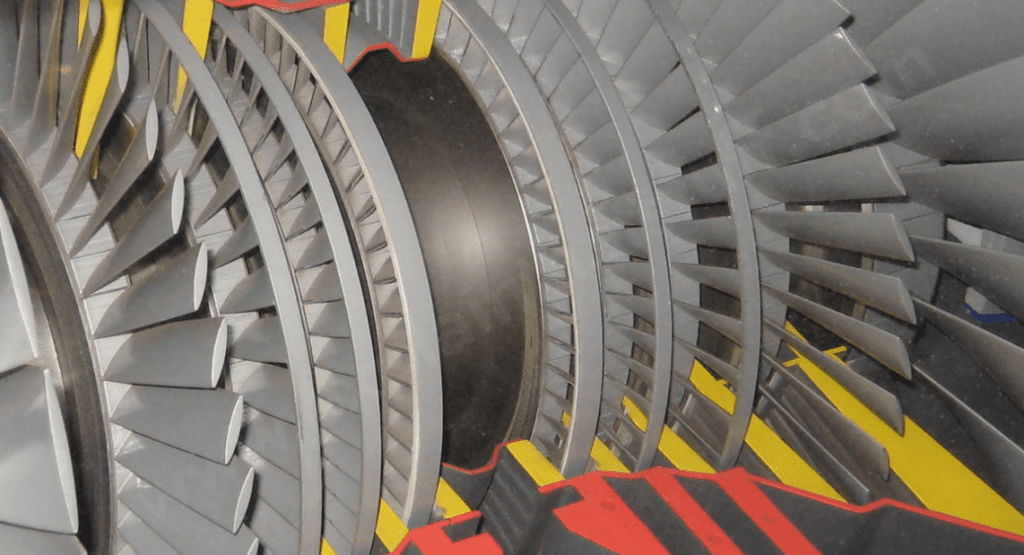

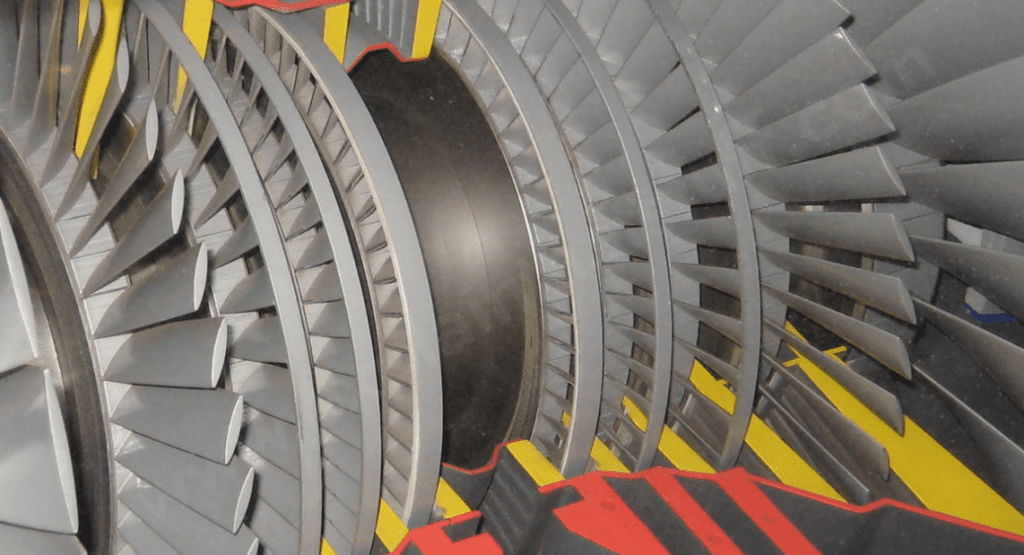

In the aerospace and power generation industries, where precision and durability are non-negotiable, the selection of materials for critical components is a matter of utmost importance. Among these, turbine blades are subjected to some of the most extreme conditions, including high temperatures, intense pressures, and significant mechanical stresses. Inconel 901, a superalloy renowned for its exceptional strength and heat resistance, has become a preferred choice for manufacturing high-performance turbine blades. This article explores why Inconel 901 is an ideal material for this application, delving into its properties, benefits, and the processes involved in its fabrication.

Understanding Inconel 901

Inconel 901 is a nickel-based superalloy that combines outstanding high-temperature strength with excellent corrosion resistance. Its composition includes approximately 42% Nickel, 23% Cobalt, 15% Chromium, 8% Molybdenum, 7% Tungsten, 2.5% Aluminum, 2% Titanium, and minor amounts of other elements. This unique blend results in a material capable of maintaining its structural integrity under conditions that would degrade or even destroy less robust materials. Specifically, Inconel 901 can withstand temperatures up to 1300°F (704°C) while retaining its strength and resisting oxidation, making it particularly suitable for use in jet engines, gas turbines, and other high-temperature environments.

Key Properties of Inconel 901

- High-Temperature Strength: One of the standout features of Inconel 901 is its ability to maintain high levels of strength at elevated temperatures. This characteristic is vital for turbine blades, which must endure the intense heat generated during operation without deforming or failing.

- Corrosion Resistance: The alloy’s high chromium content contributes significantly to its resistance against various forms of corrosion, including pitting, crevice, and stress-corrosion cracking. This property ensures longer service life and reduced maintenance costs.

- Creep Resistance: At high temperatures, metals tend to deform over time under constant load, a phenomenon known as creep. Inconel 901 exhibits superior creep resistance, ensuring that components remain stable and functional throughout their operational lifetime.

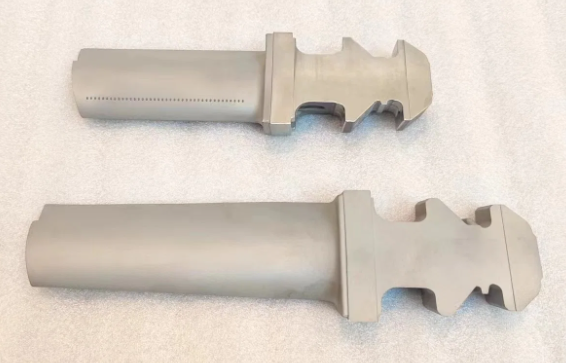

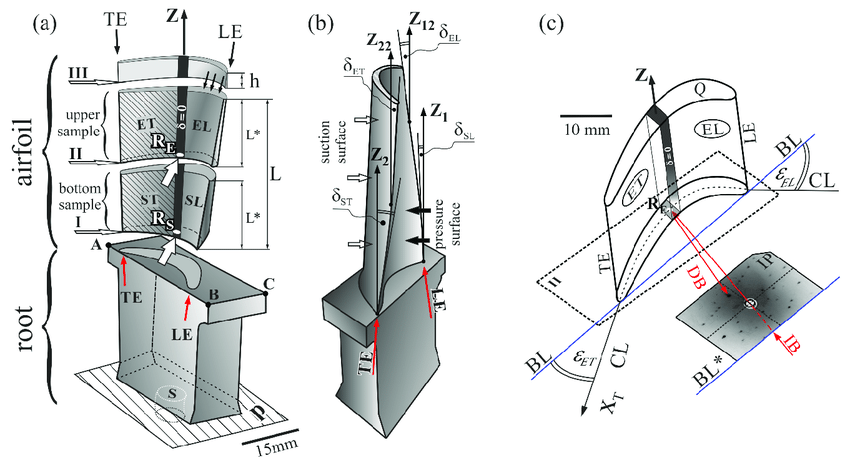

- Weldability and Fabrication: Despite its complex chemical makeup, Inconel 901 can be welded using standard techniques, although preheating and post-weld heat treatment may be necessary to achieve optimal results. It also responds well to forging, machining, and casting, allowing for the creation of intricate designs and shapes required for modern turbine blades.

Applications of Inconel 901 in Turbine Blade Manufacturing

Turbine blades, especially those used in aircraft engines and industrial gas turbines, operate in extremely harsh environments characterized by rapid temperature changes, exposure to corrosive gases, and continuous mechanical stress. In such settings, the selection of Inconel 901 offers several advantages:

- Enhanced Performance and Reliability: By leveraging the material’s inherent properties, manufacturers can produce turbine blades that not only meet but exceed performance expectations, leading to more efficient and reliable engine operations.

- Extended Lifespan: Thanks to its excellent wear and corrosion resistance, Inconel 901 helps extend the lifespan of turbine blades, reducing the frequency of replacements and associated downtime.

- Customizability and Design Flexibility: The versatile nature of Inconel 901 allows designers to create innovative blade geometries aimed at optimizing aerodynamic efficiency and overall system performance, thereby contributing to advancements in turbine technology.

Challenges and Considerations

While Inconel 901 presents numerous benefits, working with this material does come with certain challenges. These include higher costs compared to conventional alloys, as well as the need for specialized equipment and expertise in processing and finishing. However, given the critical role played by turbine blades in safety-critical applications, the investment in quality materials like Inconel 901 is often justified by the enhanced reliability and performance they provide.

Advanced Manufacturing Techniques

To fully harness the potential of Inconel 901, advanced manufacturing techniques such as directional solidification and single crystal growth are employed. These methods ensure that the material’s microstructure is optimized for maximum strength and durability. Additionally, additive manufacturing, or 3D printing, is increasingly being used to produce complex turbine blade geometries with unprecedented precision and efficiency. These technologies not only improve the performance of the blades but also reduce material waste and production time.

Maintenance and Life-Cycle Management

Proper maintenance and life-cycle management are essential for maximizing the longevity and performance of Inconel 901 turbine blades. Regular inspections, non-destructive testing (NDT), and condition-based monitoring help identify and address any issues before they become critical. Implementing a robust maintenance program, including scheduled overhauls and repairs, can further extend the service life of the blades, ensuring long-term reliability and cost-effectiveness.

Conclusion

- In conclusion, Inconel 901 represents a pinnacle in material science, offering a perfect balance of strength, heat resistance, and durability needed for today’s high-performance turbine blades. As technology continues to evolve, so too will the demand for advanced materials capable of pushing the boundaries of what is possible. With its proven track record across multiple industries, Inconel 901 stands ready to play a pivotal role in shaping the future of aerospace and power generation technologies.

- For more information on Inconel 901 and how it can benefit your specific application. Our team of experts is dedicated to providing you with the highest quality materials and solutions tailored to your needs. Whether you are looking for custom-made turbine blades, technical support, or a consultation, we are here to assist you every step of the way. Let us help you unlock the full potential of Inconel 901 and take your projects to new heights.