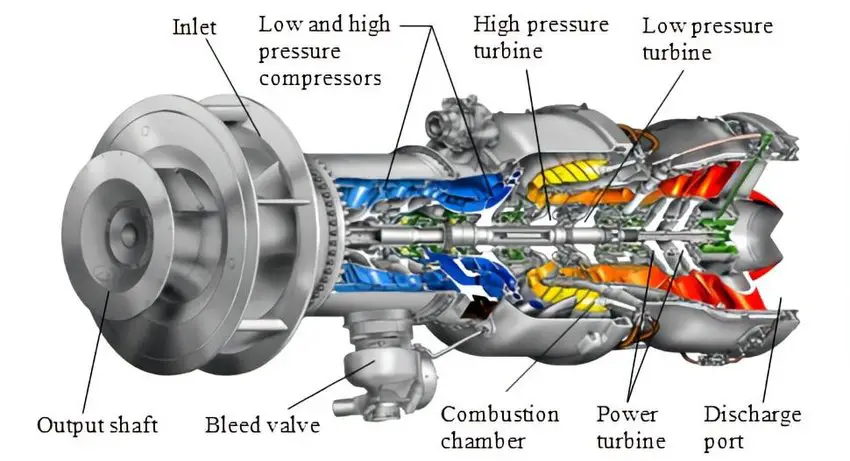

1.the compressor is one of the important components of the aircraft engine, it can compress the air and send it to the combustion chamber for combustion. Since the speed and pressure of the air when entering the compressor are very high, the manufacture of the compressor needs to meet very high precision and quality.

At the same time, predicting and simulating the movement of air under different pressures also requires advanced scientific technology and computing power. The manufacture of compressors is very difficult, but it is precisely because of its high accuracy and reliability that it can operate stably in extremely harsh environments at high altitudes.

2. the combustion chamber is another component worth saying in the aircraft engine parts. The combustion chamber is the place where the combustion process is realized, in which the space and time of combustion accumulation and the flow of temperature distribution in the furnace are affected by very subtle changes in the air flow, making the combustion chamber extremely difficult to manufacture.

Due to the high temperature and pressure in the combustion chamber, it is necessary to use alloy materials that can withstand high temperature and high pressure for manufacturing. Combustion chamber manufacturing technology is also a major difficulty in aero engine manufacturing technology.

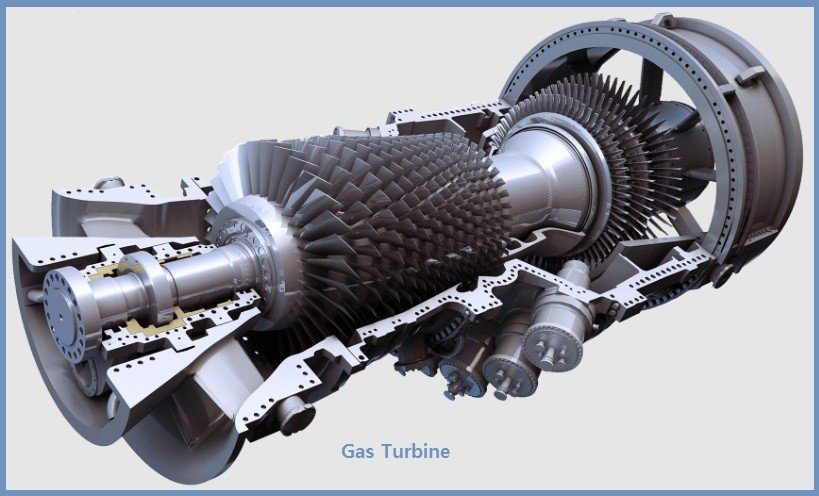

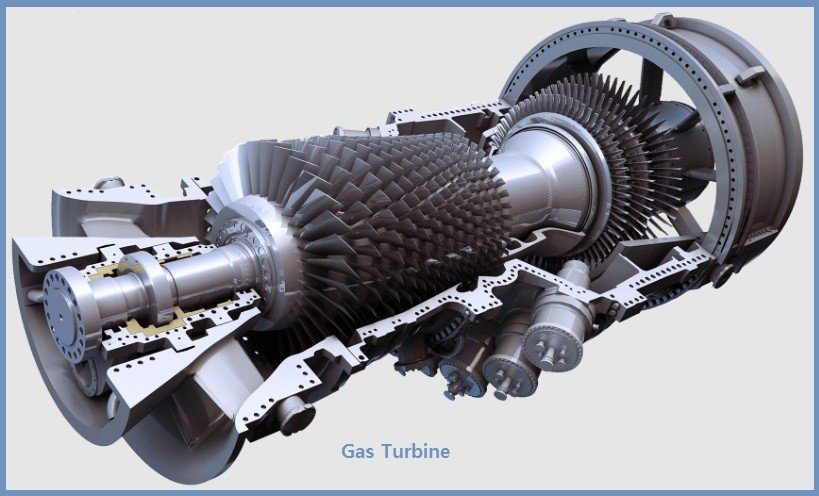

3.the turbine is an important part of converting the high temperature and high pressure gas in the combustion chamber into power. The turbines must also be made of heat-resistant alloy materials that can withstand high temperatures and pressures.

The manufacture of the turbine also requires high precision and craftsmanship to ensure that the turbine does not become unbalanced and does not fall off when spinning at high speeds.

4.the jet nozzle is another important part of the aircraft engine. The jet nozzle can shoot a high-speed stream of high-temperature and high-pressure gas through the diffuser to generate thrust.

In order to improve the efficiency of the nozzle, the manufacturing of the nozzle requires special alloy materials and precision machining processes to ensure that the nozzle will not deform or fall off under high temperature and pressure.

Aero engine parts are many, each part has its processing and manufacturing difficulties, for manufacturers, each link of manufacturing can not be careless, whether it is material, process or engineering design and calculation analysis should be taken seriously, of course, it is precisely because of its manufacturing requirements are relatively high, so that the aero engine in terms of performance is guaranteed. Making flying safer.

What problems should we pay attention to when customizing aircraft parts?

Aviation aircraft design and manufacturing is very detail-oriented, many times, in order to ensure the performance and safety of the aircraft, many parts need to be specially customized, different aircraft types, parts customization requirements are not the same, for the first time for aviation aircraft parts customization staff, there may be a lot of confusion. The following small series has compiled a piece of information, I hope that after reading this information, you can know what problems need to pay attention to customization.

1.compliance issues:Aviation aircraft is a highly safety-related industry, so aviation accessories must comply with the appropriate laws and regulations and aviation standards. At the same time, it is necessary to understand the requirements of the customer or the manufacturer to ensure that the customized parts are consistent with the design and use of the customer. A detailed understanding of relevant regulations and standards is required before customizing accessories in order to better meet the needs.

2.material selection:Aviation aircraft often need to operate for a long time under harsh conditions, so it is necessary to use high-performance materials such as high strength, high corrosion resistance, high temperature resistance and wear resistance. The choice of accessory materials directly affects the use effect and flight safety of the entire aviation aircraft. The selection of high-quality materials is a necessary condition for the customization of aircraft accessories.

- 3.precision and quality issues:In the manufacturing process of accessories, great attention needs to be paid to precision and quality issues. Because even a small component difference can have an impact on the performance and safety of the aircraft. When customizing accessories, it is necessary to pay attention to the quality standards and strict accuracy requirements of the parts to ensure that the accuracy of the parts matching is highly recognized.

- 4. reliability issues:The relevant reliability factors should be considered in the customization of aircraft parts. For example, to reduce the possibility of incorrect assembly of parts, the use of mature production processes and quality assurance systems, regular inspection and maintenance. These technologies should also be understood and applied when customizing accessories to ensure that they remain stable and reliable during the flight.

5. Cost issue

The issue of cost is undoubtedly one of the most important issues to consider when customizing aviation accessories. The cost can be reasonably determined based on the precise definition of the factors required by the customer. At the same time, it is also necessary to understand the price of materials and manufacturing processes and other conventional communication costs, and ensure that cost and quality balance.

In the customization of parts, we must consider the cost issue, but we can not ignore other factors such as the quality of parts, and can not reduce manufacturing costs at the expense of the quality and safety of aviation aircraft.

There are many details that need to be paid attention to in the customization of aviation aircraft parts, which not only involves compliance issues, material selection, but also needs to take into account the accuracy, quality reliability and cost issues, through repeated verification and confirmation, you can get the parts that meet the actual requirements of use, and the manufacturing of aviation aircraft is more smooth.

Thank you for your interest in our company! As a professional gas turbine parts manufacturing company, we will continue to be committed to technological innovation and service improvement, to provide more high-quality solutions for customers around the world.If you have any questions, suggestions or cooperation intentions, we are more than happy to help you. Please contact us in the following ways:

- WhatsAPP:+86 135 4409 5201

- E-mail:peter@turbineblade.net