Steam turbines, gas turbines, and internal combustion engines are all types of engines (mechanical devices that generate power). Their ultimate goal is to generate power (for different needs). Their differences mainly lie in their operating principles, sizes, and application scenarios. There is no saying that one is better or worse.

Different operating principles

The most basic operating principle of an engine is to convert chemical energy (coal, oil, gas, etc.) into mechanical power to drive the load through combustion and other methods. Therefore, the engine can be roughly divided into two parts according to the working process: the combustion system and the power system.

If the combustion system and the power system are separate, that is, the chemical energy is burned first and then the medium is used to push the energy to generate power, this engine can be called an “external combustion engine”; on the contrary, if the energy is generated directly during combustion, this engine can be called an “internal combustion engine”.

External combustion engines include what are commonly known as steam turbines and gas turbines, and internal combustion engines include what are commonly known as diesel engines and gasoline engines.

External combustion engines generally perform rotational motion, that is, the medium drives the turbine blades to rotate at high speed.

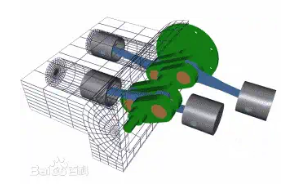

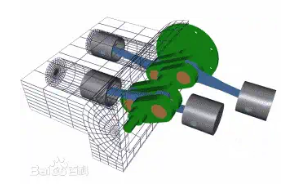

Internal combustion engines generally perform reciprocating motion, that is, directly pushing the piston (intake → compression → power → exhaust) to perform reciprocating motion.

On old tractors and motorcycles, you can clearly hear the engine sound of “clang, clang, clang, clang” or “thump, thump, thump, thump”, which is the sound of the reciprocating motion (back and forth collision) of the internal combustion engine (diesel & gasoline engine).

The main difference between a steam turbine and a gas turbine lies in “steam” and “gas”, that is, the medium that drives the turbine blades to rotate at high speed is different: the medium of a steam turbine is high-pressure steam (water), and the medium of a gas turbine is compressed gas (gas).

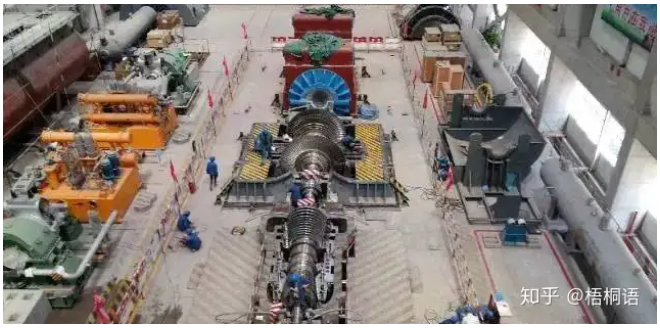

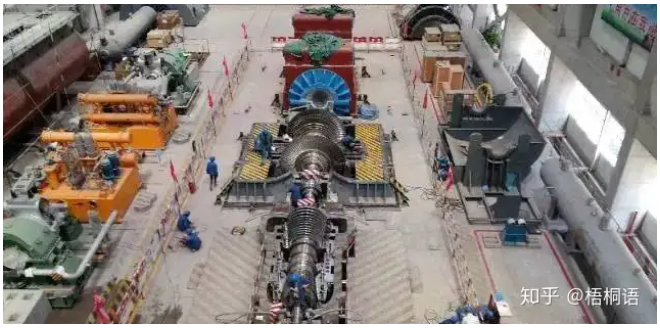

The steam turbine first burns chemical energy to produce high-temperature and high-pressure steam. After the boiler steam enters the turbine, it passes through a series of nozzles and other systems and is finally sprayed onto the turbine blades, causing the turbine rotor equipped with rows of blades to rotate at high speed, thereby generating power.

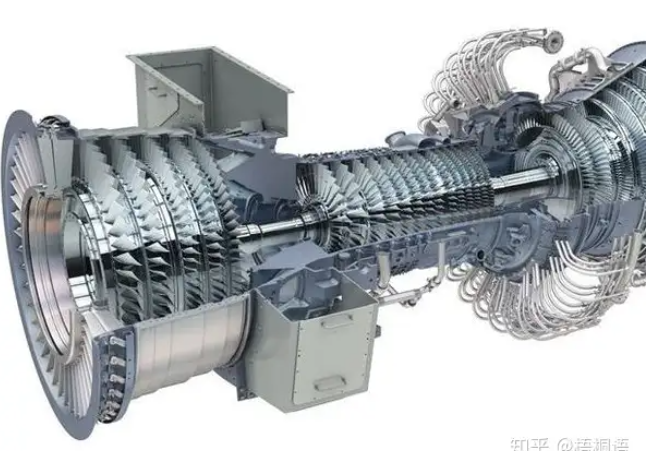

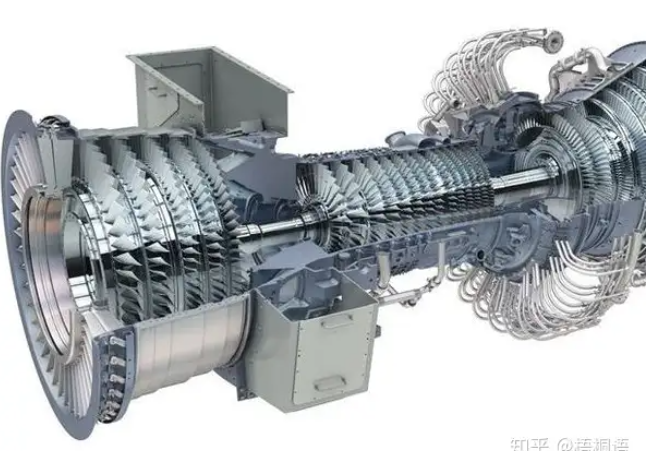

After burning chemical energy, the gas turbine continuously draws in air from the atmosphere through the compressor and compresses it. The compressed air enters the combustion chamber, mixes with the injected fuel and burns to form high-temperature gas, which enters the gas turbine to expand and do work, pushing the turbine blades and the compressor impeller to rotate at high speed, thereby generating power. Note that the unit capacity of high-temperature and high-pressure gas to do work is significantly improved, so a smaller engine can generate greater power.

Difference in size

If you understand the difference in the above working principles, you can easily think that, although both of them burn chemical energy first, steam turbines are used to produce high-temperature and high-pressure steam, while gas turbines directly compress air. Obviously, steam turbines are larger in size, while gas turbines start faster.

Unlike these two external combustion engines, the internal combustion engine directly generates power through combustion explosion in the high-pressure combustion chamber inside the cylinder, so the internal combustion engine is inherently a smaller power device.

So roughly speaking, in terms of size: steam turbine > gas turbine > internal combustion engine.

Different application scenarios

The difference in size directly determines the difference in their application scenarios.

The steam flow in the steam turbine is continuous and high-speed, and the flow rate per unit area is large, so it can generate a lot of power. In other words, it is used in larger-scale applications. High-power steam turbines use higher steam pressure and temperature, so the thermal efficiency is also higher. In other words, the unit cost is also lower, which is more cost-effective overall.

Therefore, steam turbines are preferentially used in industries that are large-scale, fixed in location, operate continuously, and are very cost-sensitive, the most typical of which is thermal power generation.

Steam turbines are also used in mobile facilities that have high power requirements (but are not sensitive to start-up time), such as super ships such as aircraft carriers.

Gas turbines directly output rotational motion, have high unit power, and start up quickly (no warm-up is required like steam turbines), so they are used in places where very high engine requirements are required, represented by jet aircraft and high-performance ships.

As you can imagine, internal combustion engines are mostly used in homes and other civilian scenarios, most notably in various cars, due to their small size and low power. Internal combustion engines are also widely used in various emergency situations, such as distributed energy systems such as backup generators.

Therefore, it is not difficult to imagine that large gas turbines represented by aircraft engines are the core of power equipment in the 21st century and are key technologies that mark the advanced level of national industrial manufacturing. Ultra-large gas turbines are recognized as the most difficult mechanical equipment to manufacture, representing the direction of high, precise and cutting-edge.

At the same time, large steam turbines that squeeze costs to the maximum extent, such as ultra-supercritical thermal power units, have become the basic power equipment for the country’s large-scale development of industrial manufacturing, representing a deep, thick and solid foundation.

The internal combustion engine technology, which focuses on lightness, quantity and smallness, has become the source of vitality for the country’s economic development, and directly determines the competitiveness of manufacturing industries such as the automobile industry that are widely related to the national economy and people’s livelihood.