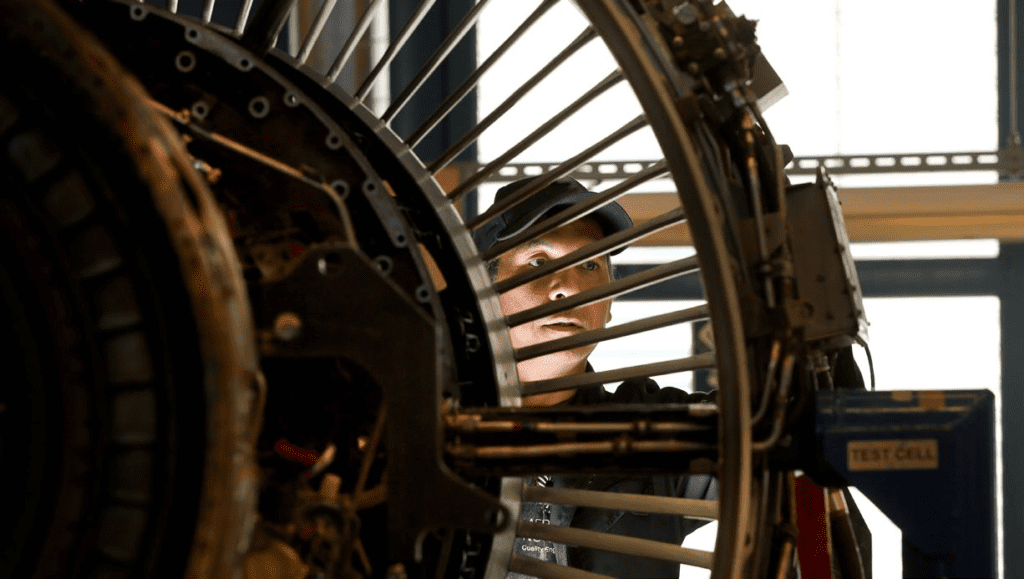

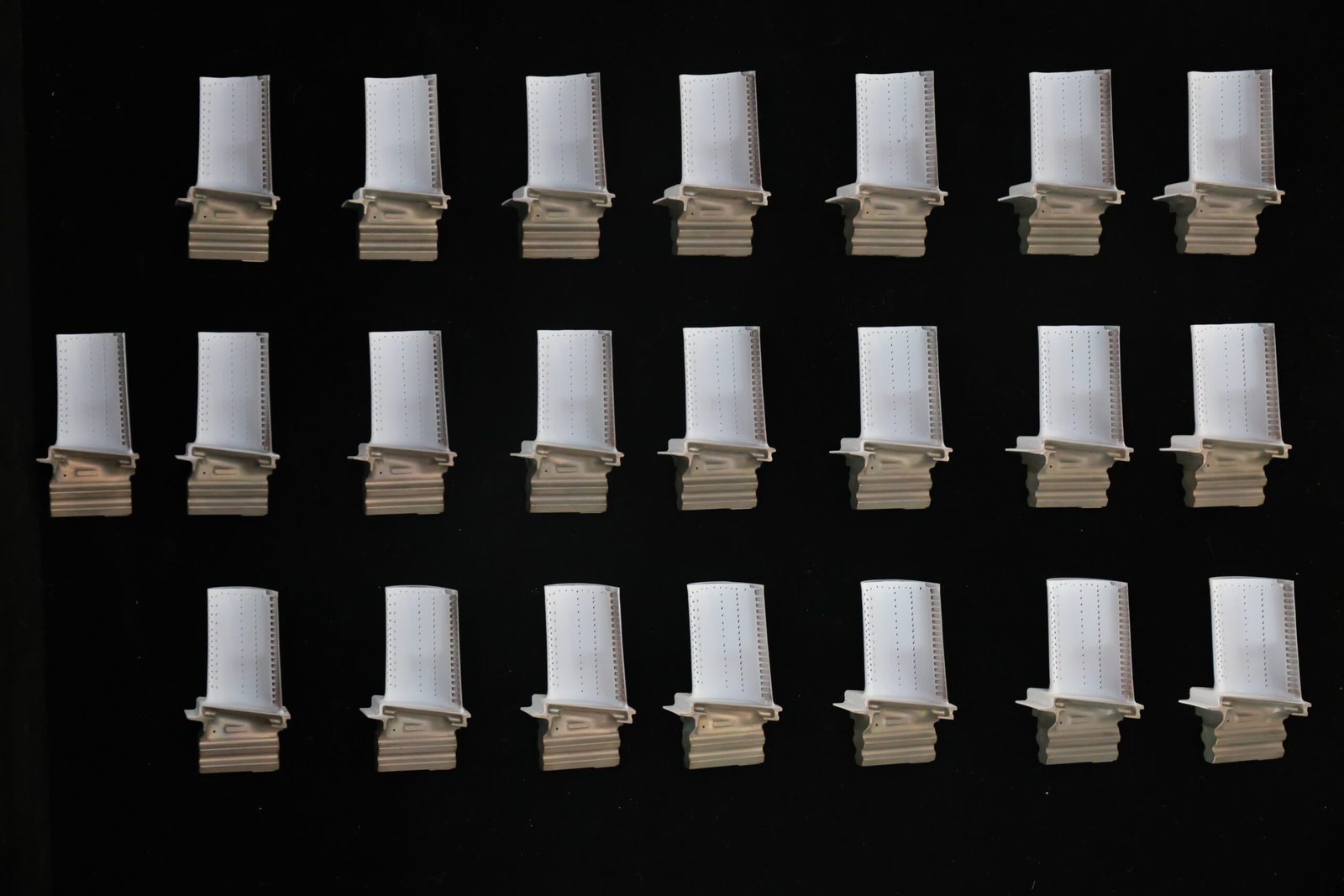

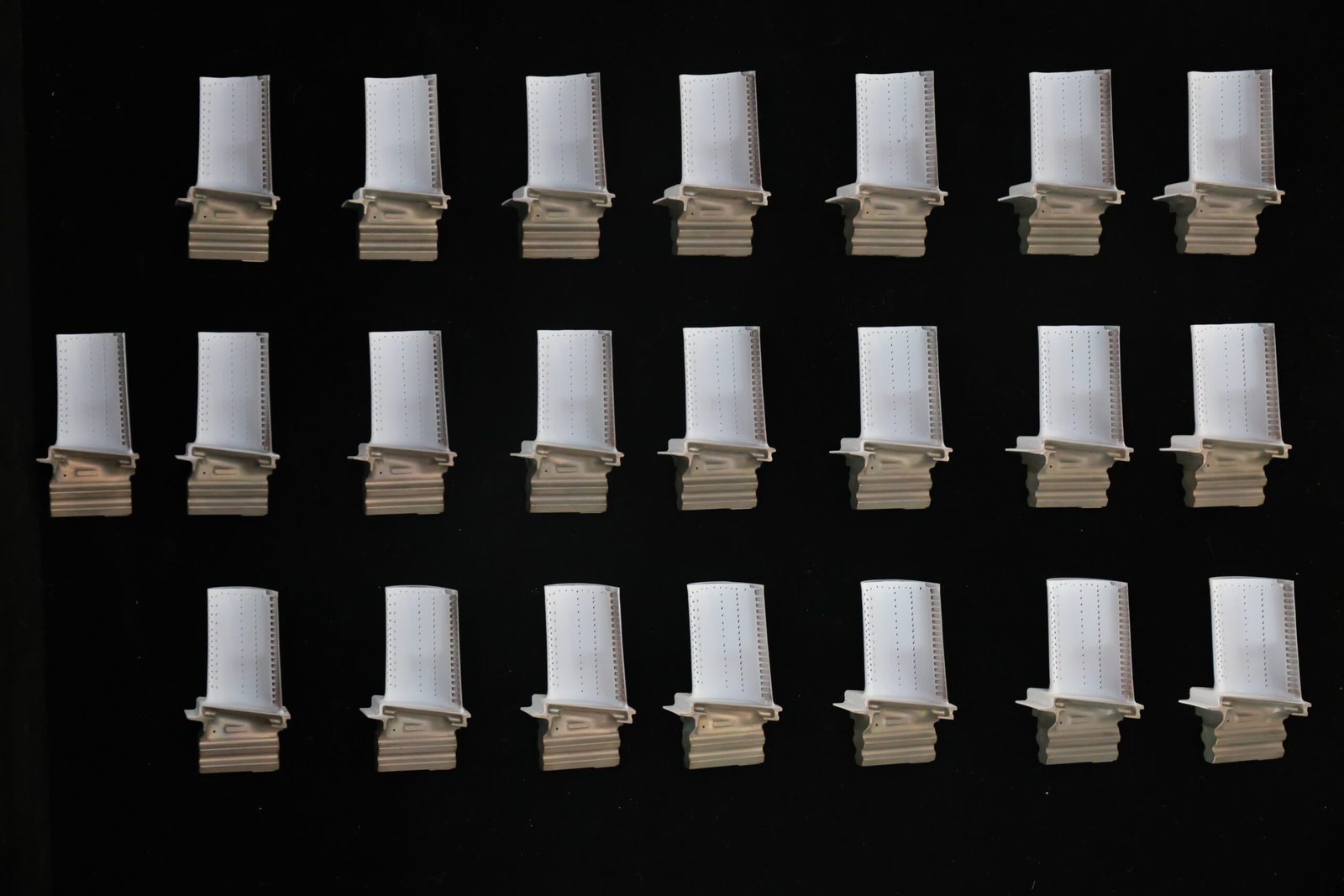

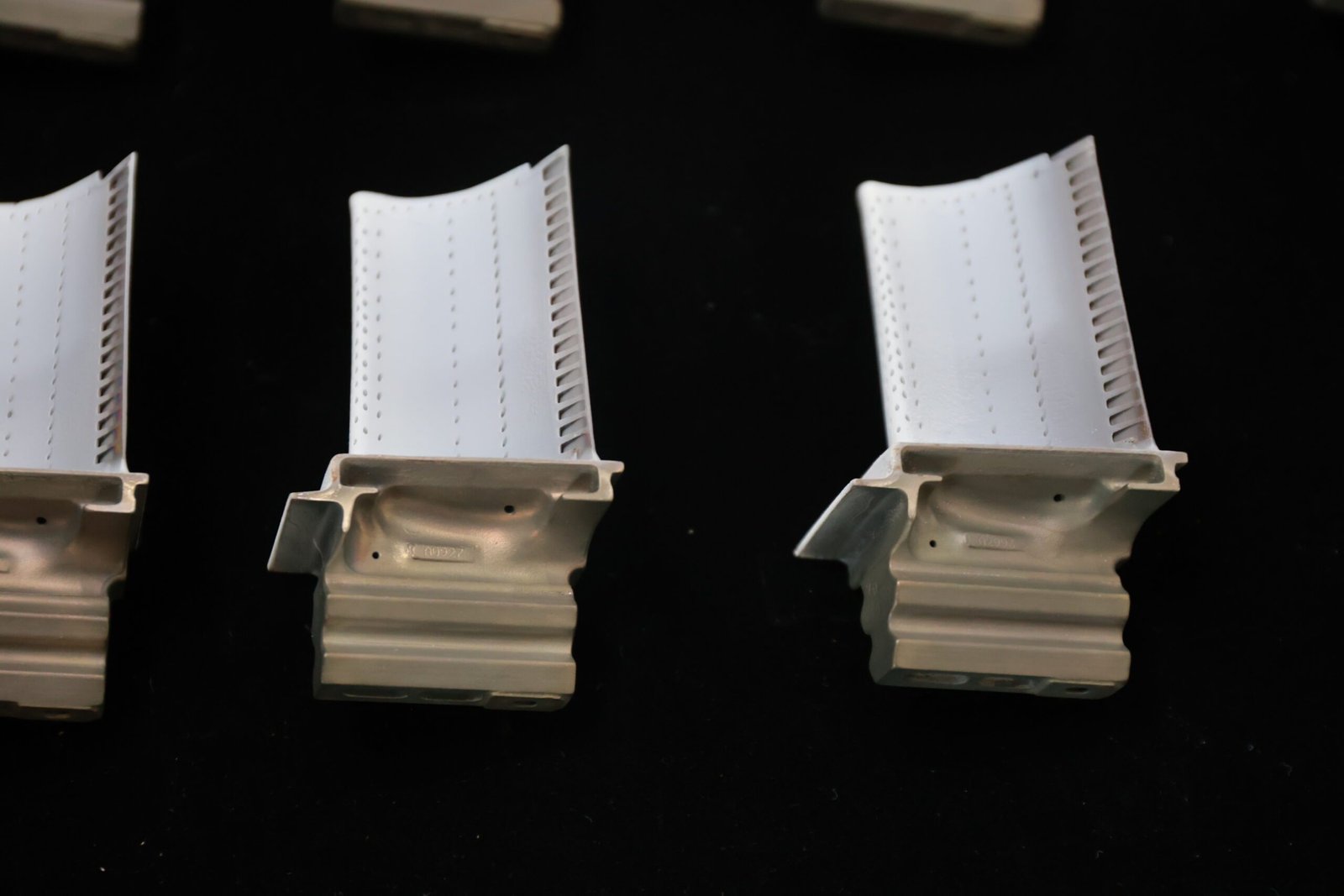

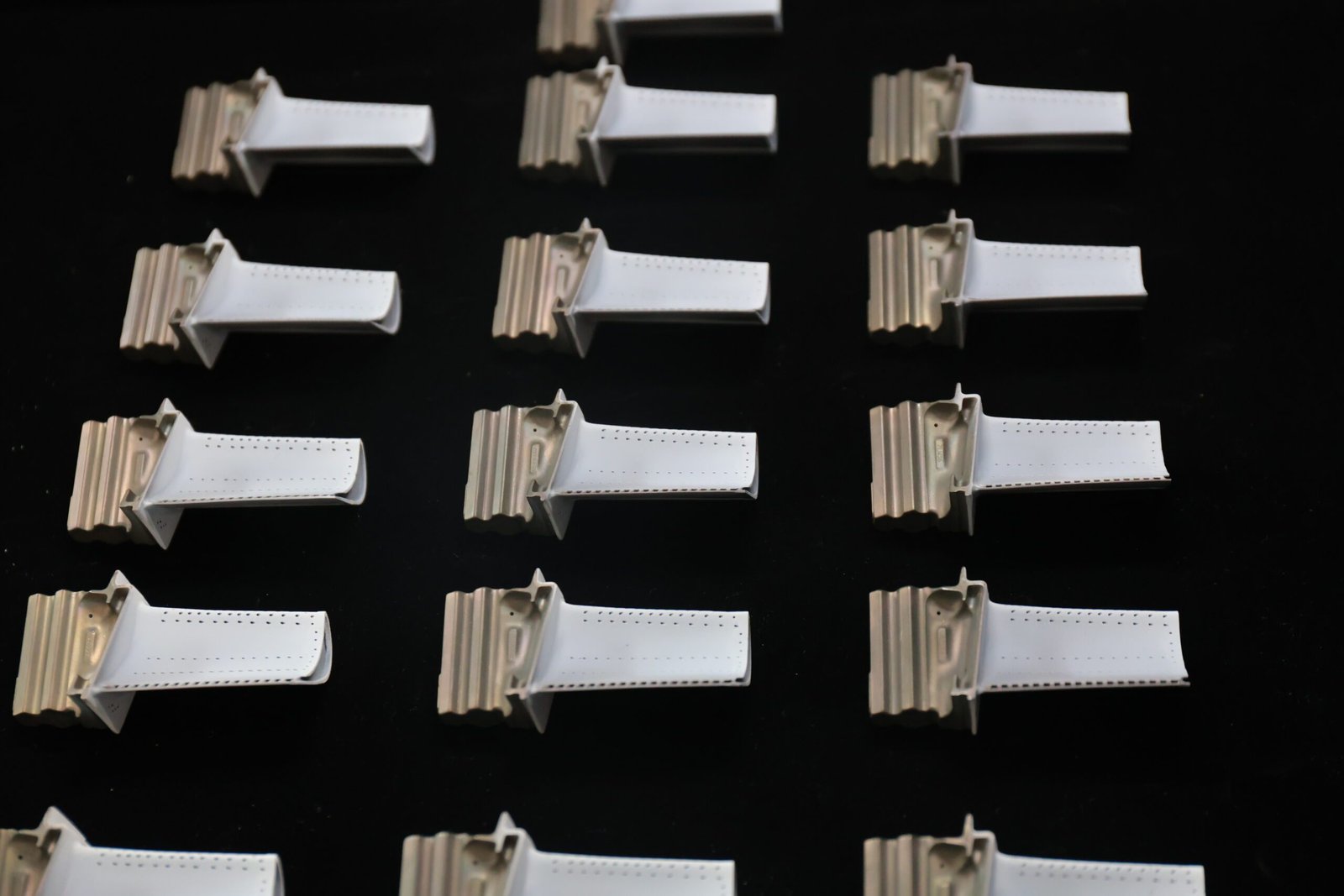

We restore worn and damaged turbine blades to serviceable condition through an advanced multi-stage process.

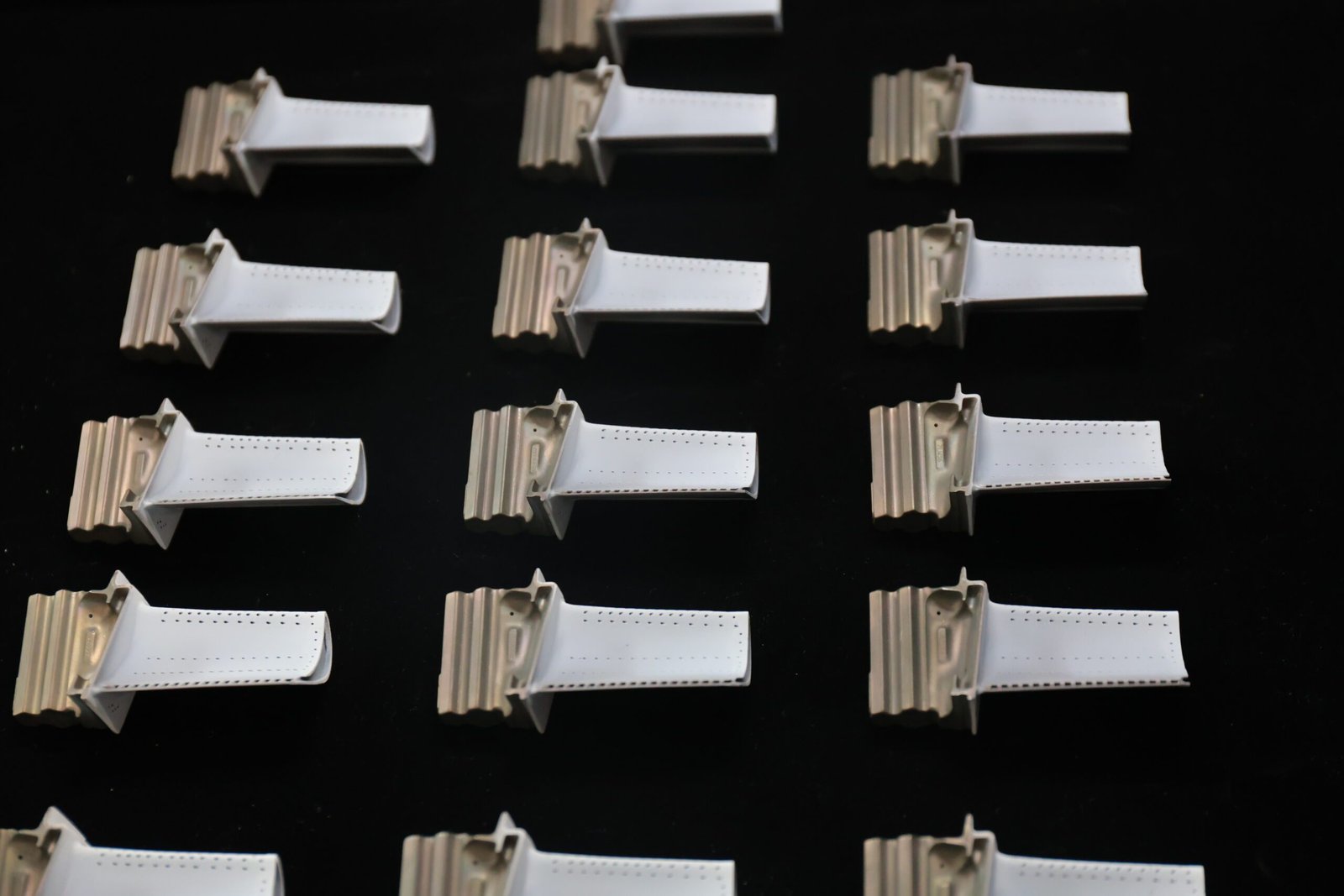

Each blade undergoes rigorous inspection using advanced NDT methods, dimensional verification, and material testing to guarantee airworthiness. Our refurbishment meets or exceeds CFM International specifications for the CFM56-3, -5B, -5C, and -7B engine series.

Supported HPT Blade Numbers:

2084M33P02, 1475M35P01, 2080M87P04, 2080M87P06, 2080M87P07, 2403M91P05, 2100M96P03, 2100M96P05, 2080M81P01, P104P42, 2403M91P05 etc.

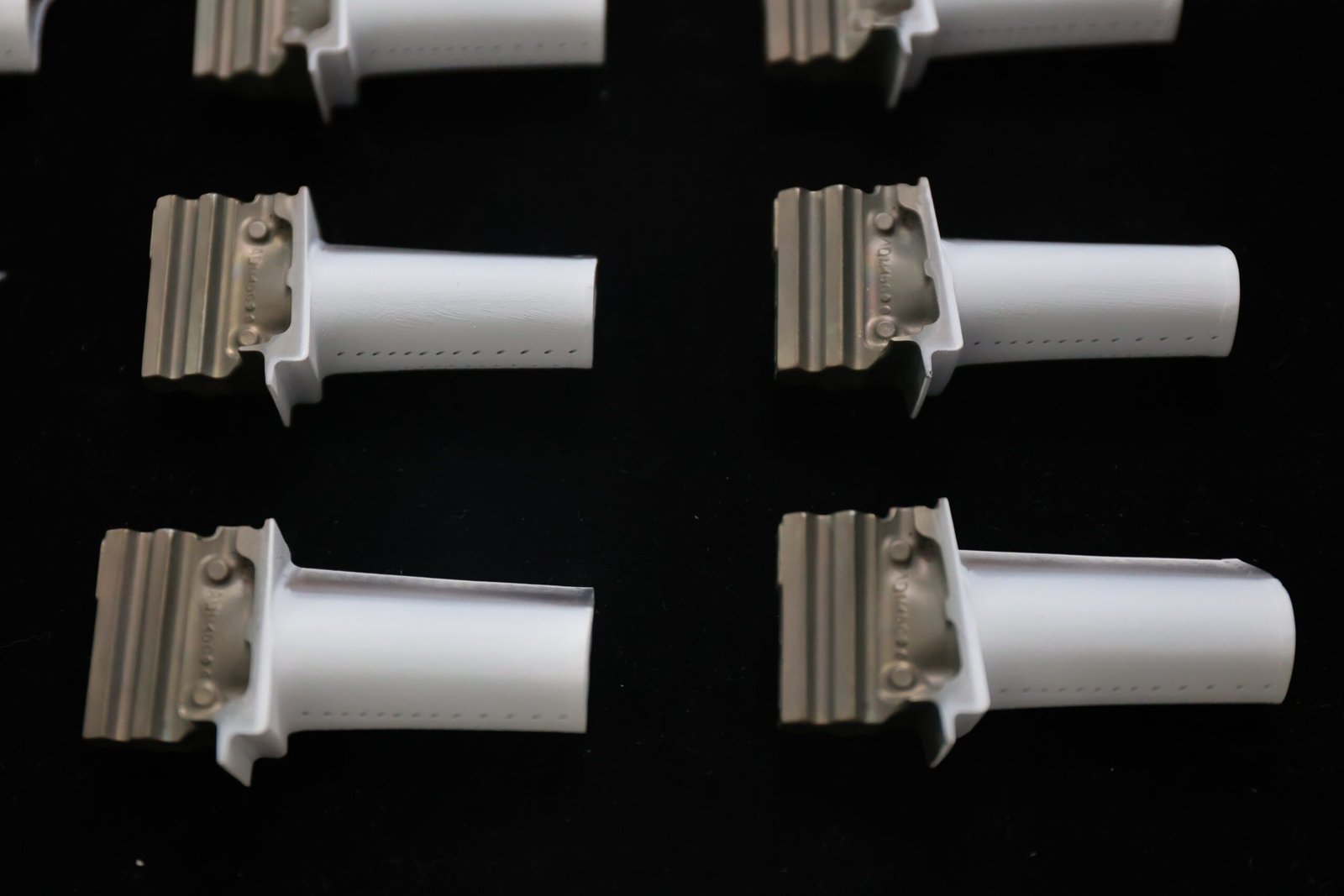

CFM56 turbine blade refurbishment is a cost-effective process that extends blade service life while maintaining OEM standards.

The procedure includes:

Keep your CFM56 fleet flying with our full-spectrum maintenance, repair, and overhaul solutions. From routine inspections to complete overhauls, we deliver world-class engine care tailored to your operational needs.

What We Offer

Customized maintenance solutions for fleets of any size—whether you operate two engines or two hundred. Our advanced facilities support all CFM56 variants (CFM56-2, CFM56-3, CFM56-5A/B, CFM56-7B) with proven expertise and cutting-edge technology.

Maximum Value

Lower fuel costs, extended time on wing, and reduced maintenance expenses CFM International—that’s the CFM56 advantage. Our MRO services preserve these benefits while minimizing downtime and optimizing your operational budget.

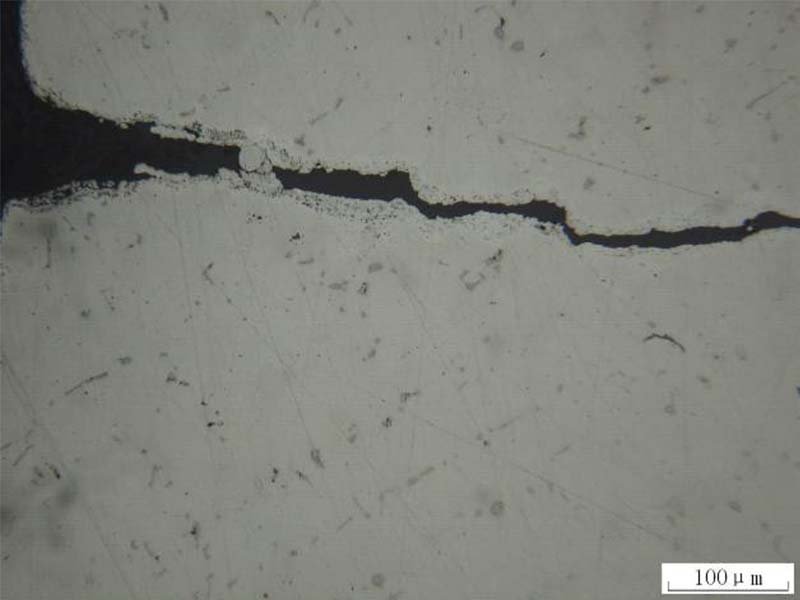

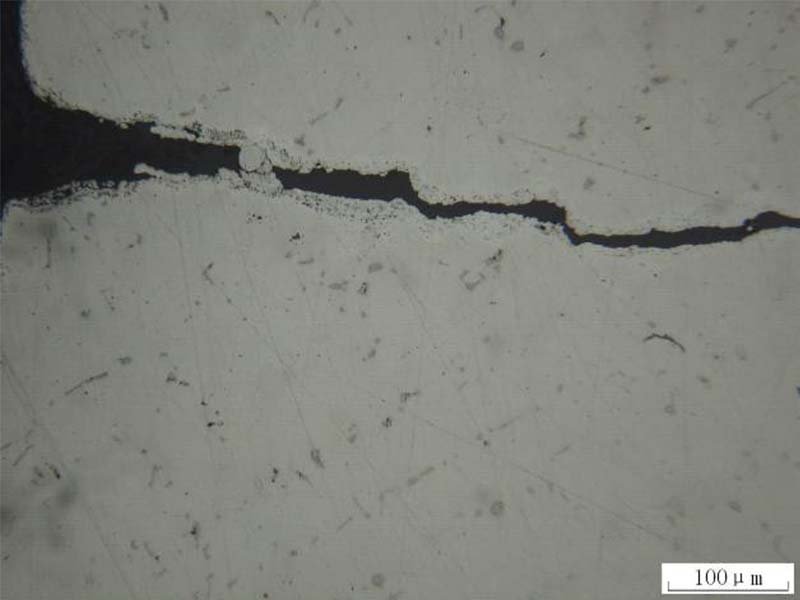

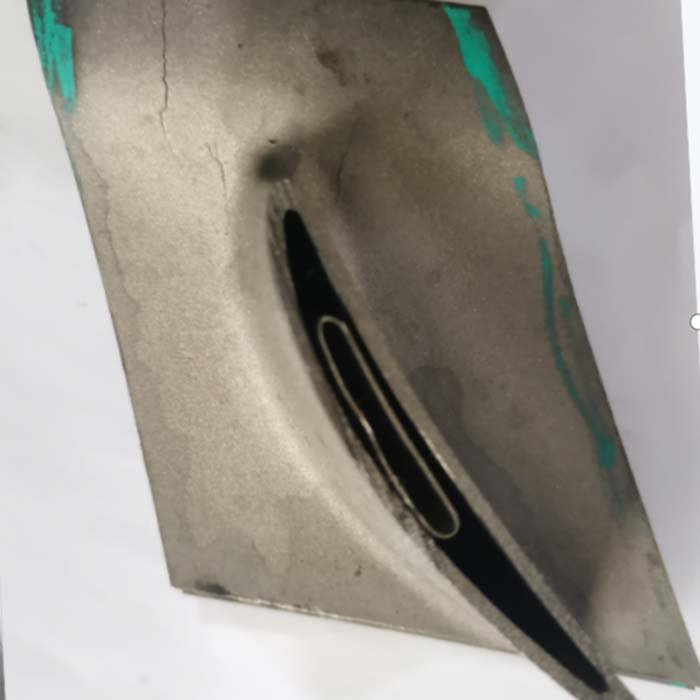

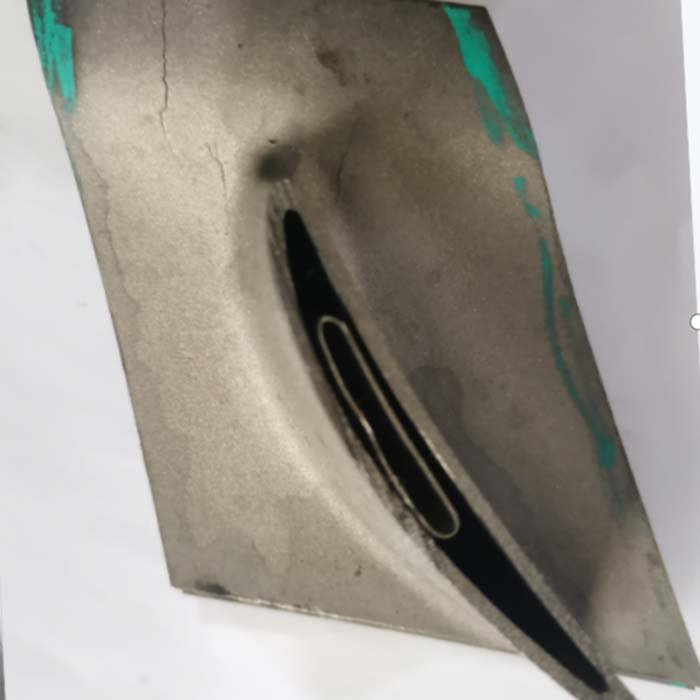

Fluoride ion cleaning technology is an efficient surface cleaning method, widely used in precision manufacturing, electronics, aerospace and other fields. This technology uses the chemical properties of fluoride to remove oxides on the blade surface and oxides deep in the cracks through chemical reactions or physical actions, greatly reducing the maintenance cost of aircraft engines, greatly improving maintenance efficiency, and solving the processing and repair problems of aircraft engine and gas turbine blades.

Crack tip oxide film pulsed fluoride ion ultra-low damage cleaning technology.

Fluoride ion cleaning technology is an efficient surface cleaning method, widely used in precision manufacturing, electronics, aerospace and other fields. This technology uses the chemical properties of fluoride to remove oxides on the blade surface and oxides deep in the cracks through chemical reactions or physical actions, greatly reducing the maintenance cost of aircraft engines, greatly improving maintenance efficiency, and solving the processing and repair problems of aircraft engine and gas turbine blades.

Crack tip oxide film pulsed fluoride ion ultra-low damage cleaning technology.

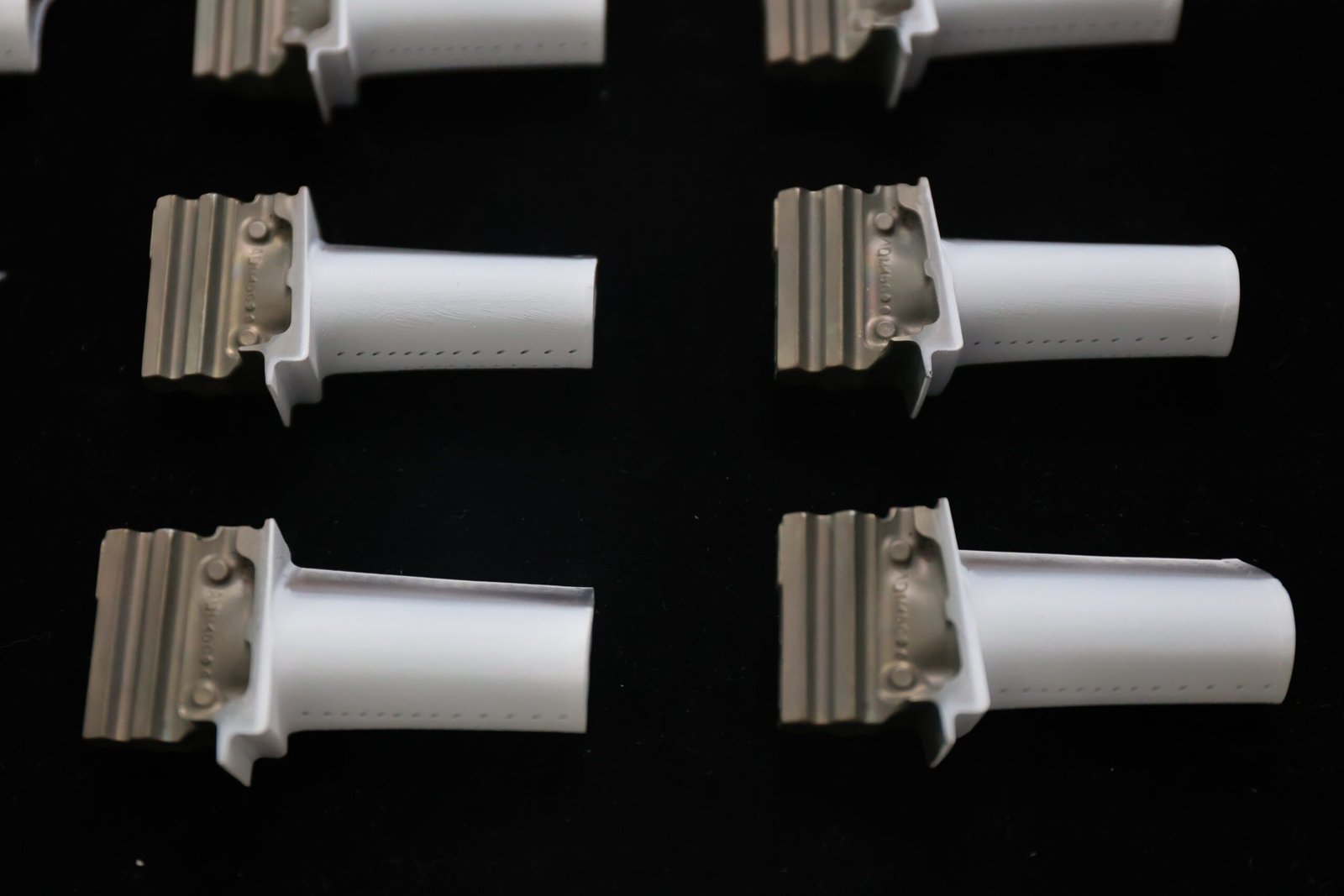

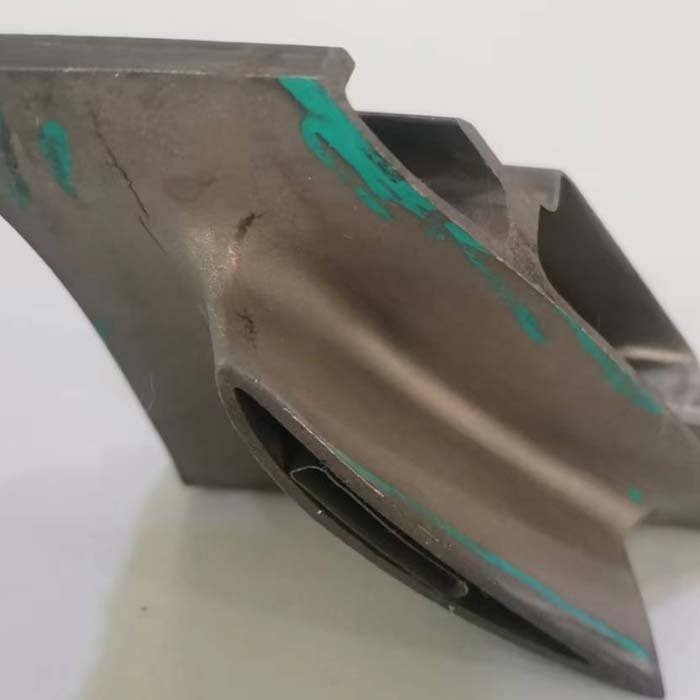

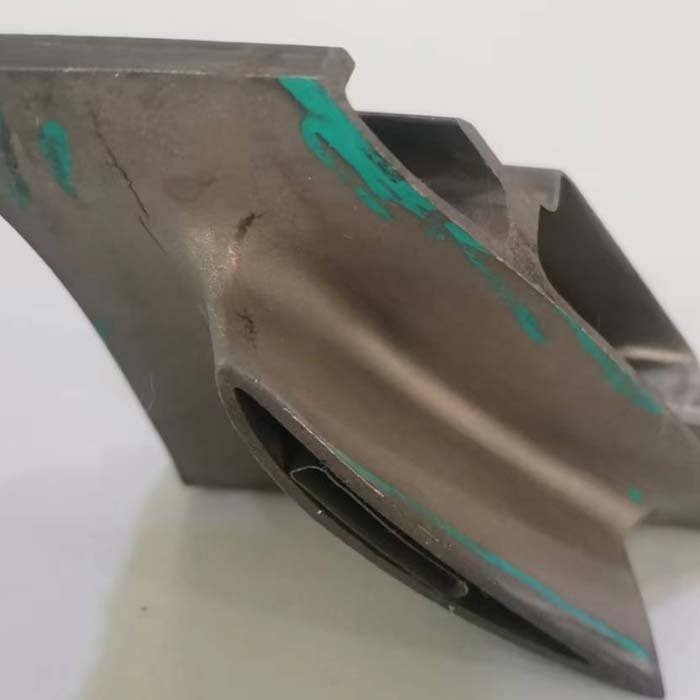

Our factory used GHL-6-2 brazing filler metal to repair the cracks with large gap brazing. After brazing, the excess brazing filler metal and solder resist on the surface of the repaired part were cleaned by manual polishing. From the appearance, the crack surface has been completely covered by the brazing filler metal.

In order to clarify the surface state of the repaired part, a local fluorescent penetration inspection was carried out. The inspection results are shown in the Fluorescence inspection picture of the blade surface repair area. It can be seen that the original cracking parts of cracks A and B and the nearby brazing filler metal coating locations are displayed in dense dot patterns.

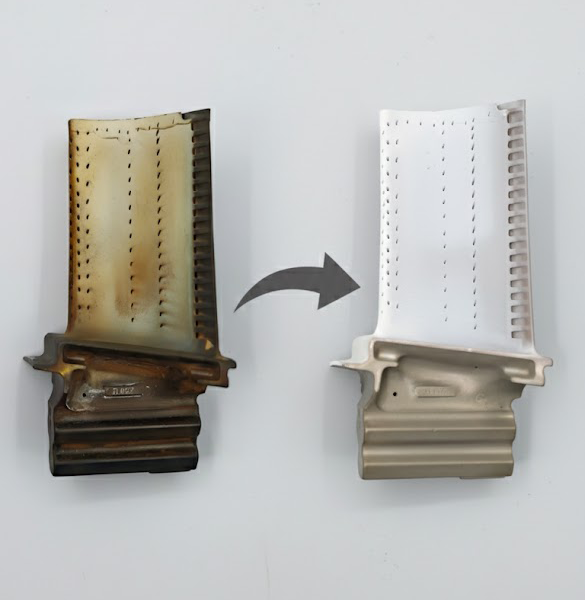

Before cleaning: Turbine blade surface may be covered with oxide layers, oil, dust or other contaminants, causing the surface to look dull, mottled or uneven.

Contaminants and oxide layers may shorten the life of the blades and increase the frequency of maintenance and replacement.

After cleaning: The blade surface becomes brighter and more uniform, and the contaminants and oxide layers are removed, making the surface look cleaner and smoother.

Cleaning removes harmful substances, which can extend the service life of the blades and reduce maintenance costs

Part numbers alone are not sufficient to ensure performance.

To guarantee precision and compatibility, please provide:

Drawings or used samples for reverse engineering.