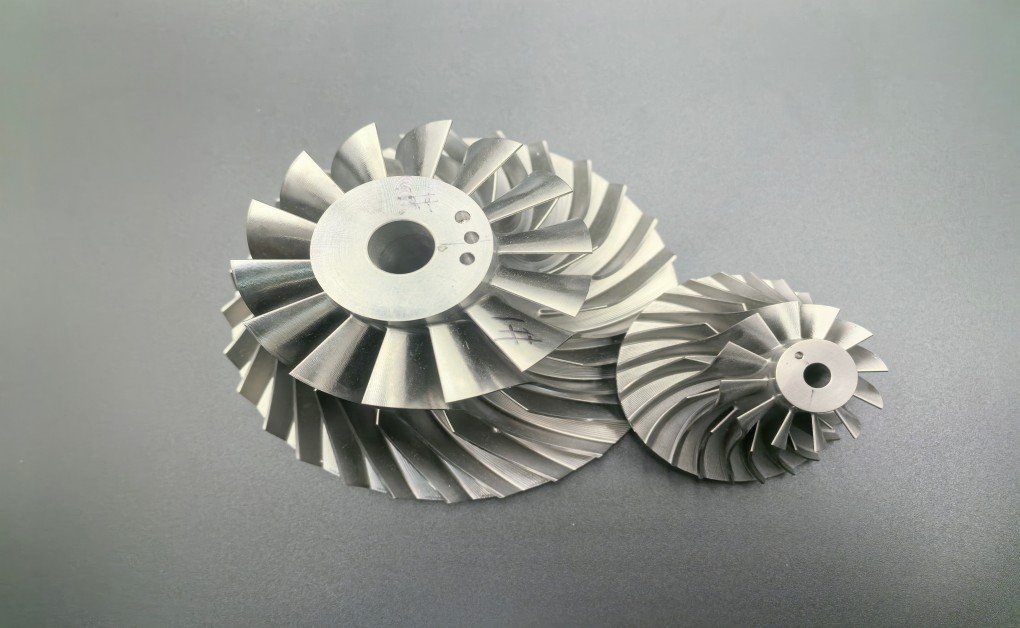

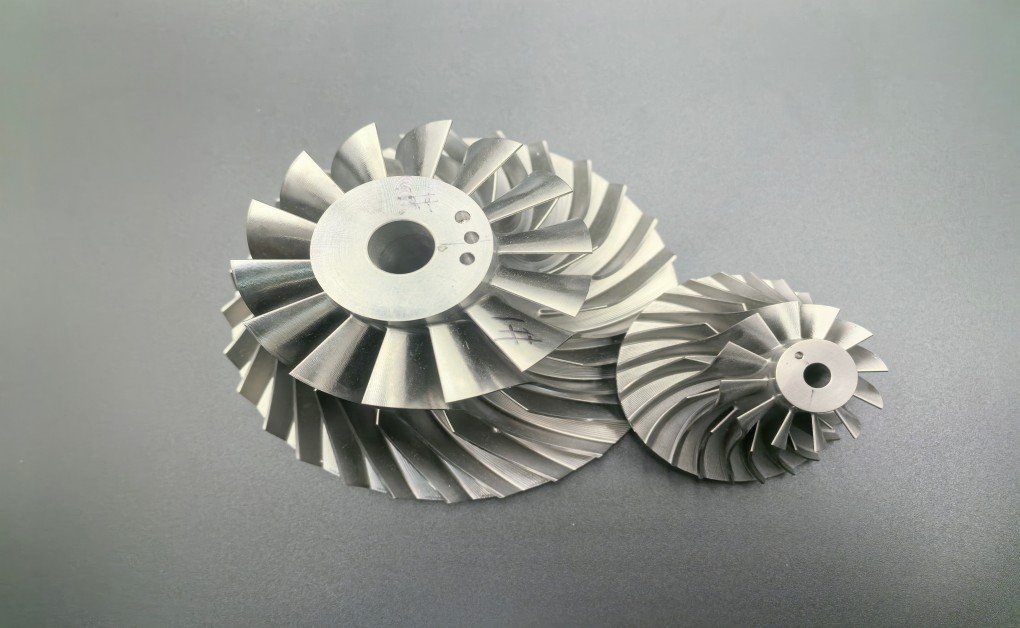

In modern industry, gas turbines are a core power source for many critical applications, including power generation, aerospace and Marine propulsion. As a foreign trade company focusing on the customization of gas turbine parts, we rely on strong reverse research and development capabilities and rich experience in customization, to provide high-quality, high-performance solutions for global customers. This article will demonstrate our excellence in the manufacture of rough forged turbine wheels through a real customer case.

1.Customer background and needs

Our customer is an internationally renowned aero engine manufacturer whose engines are widely used in civil aircraft. With the development of technology and the intensification of market competition, customers want to further improve the performance and reliability of engines. Especially for this critical component, the turbine wheel, the customer needed a solution that could withstand extreme operating conditions while providing greater efficiency.

2.Project initiation and analysis

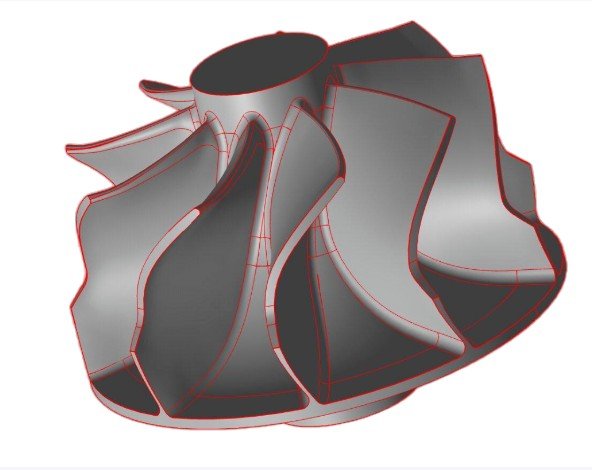

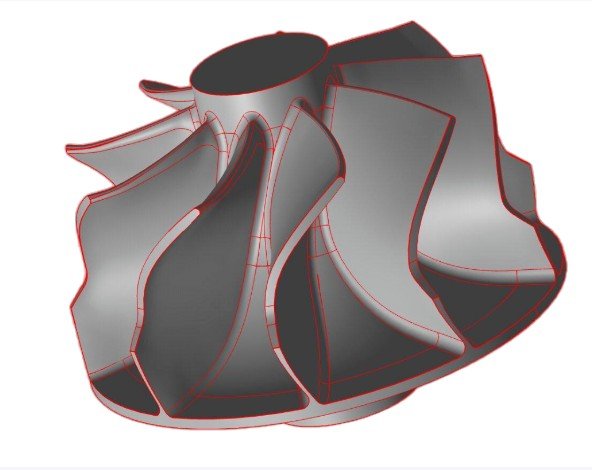

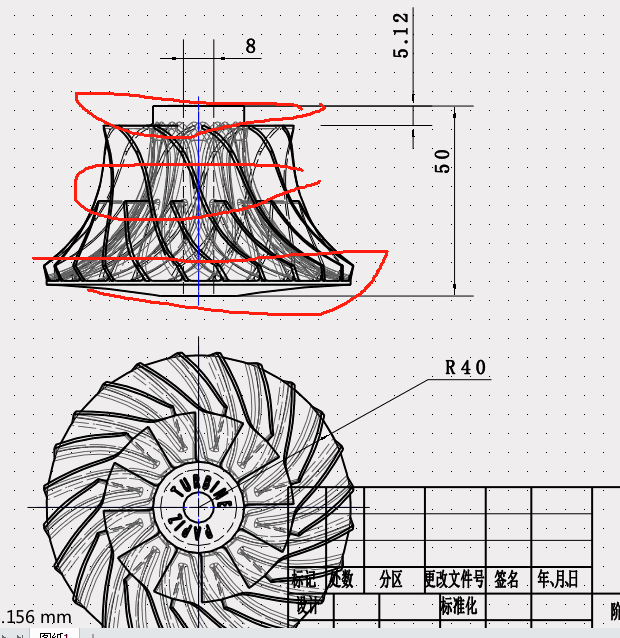

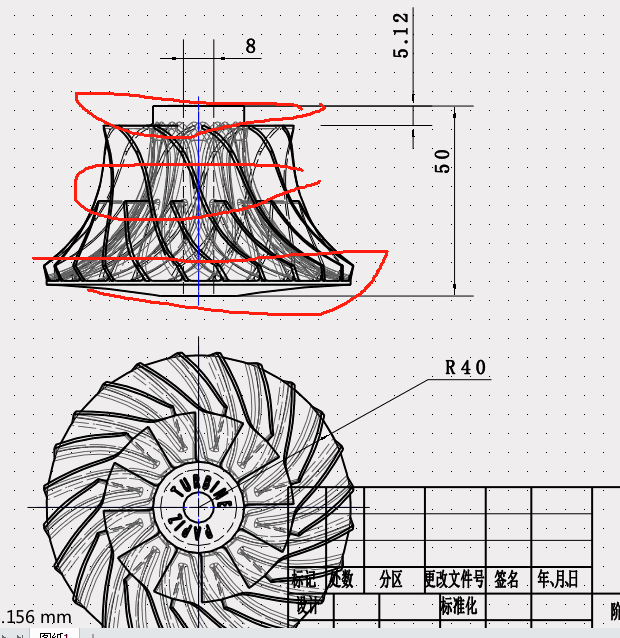

Upon receiving the customer’s request, our technical team moved quickly to conduct a comprehensive reverse engineering analysis of the existing turbine wheels supplied by the customer. Through high-precision 3D scanning and material testing, we document in detail the design parameters, material properties and manufacturing processes of the original parts. This process not only helped us to accurately understand the structural characteristics of the original part, but also identified its potential for improvement.

3.Optimized design and custom development

Based on the reverse engineering data, our design team set out to optimize the turbine wheel design. Through hydrodynamic simulations and thermodynamic analysis, we identified several key improvements:

- Blade Shape optimization: Through CFD (computational Fluid dynamics) simulation, we optimize the shape of the blade to improve aerodynamic efficiency and reduce drag.

- Material selection : The selection of high-strength, high-temperature resistant Ti-6Al-4V, this material has better mechanical properties and fatigue resistance.

- Cooling system improvement : The internal cooling channel has been redesigned to enhance the heat dissipation effect and extend the service life of the components.

4.Advantages of rough forging process

In order to achieve the above design objectives, we adopt the rough forging process. Rough forging is an efficient metal forming method that can form complex geometric shapes while maintaining material properties. To be specific:

- Mold design: We have designed a special forging mold to ensure the accuracy of the internal structure of the casting.

- Temperature control: With a precision temperature control system, we achieve a one-time forming from billet to finished product, reducing subsequent processing steps.

- Heat treatment: After forging is completed, we carry out a strict heat treatment to further improve the mechanical properties of the material.

The advantages of the rough forging process are:

- Higher strength: The material flow during rough forging refines the grains and improves the strength and toughness of the material.

- Better consistency: Rough forging ensures consistency for each part and reduces differences between batches.

- Cost effective: Compared to traditional casting or CNC machining, the rough forging process is more cost effective in mass production.

5.Delivery and verification

After months of hard work, we successfully produced the first custom-made rough forged turbine wheels and delivered them to the customer on time. After installation and commissioning, the new turbine wheels performed well, not only meeting the expected performance indicators, but also surpassing the original parts in some aspects. Especially in long-run tests, the new parts demonstrated increased reliability and longer service life, significantly reducing maintenance costs and downtime for customers.

6.Customer feedback and cooperation prospects

The customer spoke highly of this collaboration, believing that our customized solution not only solved their immediate needs, but also brought long-term cost savings and technical advantages. They particularly appreciate our expertise in design optimization, material selection and manufacturing processes. Based on this successful collaboration, the client has decided to establish a long-term partnership with us and plans to further cooperate on more projects in the future.

Thank you for your interest in our company! As a professional turbine parts manufacturing company, we will continue to be committed to technological innovation and service improvement, to provide more high-quality solutions for customers around the world.If you have any questions, suggestions or cooperation intentions, we are more than happy to help you. Please contact us in the following ways:

- WhatsAPP:+86 135 4409 5201

- E-mail:peter@turbineblade.net