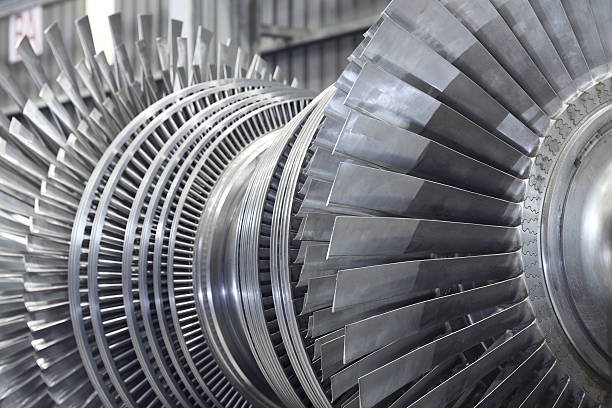

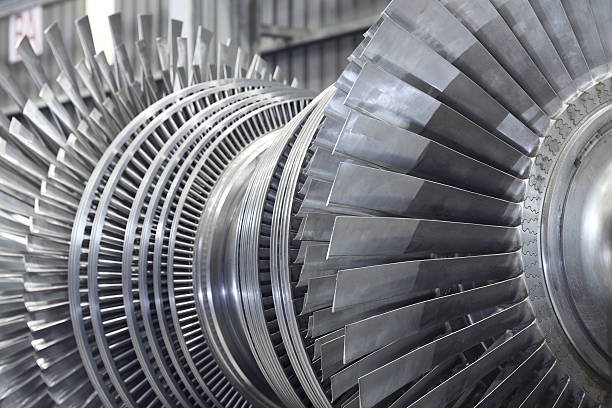

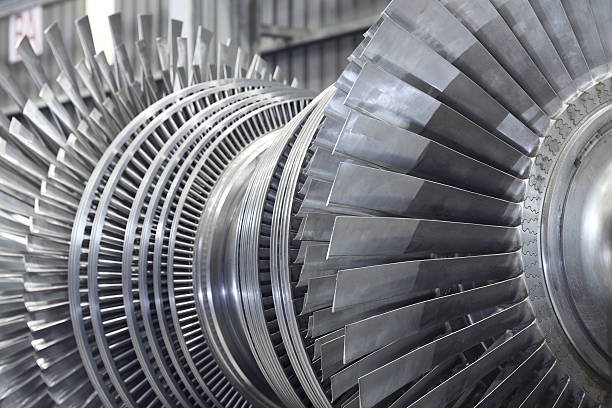

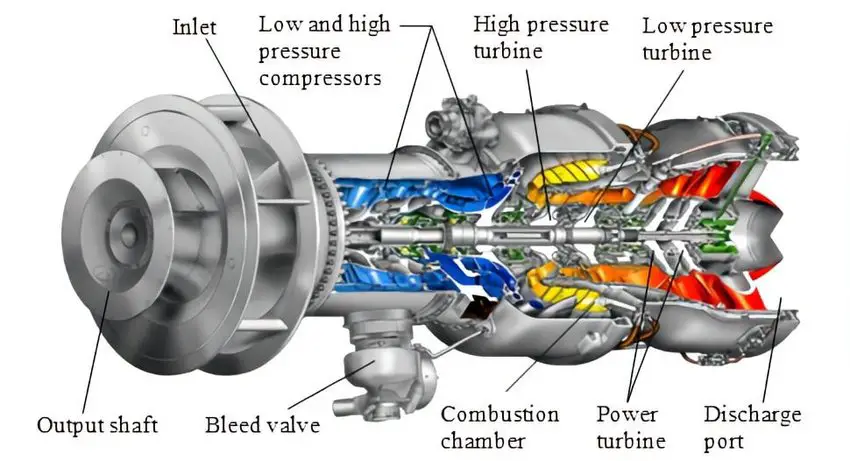

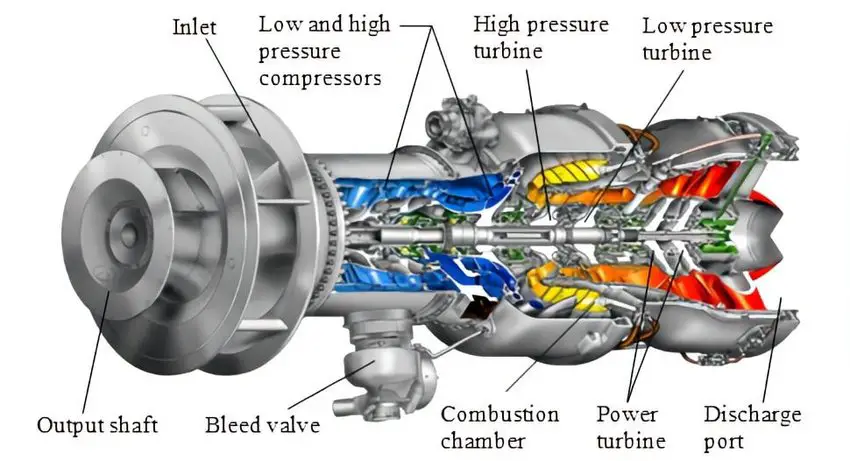

Superalloy, also known as heat-resistant alloy or super alloy, is an essential metal material for modern aviation engines, rocket engines, gas turbines and chemical equipment. It can withstand complex stress under oxidation and gas corrosion conditions of 600 ~ 1100℃, and can work reliably for a long time.

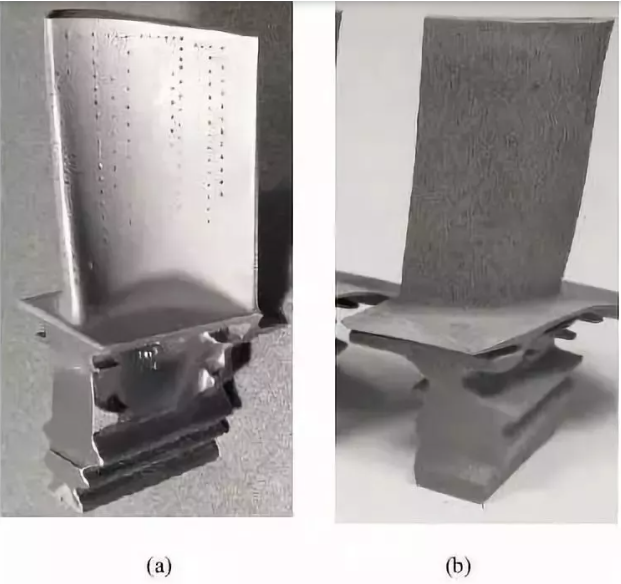

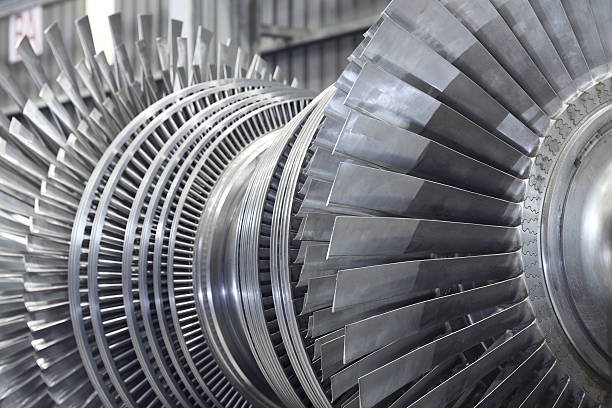

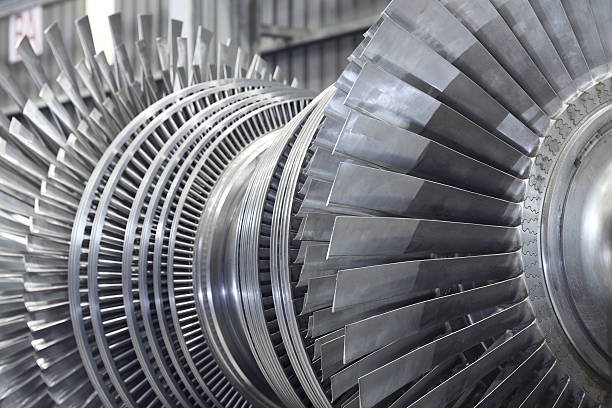

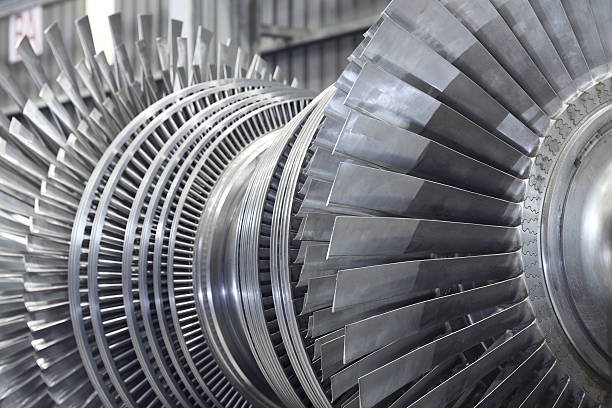

At present, among the deformation superalloys, the most widely used are iron based superalloys and nickel based superalloys. Iron-based alloys are used more as turbine discs, compressor discs, bearing ring combustion chambers and blades, and their composition characteristics are mainly iron, containing a large amount of nickel, chromium and other elements. According to its strengthening characteristics, it can be divided into weak age hardening type, solid solution hardening type, carbide age hardening type and intermetallic compound age hardening type.

Nickel-based alloys are more used in the manufacture of turbine blades, combustion chambers, turbine discs, compressor discs and compressor blades, whose composition is characterized by nickel base, containing ω (Cr) of 10% to 20%, forming nickel-based austenite matrix. In addition, some alloys also contain 10% to 20% of ω (Co), forming a nickel-chromium-cobalt austenite matrix. According to its strengthening type, it can be divided into solid solution strengthening type and aging strengthening type.

The properties of superalloy mainly depend on the composition and microstructure of the alloy. The type, structure, shape, size, quantity and distribution of precipitated phase are particularly important in the microstructure. Common precipitates in iron – and nickel-based alloys are intermetallic compounds, carbides and borides. All of these compounds can be regulated and controlled by heat treatment, and their morphology and distribution can also be changed by deformation.

The heat treatment of deformed superalloys generally consists of solid solution treatment, intermediate treatment (also known as secondary solid solution treatment) and aging treatment. The purpose of solution treatment is to obtain uniform supersaturated solid solution and control the appropriate grain size. The purpose of intermediate heat treatment is to change the state of carbide and obtain two different γ ‘phases with different sizes. The purpose of aging treatment is to make the strengthened phase fully and evenly precipitate, to achieve the effect of precipitation hardening, the selection of temperature, time and frequency, to get the number of strengthened phase, shape and distribution is appropriate as the criterion. The core of the hot deformation process of deformed superalloys is the process plasticity and critical deformation of coarse crystals.

1.Characteristics of superalloy deformation

1)Low plasticity, superalloy due to the high degree of alloying, has a heterogeneous structure and complex phase composition, therefore, the process plasticity is low. Especially at high temperatures, when the impurity elements such as S, Pb, Sn are contained, the binding force between grains is often weakened and the plasticity is reduced. Superalloys generally use the total content of strengthening elements aluminum and titanium to determine the level of plasticity, when the total content is ≥6%, the plasticity will be very low. The process ductility of nickel based superalloy is lower than that of iron based superalloy. The process plasticity of superalloys is very sensitive to deformation rate and stress state. Some alloy ingots and intermediate billets need to be formed by low-speed deformation and upsetting, rolling, and even extrusion.

2)Large deformation resistance, due to the complex composition of superalloy, high recrystallization temperature, slow speed, has a high deformation resistance and hardening tendency at deformation temperature, deformation resistance is generally 4 to 7 times that of ordinary structural steel.

3)The forging temperature range is narrow, the melting point of superalloy is low compared with steel, and the heating temperature is too high to cause overheating and overburning. If the forging stop temperature is too low, the plasticity is low, the deformation resistance is large, and the cold and hot mixed deformation is easy to cause the forging to produce uneven coarse crystals. Therefore, the temperature range of superalloy forging is very narrow, generally only about 200 ° C. The forging temperature range of nickel-based heat-resistant alloys is narrower, most of them are 100 ~ 150 ° C, and some are even less than 100 ° C.

4)The thermal conductivity is poor, and the thermal conductivity of superalloy at low temperature is much lower than that of carbon steel, so it is generally necessary to slow preheat in the range of 700 ~ 800 ° C, otherwise it will cause great temperature stress, so that the heating metal is in a brittle state.

2.Process plasticity of superalloy

1)Due to the addition of a large number of alloying elements, the heat resistance of superalloy is improved, but the process plasticity is greatly reduced. High alloying results in severe segregation and coarse columnar crystals. At the weak link of primary dendrite grain boundary, cracks are easy to occur along the grain boundary. Due to dendrite segregation, the content of alloying elements in the first crystallized part is low, and the content of alloying elements in the dendrite edge part is high, so the carbides and intermetallic compounds are concentrated in the dendrite edge part, which reduces the malleability of the alloy.

2)High alloying makes the plasticity of the superalloy bar much lower than that of the ordinary alloy steel. Because a large number of alloying elements are enriched in the grain boundary region, the grain boundary strength is lower than the intra-grain strength at high temperature, and many of the strengthened phase particles are not all dissolved into the solid solution within the deformation temperature range, such as carbide and boride, etc., so that in addition to γ, there are also strengthened phases involved in deformation, that is, the deformation is not carried out in a single-phase state. Therefore, the process plasticity of superalloy rolling rod is also relatively low. Therefore, in the formulation of superalloy forging process procedures, the process plasticity of the alloy must be measured first.

3.Determination of deformation temperature of superalloy

1)The principle of determining the deformation temperature of superalloy, due to the complexity of the alloying degree of superalloy, the initial melting temperature of the alloy decreases, and the dissolution temperature of recrystallization and strengthening phase increases, resulting in the deformation temperature becoming narrower and narrower. Therefore, when determining the deformation temperature, in addition to ensuring the process plasticity and meeting the forming, it must also meet the need to obtain good organization and properties. In order to keep the cellular dislocation network in the microstructure of superalloy forgings and obtain fine and uniform grains and good properties, the forging deformation temperature should be lower than the grain growth temperature, and the final forging temperature should be close to (slightly higher) the temperature of the second phase particle dissolution into the solid solution and the recrystallization temperature.

2)The heating specification of superalloy, superalloy heating is divided into preheating and heating two stages. In order to shorten the holding time of superalloy at forging heating temperature, avoid excessive grain coarsening and alloying element depletion; At the same time, in order to reduce the thermal stress caused by the poor thermal conductivity and high thermal expansion coefficient of the superalloy, the blank should be preheated before forging. The preheating temperature is 750 ~ 800℃, and the holding time is calculated as 0.6 ~ 0.8min/mm. The heating temperature is generally 1100 ~ 1180 ° C, and the holding time is 0.4 ~ 0.8min/mm. The heating equipment can use a resistance furnace, equipped with a thermometer and an automatic adjustment temperature control device for accurate control. When the flame furnace is selected, the sulfur content in the fuel should be strictly controlled: the sulfur content in diesel or heavy oil should be less than 0.5%; The sulfur content of the gas should be less than 0.7g/m3. The excessive sulfur content in the fuel will form Ni-Ni3S3 eutectic with low melting point (≈650℃) when it penetrates into the surface of the billet, making the alloy hot brittle. It is necessary to take less and no oxidation heating measures to avoid the depletion of chromium, aluminum, titanium and other elements on the surface of the blank, and reduce the fatigue strength and high temperature lasting strength of the alloy. Local induction heating can be used in preforging of blank. Before heating, the blank should be cleaned to remove dirt and avoid surface defects due to corrosion. When forging with multiple fires, the forging heating temperature should be reduced with the extension of the interval time between the two fires to avoid the grain growth that has occurred static recrystallization, at the same time, the reheating temperature should also be lower with the closer to the finished forging product, the smaller the deformation.

4.Determination of deformation degree of superalloy

1) The principle of determining the degree of deformation of superalloys

Due to the high degree of alloying, the deformation temperature range of superalloy is narrow, and there is not much adjustment margin. In addition, the superalloy has no isomerization transition, and the grain size of the alloy is mainly controlled by the forging deformation. Therefore, after the deformation temperature is determined, the choice of deformation degree is very important. At a certain forging temperature, the deformation of each heating order should be greater than the critical deformation degree and smaller than the corresponding deformation degree of the second grain growth region. Under the premise of meeting the requirements of process plasticity and process arrangement (pre-forging), each deformation should be deep and uniform, and try to avoid uneven deformation, otherwise it will produce banded coarse crystals and local coarse crystals. The coarse crystals of superalloys have a certain genetic stubbornness, and it is difficult to change the coarse crystals produced by a single non-uniform deformation when the deformation degree is not large enough in the immediate deformation. In order to obtain satisfactory microstructure and properties, lower heating temperature, larger deformation degree, precipitation phase should be used to control microstructure, improve grain size and grain boundary state during final forging deformation.

In addition to grain size, grain boundary state is also an important microstructure factor. From the point of view of grain boundary strengthening and toughening, the control of grain boundary organization has the following laws:

- (1) The lack of precipitation phase at the grain boundary is easy to become a crack channel.

- (2) The coarse γ ‘phase and carbide are uniformly distributed on the grain boundaries, which will strengthen and toughen the alloy grain boundaries.

- (3) There are stress relaxation parts in the grain boundary depleted zone, which can reduce shear resistance and expand the area of strain concentration. Therefore, when the grain boundary strength is too high, the depleted zone plays a beneficial role.

- (4) The formation of continuous thin film carbide phases on the grain boundary makes the alloy notch sensitive.

- (5) The formation of cellular carbides on the grain boundaries has an adverse effect on the strength and toughening of alloy grain boundaries.

- Therefore, in addition to a reasonable heat treatment system, in the forging process, through a reasonable distribution of deformation, especially to increase the degree of final forging deformation of the last fire, to improve the grain boundary state, grain and grain boundary strength matching, to obtain good organizational properties, is undoubtedly very important.

2)Generally deformed superalloys are more sensitive to critical deformation, and the critical deformation degree usually varies within a wide range (0.5% ~ 20%), the specific value varies with the alloy, and the critical deformation degree of the same alloy is different at different heating temperatures. For example, the total critical deformation degree of GH4049 alloy is 0.1% ~ 7%. The total critical deformation degree of GH4220 alloy is 0.6%-4.7% at 1150℃ and 0.1%-3% at 1180℃, but the critical deformation degree at different forging temperatures, the deformation degree at the maximum grain and the maximum critical deformation diameter are not the same. The diameter of the critical deformation coarse crystal is several orders of magnitude larger than that of the normal grain, with the largest being 10mm and the smallest being 1mm.

5.Influence of forging process parameters on microstructure and properties of superalloy

The proper choice of forging and subsequent heat treatment process parameters directly affects the mechanical properties of forgings. The test results of various alloys are listed below for reference in the selection of heating processing parameters.

1) Effect of heating temperature on microstructure and properties of GH2036 alloy

The allowable heating temperature of GH2036 alloy turbine disk before die forging is 1190℃. If the alloy is heated at 1220℃ for 2h, the tensile and impact samples change from transgranular fracture to intergranular fracture, that is, the alloy overheats. If the alloy is heated for 2h at 1250℃ and 1280℃, the grain boundary of the alloy produces local initial melting, that is, the alloy is overburned. Intergranular fracture occurs in both tensile and impact specimens, and the overall properties of the alloy decrease. Influence of high temperature heating on the properties of GH2036 alloy, the impact, tensile and durable properties of the alloy deteriorate with the increase of heating temperature.

2) Effect of final deformation temperature on the properties of GH4169 alloy

When the final deformation degree is 25%, the notch sensitivity can be eliminated by controlling the final deformation temperature at 900 ~ 955℃, and the increase of the final deformation temperature will make the grain of the alloy become uneven and reduce its plasticity, resulting in notch sensitivity. 3) Influence of grain size on performance

3)Effect of grain size on properties

The coarser grain can increase the lasting strength and creep strength, while the finer grain can increase the yield strength and fatigue strength. Uniform grain size is beneficial to the properties of the alloy. The fracture life of coarse crystals is shorter than that of fine crystals. The comprehensive effect of grain size on the properties of GH4169 alloy shows that the yield strength and fatigue strength of GH4169 alloy are obviously improved by grain refinement, but the fatigue strength at temperatures above 600℃ is decreased. The influence on the permanent strength of the alloy depends on the fracture form (transgranular or intergranular fracture), that is, the temperature of the alloy is related.

4) Influence of thermal process parameters on dynamic recrystallization

When the deformation degree is greater than 30%, when GH4169 alloy is forged on the hammer or hydraulic press, the dynamic recrystallization starting temperature is roughly between 930 ~ 960℃, and when isothermal forging, it is roughly 930 ~ 940℃.

The dynamic recrystallization of GH4169 alloy is facilitated by increasing forging temperature, increasing deformation degree, adopting higher or lower strain rate and applying multiple deformation.