01 Advantages of the integral blade

Before the emergence of the integral blade disk, the rotor blades of the engine needed to be connected to the wheel disk through tenons, mortise and tenon grooves and locking devices, but this structure gradually failed to meet the needs of high-performance aircraft engines. The integral blade disk that integrates the engine rotor blades and the wheel disk was designed, and has now become a must-have structure for high thrust-to-weight ratio engines. It has been widely used in military and civil aircraft engines and has the following advantages.

Weight loss

Since there is no need to machine the tongue and groove for installing the blades on the rim of the wheel disc, the radial dimension of the rim can be greatly reduced, thereby significantly reducing the mass of the rotor.

Reduce the number of parts

In addition to the fact that the wheel disc and blades are integrated, the reduction of locking devices is also an important reason. Aircraft engines have extremely strict requirements on reliability, and the simplified rotor structure plays a big role in improving reliability.

Reduce airflow loss

- The escape loss caused by the gap in the traditional connection method is eliminated, the engine working efficiency is improved, and the thrust is increased.

- The integral blade disk, which not only reduces the weight but also increases the thrust, is also conducive to improving the thrust-to-weight ratio. Naturally, it is not an easy “pearl” to pick. On the one hand, the integral blade disk mostly uses difficult-to-process materials such as titanium alloy and high-temperature alloy; on the other hand, its blades are thin and the blade shape is complex, which puts extremely high demands on manufacturing technology. In addition, when the rotor blades are damaged, they cannot be replaced individually, which may cause the integral blade disk to be scrapped, and the repair technology is another problem.

02 Manufacturing of the integral blade disk

At present, there are three main technologies for manufacturing integral blades.

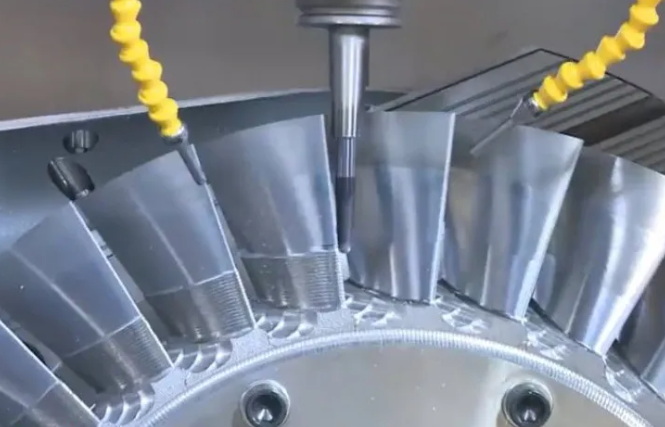

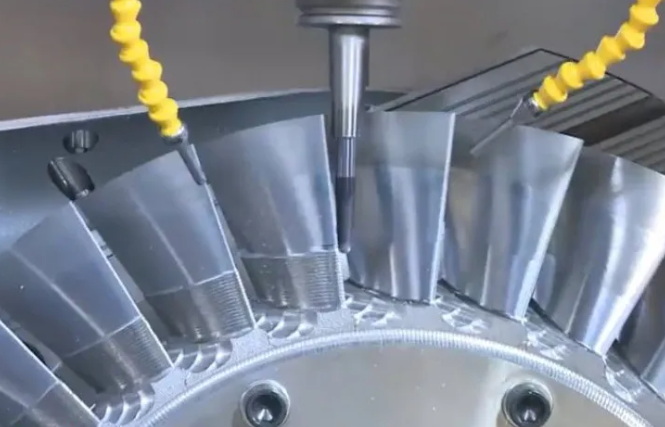

Five-axis CNC milling

Five-axis CNC milling is widely used in the manufacturing of blisks due to its advantages of rapid response, high reliability, good processing flexibility and short production preparation cycle. The main milling methods include side milling, plunge milling and cycloidal milling. The key factors to ensure the success of blisks include:

- Five-axis machine tools with good dynamic characteristics

- Optimized professional CAM software

- Tools and application knowledge dedicated to titanium alloy/high-temperature alloy processing

Electrochemical machining

- Electrochemical machining is an excellent method for machining the channels of integral blade disks of aircraft engines. There are several machining technologies in electrochemical machining, including electrolytic sleeve machining, contour electrolytic machining and CNC electrolytic machining.

- Since electrochemical machining mainly utilizes the property of metal dissolution at the anode in the electrolyte, the cathode part will not be damaged when the electrochemical machining technology is applied, and the workpiece during machining will not be affected by cutting force, machining heat, etc., thus reducing the residual stress of the integral blade channel of the aircraft engine after machining.

- In addition, compared with five-axis milling, the working hours of electrochemical machining are greatly reduced, and it can be used in the rough machining, semi-finishing and finishing stages. There is no need for manual polishing after machining. Therefore, it is one of the important development directions of aircraft engine integral blade channel processing.

Welding

- The blades are processed separately, and then welded to the blade disk by electron beam welding, linear friction welding or vacuum solid-state diffusion bonding. Its advantage is that it can be used for the manufacture of integral blade disks with inconsistent blade and disk materials.

- The welding process has high requirements on the quality of blade welding, which directly affects the performance and reliability of the overall blade disk of the aircraft engine. In addition, since the actual shapes of the blades used in the welded blade disk are not consistent, the positions of the blades after welding are not consistent due to the limitation of welding accuracy, and adaptive processing technology is required to perform personalized precision CNC milling for each blade.

- In addition, welding is a very important technology in the repair of integral blades. Among them, linear friction welding, as a solid phase welding technology, has high welding joint quality and good reproducibility. It is one of the more reliable and trustworthy welding technologies for welding high thrust-to-weight ratio aircraft engine rotor components.

Contact us

Thank you for your interest in our company! As a professional gas turbine parts manufacturing company, we will continue to be committed to technological innovation and service improvement, to provide more high-quality solutions for customers around the world.If you have any questions, suggestions or cooperation intentions, we are more than happy to help you. Please contact us in the following ways:

WhatsAPP:+86 135 4409 5201

E-mail:peter@turbineblade.net